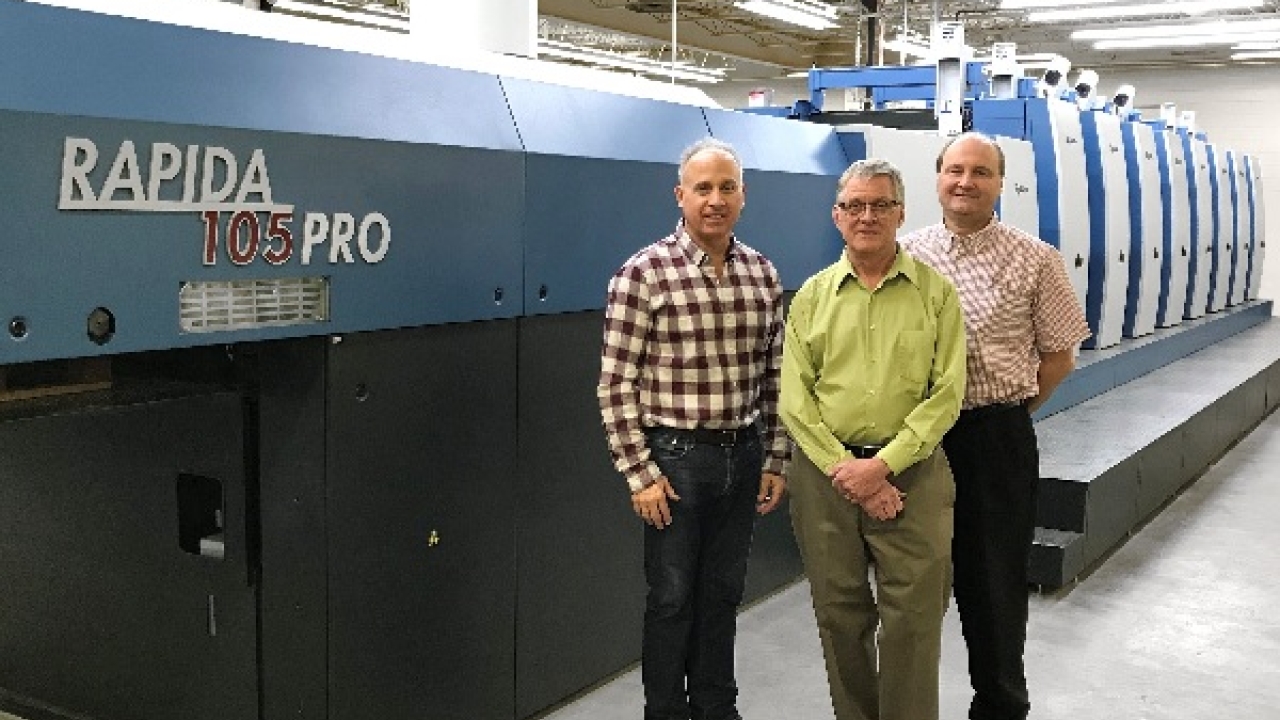

Oak Printing expands capacity with Koenig & Bauer Rapida 105 PRO

Oak Printing, a nearly 100-year-old manufacturer of paper labels, took delivery this fall of a new Koenig & Bauer Rapida 105 PRO 41-inch eight-color press at its 55,000-sq-ft facility in Strongsville, Ohio, just south of Cleveland.

‘We produce labels for well-known brands in the country as well as some specialized start-ups,’ said Michael Kisha, Oak’s vice president of manufacturing. ‘Our labels can be found on millions of paint cans from leading manufacturers as well as some of the country’s most popular breweries. What differentiates Oak Printing from our competitors is our willingness to go the extra mile for them. What do I mean by that? Take a craft beer manufacturer; they order from us very creative labels expressing their niche beer and expect their labels to communicate its uniqueness and be available when their beer is ready to be bottled. We have to be ready to do whatever it takes to assure they get their beer out to consumers on time. Our motto is to always serve the customer.’

With older offset presses on its production floor, Oak Printing was seeking to capitalize on the latest unique automated technology in the market. After spending a year and a half researching presses—both used and new---and logging nearly 25,000 air miles for various demos and meetings, Kisha made the decision to partner with KBA.

The Rapida 105 PRO being installed at Oak Printing is equipped with a host of automated Koenig & Bauer technology that can handle a variety of substrates. Oak Printing primarily uses C1S (coated one side) sheets up to 60-70 lbs for its paint can labels and WS material as light as 40 lbs for its craft beer customers.

Oak Printing will be able to double its capacity with the new Koenig & Bauer Rapida 105 PRO and continue to grow, possibly to move into new markets.

‘What really excited our entire team including our press operators is the integrated quality control camera feature on press. This automated system lends itself to getting up to color faster and maintaining color consistency all across the sheet. That’s very important to our customers, many of whom are in the color business. All of our labels have to be consistent across a home center store shelf, grocery aisle, or bar.’

In the meantime, Oak will be running the new Koenig & Bauer press as its key workhorse press. ‘Our labels need to capture a consumer’s attention,’ Kisha said. ‘Designers, especially for the craft brews, are incorporating unusual and surprising designs and images, contrasting colors, decorative and inventive artwork. This new Koenig & Bauer press will enable us to produce those labels faster, more efficiently, and more productively. It’s an exciting time to work at Oak Printing.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.