Zecher invests in LaserEcoClean

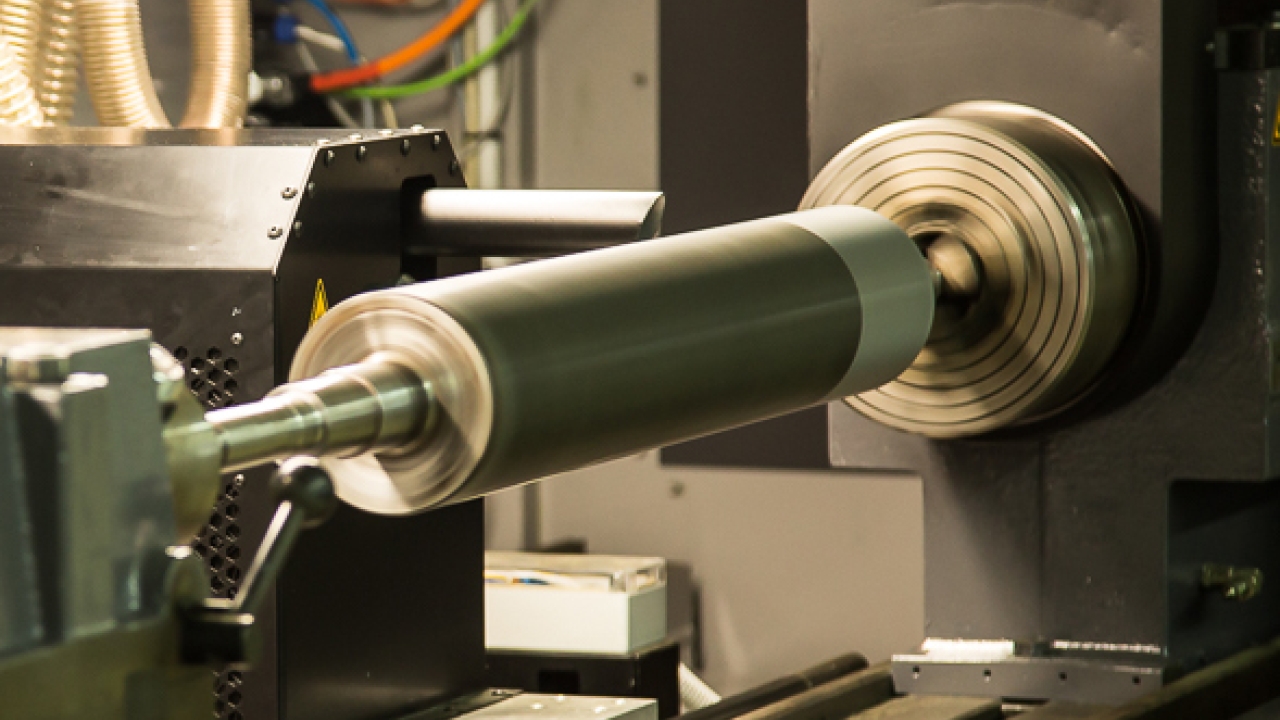

Anilox roll manufacturer Zecher has invested in LaserEcoClean laser cleaning technology to facilitate regular deep cleaning of operational anilox rollers.

This, the company said, is ‘of crucial importance when it comes to high-quality printing’. It commented that conventional procedures remove only part of the accumulated residues concerned.

Jörg Rohde, head of applications technology at Zecher, said: ‘Microscopic imaging reveals that the inner recesses of the cells on cleaned rollers are barely distinguishable from those of a brand-new roller. After the cleaning process, the pick-up volume of the anilox roller can once again be used to its full extent, and printers benefit from the same uniform inking performance as before.’

Zecher is an international manufacturer of chrome and ceramic anilox rollers, with 65-plus years of experience in the manufacture of anilox rollers. Zecher produces more than 12,000 engraved anilox rollers annually at its main plant in the German town of Paderborn. The laser cleaning system has been installed in Paderborn, and expands the portfolio of cleaning services offered by Zecher.

‘As a relatively low-power laser beam is used, the temperature of the ceramic surface is well below the material’s melting point, which prevents any damage to the outside of the anilox roller,’ continued Rohde.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.