Asahi Photoproducts introduces new medium hard AFP-TSP plate for paper-based printing

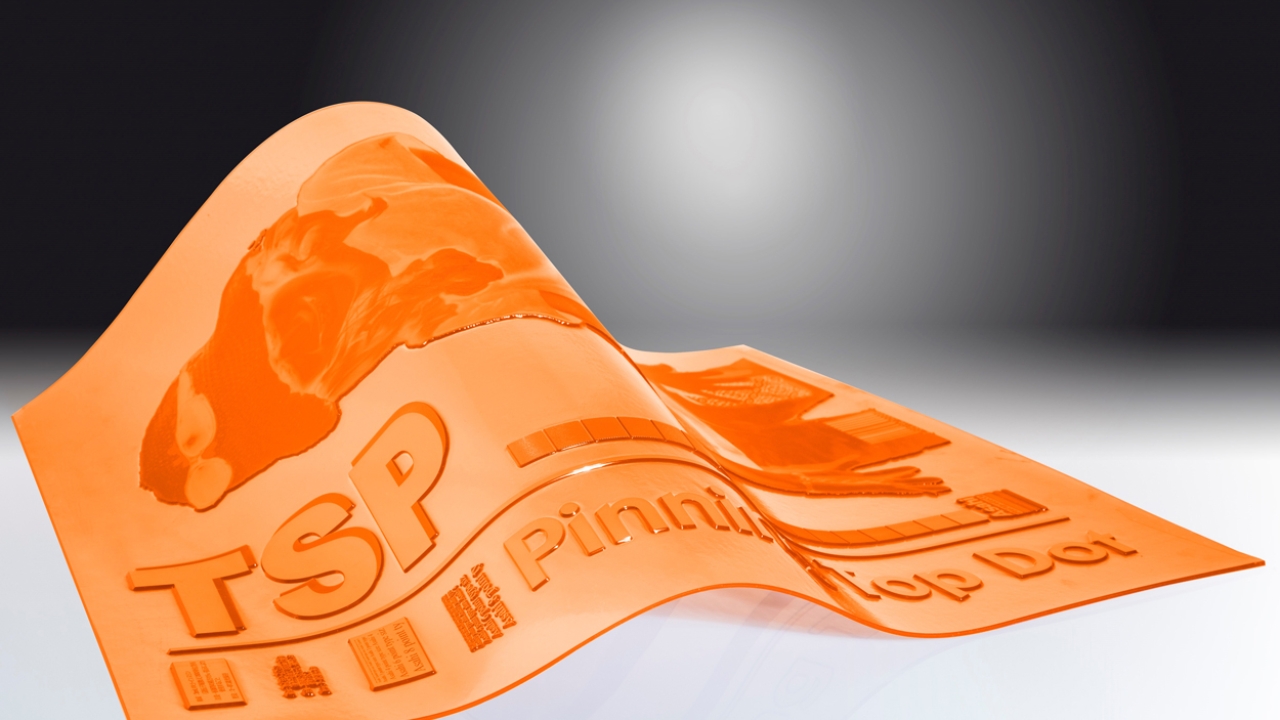

Asahi Photoproducts has introduced AFP-TSP, a new medium hard plate in its pinning top dot (PTD) technology family designed for paper, folding carton and corrugated board applications, as well as for all flexible packaging such as aluminum or film substrates.

PTD technology facilitates clean ink transfer and prevents ink accumulating on the plate surface and on shoulders in screen areas, meaning fewer stoppages for plate cleaning, reduced press downtime and improved machine overall equipment effectiveness.

AFP-TSP (top soft pinning) plates allow a kiss-touch pressure setting, thus extending plate life and further reducing downtime and increasing margins.

The new medium hard plate comes in four thicknesses with Shore A hardness ranging from 48 to 69, and complements the harder AFP-TOP plates launched last year. AFP-TSP plates are tailor-made for paper and higher quality corrugated board applications with water-based inks. They are also compatible with solvent and most UV-curable inks, enabling all converters to benefit from PTD technology.

All four plates in the AFP-TSP series offer a resolution of 175lpi. The plate thicknesses available are 1.14mm (Shore A hardness 69), 1.7mm (Shore A 58), 2.54mm (Shore A 49) and 2.84mm (Shore A 48). They are also compatible with the latest screening and micro-cell technologies.

Further, AFP-TSP plates have a more malleable structure than other flexo plates, giving them superb limpness that significantly reduces plate lift, especially with applications on small cylinders such as pre-printing belt machines. Plate lift can cause plate damage and print defects, and is remedied only by stopping the press. A strong base lamination provides plate stability in difficult printing conditions while the printing surface has good abrasion-resistance properties, extending the life of the plate.

A specially engineered Asahi polymer chemistry creates a low plate surface tension, which causes ink to form a globule and remain on the dot without running down the shoulders. This creates a higher ink profile with a large contact angle and high pinning point that delivers cleaner ink transfer from plate to substrate.

AFP-TSP also facilitates homogeneous ink transfer in solid and line work, and better control of ink trapping when different colour inks are printed on top of each other.

‘The new plate perfectly complements the harder AFP-TOP plate for high quality screen work within one job,’ said Dr. Dieter Niederstadt, technical marketing manager at Asahi Photoproducts Europe. ‘AFP-TSP and the harder AFP-TOP provide the perfect solution that can encourage brand owners and retail chains to transfer their work from other printing technologies to flexography.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.