Clondalkin makes first mass carton serialization investment

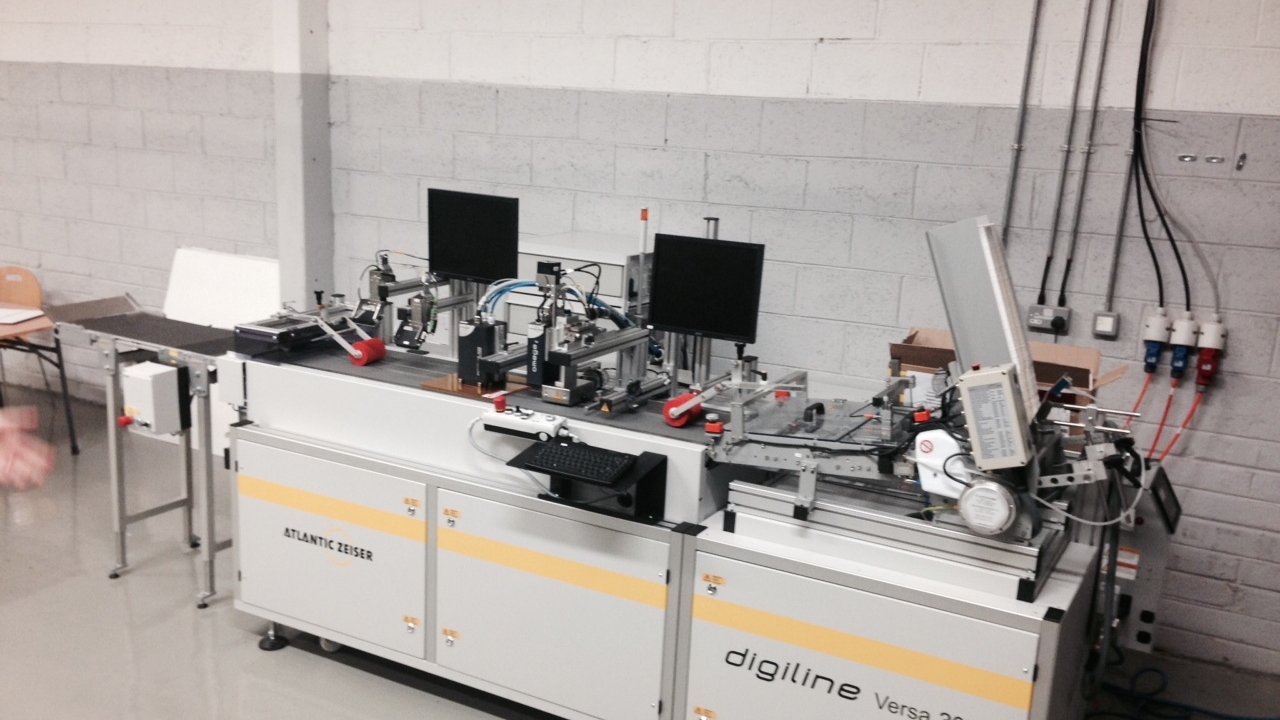

Clondalkin Pharma & Healthcare has installed its first mass carton serialization capability at its Cherry Orchard facility in Dublin in the form of an Atlantic Zeiser Digiline Versa 300.

The finished cartons are fed into a coding stream that utilizes a printhead and UV dryer allowing fast coding speeds, while the twin VeriCam camera data inspection system verifies application. This facilitates application, code verification to the master data and readability. An automated rejection process is also included.

From its three facilities in Ireland, Clondalkin Pharma & Healthcare produces a wide range of printed components from cartons, labels and leaflets to clinical trial extended content labels to customers across Ireland, the UK, Europe and the US.

The Atlantic Zeiser Digiline Versa 300 has also allowed Clondalkin Pharma & Healthcare to introduce track and trace technology for new serialization standards. Clondalkin Pharma & Healthcare said the investment supports track and trace capability for product movement, and provides authentication, improved brand protection and increased consumer confidence.

Mark Rooney, chief operating officer at Clondalkin Pharma & Healthcare Specialist Packaging division (SPD), which was recently acquired by Essentra, said: ‘Many pharmaceutical companies are responding to the challenge of serialization standards by upgrading or installing lines capable of applying a track and trace identifier, but this is often confined to 2D barcoding and batch specific data.

‘We have the capability to individually code products of various sizes including flat cartons both glued and unglued. The system can receive and manage multiple data files and print multiple codes. The wide printhead with multiple image print capability in direction of feed allows 2D matrix and code 128 possible in separate locations once within same print width profile. Should the need occur additional printheads can be added to extend the print location capability.

‘The two separate camera verification scanning units ensure quality of code read and verification of code, or multiple code to the master input data.’

Malcolm Farnan, sales and marketing director at Clondalkin Pharma & Healthcare SPD Europe, added: ‘Continued investment is required in order to respond and provide solutions that make it easier for our customers to meet regulation without compromising on efficiency and quality. Our customers approach us to provide solutions from regulatory changes to efficiencies.

‘There are both mass market and niche market demands that are best supported by a competent and experienced packaging supplier rather than in-house.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.