Italian manufacturer invests in KBA for the production of luxury packaging

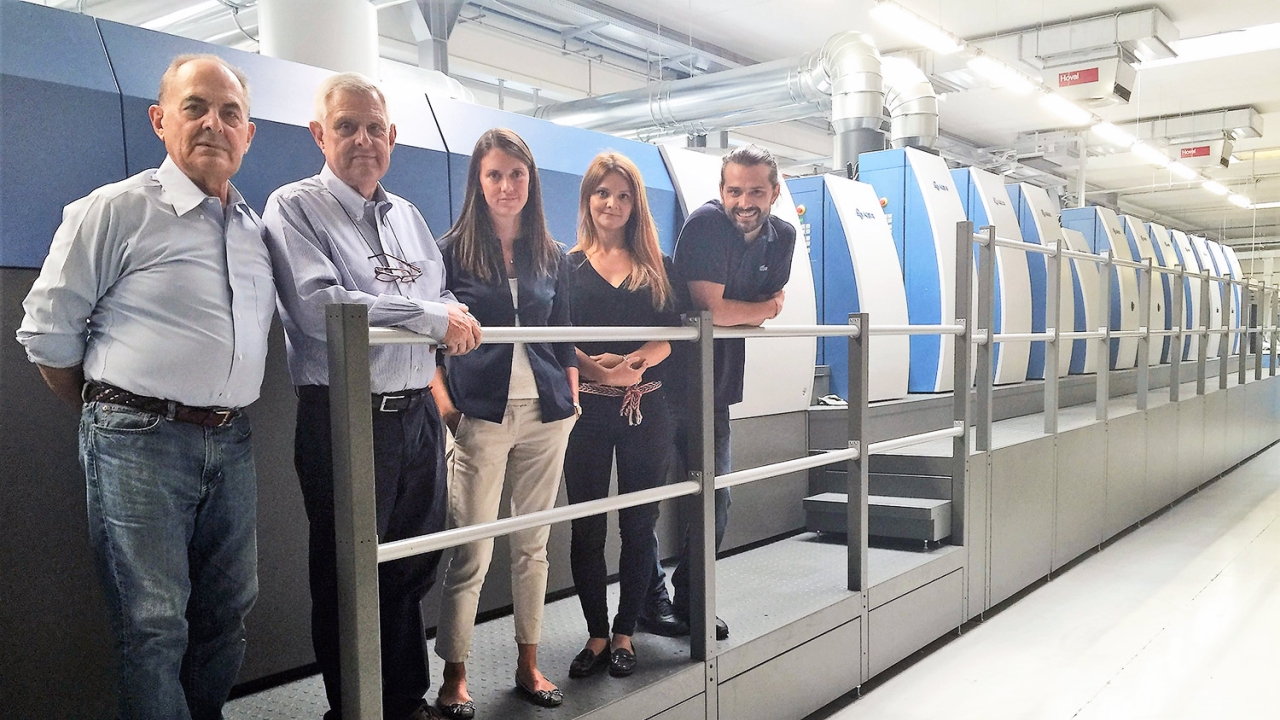

Arca-Box of Palazzolo, Italy has invested a 7-color KBA Rapida 106 for the production of luxury packaging.

The press is equipped for UV production, and is configured with a coater tower, two interdeck dryers and another coater in front of the three-fold delivery extension. Further features include in-line ink metering, QualiTronic ColorControl, and DensiTronic Professional for densitometric and spectral metering of the printed image. The special configuration with printing unit after the coater, referred to as ‘Plus One’, is described by KBA as particularly practical for producing high quality luxury packaging.

Arca-Box designs and produces high quality presentation packaging made of plastic film and cardboard. It has previously acquired a 5-color KBA Rapida 105 with coater and equipment for cardboard and film printing in 2000, which was fitted with six interdeck dryers for UV printing and three UV lamps in the delivery extension.

Besides traditional packaging production, the new Rapida is also to be used for printing on plastic, plus ‘automatic’ packaging, containers, displays, tapes, clipstrips and more.

Aldo and Gaetano Gasparini, the owners of Arca-Box, had been looking at investing in a new sheet-fed offset press for a number of years to complement the Rapid 105, and an even older Rapida 104. This resulted in the investment in the extra-long medium-format Rapida with 12 printing and finishing units.

Arca-Box's main aim is to produce packaging products that allow its customers to beat their competition at point of sale, so it invests in advanced techniques and technology, coupled with forming strategic partnerships and offering packaging development, graphic design and prototyping.

The Rapida 106 has already greatly enhanced productivity at Arca-Box in its first few months of operation, and demonstrated a high degree of versatility with extensive in-line finishing options, exceeding by far the expectations of the Arco-Box management.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.