Cheshire Anilox invests in Microdynamics interferometry systems

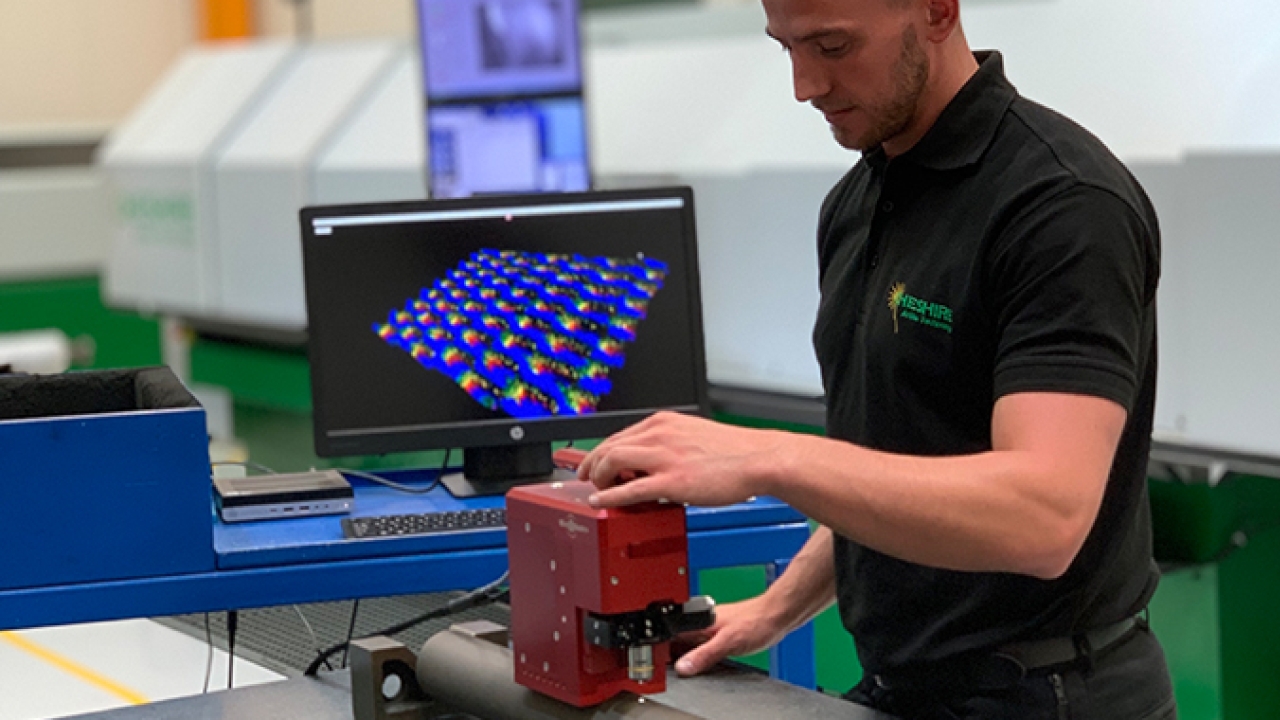

Cheshire Anilox Technology has invested in interferometry systems by Microdynamics.

The company assessed other volume control systems available, but reportedly found Microdynamics to be the most consistent method.

Microdynamics is a digital interferometry system that uses a series of reflective light waves, with accuracy as fine as 10 nanometers, capturing cross sections of the engraving and composing a 3D image of the cells resulting in a true volumetric measurement.

Having the proper cell volume is necessary for accurate color reproduction. In order to monitor consistently cell volume it is important to use an advanced and fully automatic scanning measurement system that does not rely on operator inspection alone, said Cheshire.

‘The need to get the latest technology with the Microdynamics interferometer microscope was crucial to us as it allows us to get a fully calibrated volume control system and full integration between readings of different types of microscopes which is an essential part or our Quality control procedure,’ said Phil Smith, Cheshire Anilox Technology production manager.

‘With the recent investments in volumetric and quality control, Cheshire can assure their customers worldwide repeatability and consistency from roll to roll. This is critical for global print groups that are looking to standardize their production between plants,’ said Sonia Arcos, Cheshire’s technical sales director.

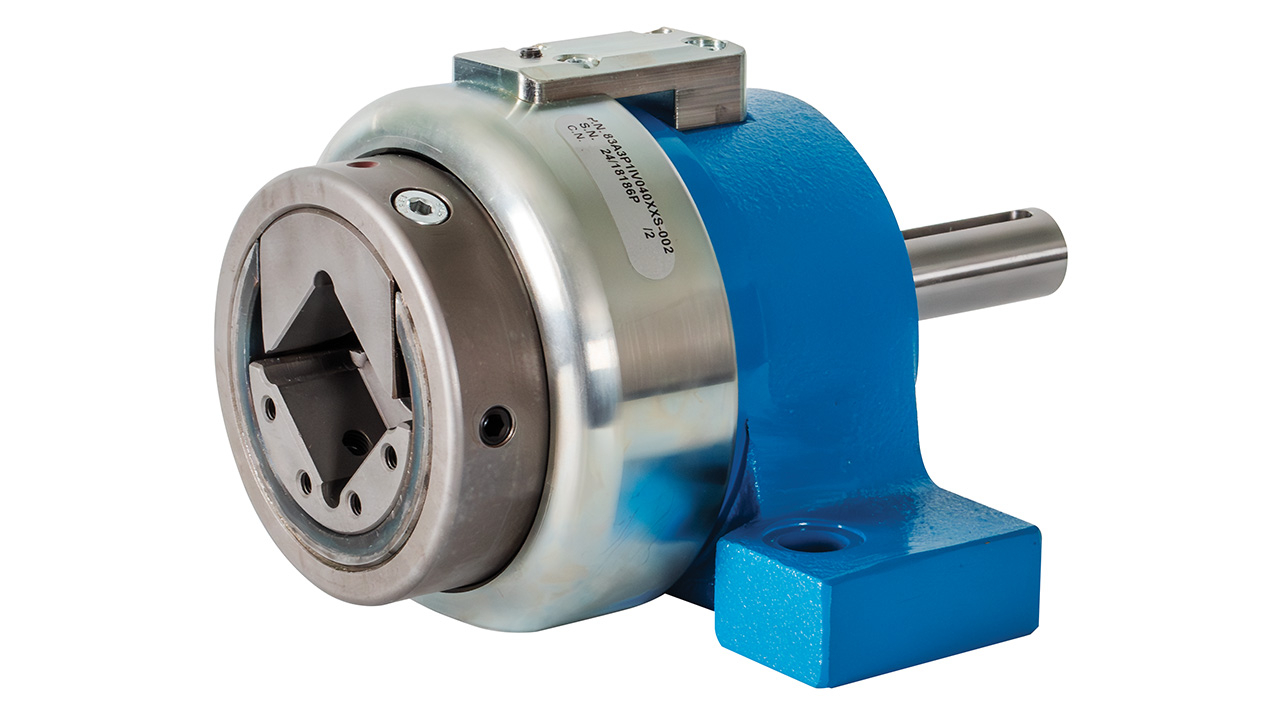

The new measurement system complements recent investments in engraving technology, enabling Cheshire to produce reliable and consistent anilox rolls and sleeves.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.