Propack installs first Newfoil Servo in the Middle East

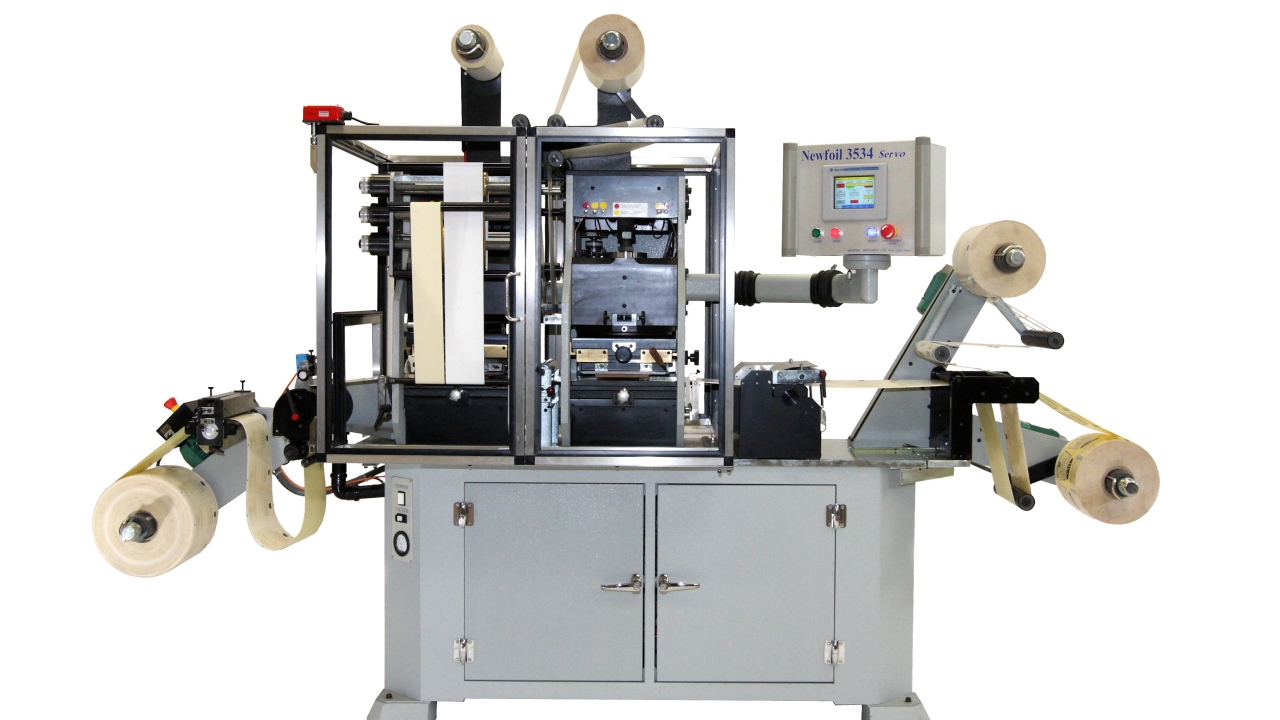

Propack Labelling Solutions, a printing company based in Halat, Lebanon, has installed a Newfoil 3534, the first model from the Newfoil Servo range of hot foil stamping and converting machines installed in the Middle East.

The Newfoil Servo range combines the latest developments in motion control servo technology with Newfoil’s build quality. The range also uses an intuitive touchscreen for control and diagnostic purposes.

The Newfoil Servo is able to store settings for repeat jobs. This not only reduces operator input and set-up time but also produces less waste. A simple changeover typically takes 5-10 minutes and the machine can reach speeds up to 18,000 impressions an hour.

Propack’s investment in a Newfoil 3534 complements its Mark Andy 8-color P5 Series flexo press. By utilizing the Newfoil 3534’s hot foil stamping ability and new Quick Set embossing unit, Propack is able to produce high quality labels for the Middle Eastern market.

Although the Newfoil 3534 installed at Propack includes one flat bed hot stamping/embossing station and one die-cutting/embossing station, the modular design means that the machine is available in various configurations.

The 3534 model has a maximum web width of 340mm, which is ideally suited to today’s digital converting market, according to Newfoil, with other web widths available.

Other options for the Servo include an in-line flexo unit, in-line flat screen printing unit, lamination, hologram registration system, Quick Set embossing unit, digital re-registration for pre-printed materials, web slitting, sheeting and stacking systems, and in-line variable data printing.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.