Dion in digital groove

Dion Label Printing was an early adopter of HP Indigo technology and seven years later is still leading the digital label field, writes Danielle Jerschefske

Since first installing an HP Indigo ws4000 press in 2005, Dion Label has printed over one billion labels digitally. By investing in digital technology at an early stage, Dion Label has established itself in a variety of smaller, more specialized markets, some with technical needs that require digital printing knowledge and expertise. The over-the-counter pharmaceutical, nutraceutical and medical markets make up a good piece of the business. It also produces labels for the food and beverage markets, private label candle companies and industrial applications.

In high value niche work, the converter has found a sweet spot in producing multiple SKUs and shorter runs. President John Dion says, ‘there has been no application that we haven’t been able to put through digital. And we have had zero complaints with quality.’

Digital rise

Dion Label runs two HP Indigo WS6000 digital presses, finishing on an ABG Digicon Series I and two Delta Industrial Mod-Tech lines, complemented by a series of narrow-web flexo presses. Jobs have been shifted to digital where this is a better fit, opening up analog capacity.

Right now the two production sides are about split equally in terms of revenue, yet two thirds of items are printed digitally. ‘And that trend continues,’ explains Dion. ‘Most new jobs coming in are digital jobs. It’s a trend that follows the sort of work that we do – variations, more runs becoming shorter with more frequent changeovers.’

Dion Label marketing manager Stacy Santos says, ‘We don’t necessarily market towards digitally printed labels. We’re just finding that digital is becoming more and more a fit for typical orders and that more of the work out there is falling into where digital fits best.’

At numerous Labelexpo Series conferences and Dscoop (Digital Solutions Cooperative) sessions in recent years, digital has been described as ‘much more predictable’ by veteran digital label printers, including Dion Label. Randy Duhaime, general manager, says, ‘When it comes to a more difficult job, there’s just more that can go wrong on the analog end with plates, inks, anilox rolls, waste and uptime. Analog could end up being double what was quoted. When it comes to digital, the set up is the set up.

‘Efficiency and waste are independent of job complexity when it comes to digital. There’s not a direct relationship. You can use as many colors as you want. You can use as many elements printed adjacent to each other as you want. That all has a direct bearing on how well the job is going to go in analog where there are many more considerations.’

Real run-lengths

Digital label converters are most commonly asked: what is your average run length? The answer is, ‘if it fits the bill, it will run digital’. Dion Label has completed projects for various applications with run lengths between 30-45,000 feet. It has produced paper jobs in excess of 80,000 feet, and jobs have been on a press for three days – highly complex with 10 SKU's, screen printing, hot stamping and a couple of varnishes. Duhaime says, ‘Still the average run length is below 5,000 feet.’ A job may involve as many as 30 different items with 30 different tickets all using the same die and all done as different jobs. Duhaime explains, ‘Each is 2,000 feet, but all together the job is longer.’

Brands, converters and denial

The majority of brands, all sizes and markets, are not ‘digitally aware’. It’s common to find brand managers, their marketing teams and label buyers with a bias against digital. They just don’t believe that the technology can meet their requirements for color matching, quality print and consistency. Dion Label encountered a situation with a client that passed digital tests for matching color, but once the buyer realized the order would be printed digital, they changed their mind and demanded flexo.

Brands can realize great savings and other benefits when they’re in the know about digital printing. For example; one of Dion Label’s customers ordered a medium sized run of labels to be printed digitally. Duhaime explains, ‘They decided to go digital even though the initial run would have been cheaper to go analog. But anticipating future runs where there may be multiple SKU's and smaller runs, they decided to start with digital from the beginning. They understood that they may pay more now, but that future runs would actually be cheaper than analog.’

Shortly after the initial order the client thought of things to change on the outside of the package for the next run, and won’t have to re-do and pay for new plates. ‘They’re an educated buyer. You don’t always have that.’

Shrink

Most recently Dion Label has invested in shrink sleeve converting and finishing capability. The converter had been looking at getting into the market for years and was outsourcing shrink sleeve label production for customers. It eventually started by printing shrink labels in-house and can now complete the sleeving as well.

Santos says, ‘We have been shy to market ourselves as "experts" in printing shrink sleeves. Now that we have successfully completed multiple shrink sleeve projects, we feel comfortable pursuing this market.’

The strategy has been to go after existing customers that currently use the decoration technique rather than going through new clients with trial and error. Duhaime explains, ‘We wanted to be proficient in the process before aggressive marketing.’

The incremental move was possible because of the economical entry-level package offered by Karlville that includes a seamer and inspection unit, software, and a steam box for prototyping and testing distortion.

Says Duhaime, ‘the equipment is ideal for short run work without any issues. We may grow out of it soon, but it will last us a year or two as we transition into the space.’

Right now Dion Label has limited orders to PETG film material only. Dion says, ‘It’s mostly what’s been asked for and PVC is not something that we want to bring into our plant.’ The converter has long recycled its solid waste with International Paper to be reprocessed into fuel pellets as an alternative to coal. PVC cannot be turned into energy pellets to burn. Dion Label would rather turn the business away, as it is typically a bit cheaper and higher volume, not the high value niche work it’s accustomed to.

‘We had to really work on the price and see our way to figuring out how to get it down,’ explains Dion. ‘Shrink typically runs on larger presses, but we’re able to achieve better print quality with analog flexo or digital. The labels are much more vibrant. And there’s no comparison in the registration and quality.’ The converter is able to print analog shrink sleeves for jobs wider than 13 inches – the width of the HP Indigo WS6000 machines – up to 16 inches on an MPS press, which is good for long run jobs of a couple hundred thousand feet.

Narrow vs. mid-web

Dion Label has not made any investments in analog since 2008. Says Dion, ‘We’re not giving up on analog, but it also hasn’t been a driver of growth, and it’s not clear that it makes sense to push further into it.’

HP Indigo made its leap into the mid-web printed package market at drupa, announcing the development of two new lines with widths of 30 inches and 29.5 inches respectively designed for producing shorter runs of flexible packaging and folding cartons. Continues Dion, ‘If we make a successful foray into flexible package printing then this would be the natural first step, to operate and invest in tooling for such modern digital equipment.

‘Still, with changeovers for machinery that wide, everything else that you do needs to be wider, bigger beefier, and heavier, and we do not have that space right now. Even thirteen inch is wide enough for plenty of the jobs out there, and almost too wide. These jobs will never be suitable for such packaging machines built for serious orders that go out in the millions.’ Dion reiterates, ‘We’re looking for safe little niches that have some difference that is well suited to digital or some special technical feature that we can apply.’

Finishing with value

Dion Label has used an ABG Digicon Series 1 finishing machine since it entered the digital printing market. In the fall of 2008 it installed a full rotary Delta Industrial Mod-Tech as a back up for medical products production. The converter initially wanted semi-rotary, but found that full rotary was the way to go with the work going on the line hitting speeds up to 250 feet/min while die cutting and laminating. Duhaime says, ‘It was getting jobs done in half the time.’

Through the digital upswing Santos, marketing manager, ultimately discovered new opportunities and potential customers with a great interest in foiling, hot stamping, multiple coatings and laminates, and it was a market that Dion Label wanted to delve further into. With its in-line analog equipment the converter could produce hot stamp and cold foil finishes, but had nothing for short run finishing with higher decoration techniques.

In February 2012 Dion Label installed a monster of a machine with a customized fully servo Delta Mod-Tech that is completing work at speeds between 200-300 feet/min. The strength of the converting machinery supplier’s engineering breadth is apparent in every inch of the line.

Dion’s new Mod-Tech has the first flatbed hot stamp unit and silk screen unit of their kind to be placed into the market, with software modified to suit the converter’s needs. The finishing unit has two line guides to support the long web path, a special lift for loading and unloading dies, a visual inspection camera, and sheeter that can be switched between both Delta machines. Already the converter has found value in printing an analog job of 145,000 feet to be sheeted on the Delta running at 275 feet/min.

Dion says, ‘The flat bed hot stamping and embossing unit will make such finishing much more cost effective for almost everything we could ever run, since the rotary embossing requires a high initial investment.’

Digital Prepress

While prepress for digital printing is generally simpler, it does need to be automated, and Dion Label uses Labeltraxx MIS software to streamline the digital workflow.

Dion Label's customer service is responsible for completing the initial job setup, including job specs and file names. Dion says, ‘Having the job specs completed earlier in the process helps in other areas along the way. Files need to be defined correctly up front if we want efficiency.’ Intensive training has made the customer service team more technically knowledgeable. They’ve been taught, for instance, that it’s important to fill the print frame properly on the digital press for efficiency. Additionally, all of the file planning is completed up front: if the job has multiple SKU's, if it requires ganging with multiple items across, and this is all done by customer service. For exact repeat digital jobs the order is just sent along.

Armed with this experience, a talented team, deep market knowledge, and a proven willingness to be an early adopter of advanced technology, the Massachusetts-based converter will continue to remain a leader of the pack in both North American and global label markets.

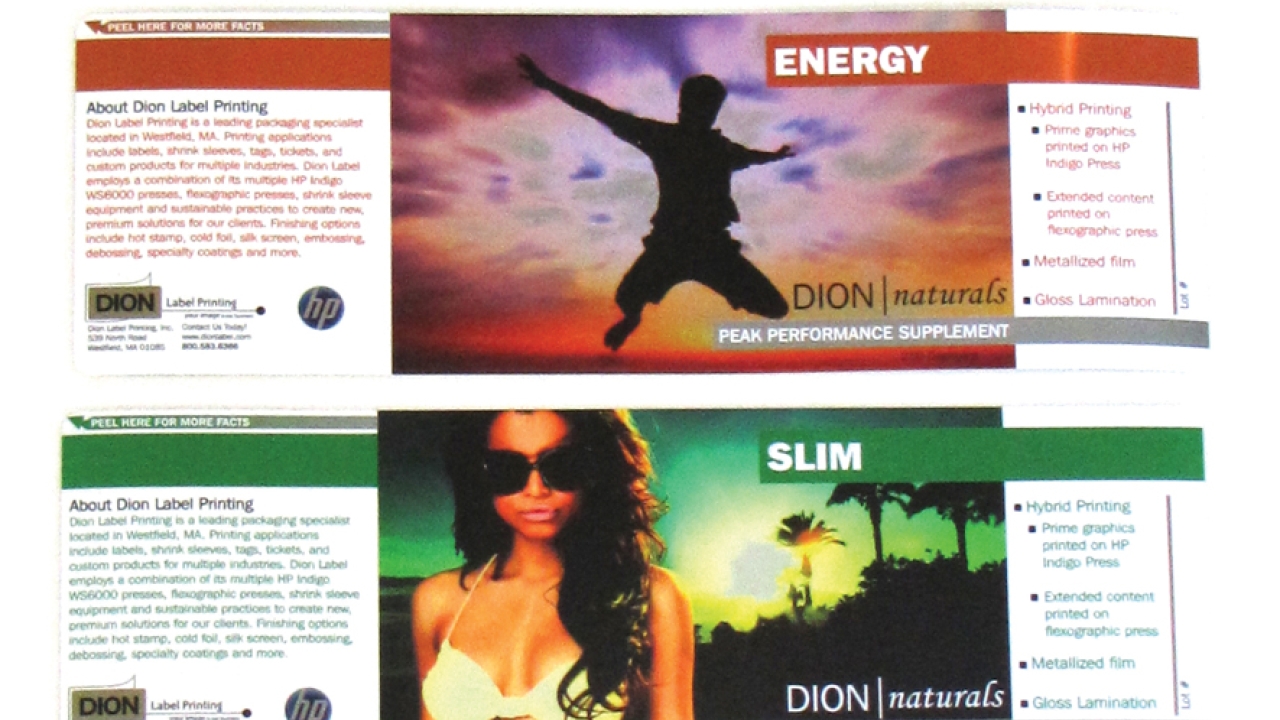

Pictured: Dion can produce complex labels with high quality graphics

This article was published in L&L issue 5, 2012

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.