EyeC launches quality control inspection for cigarette and tobacco packaging

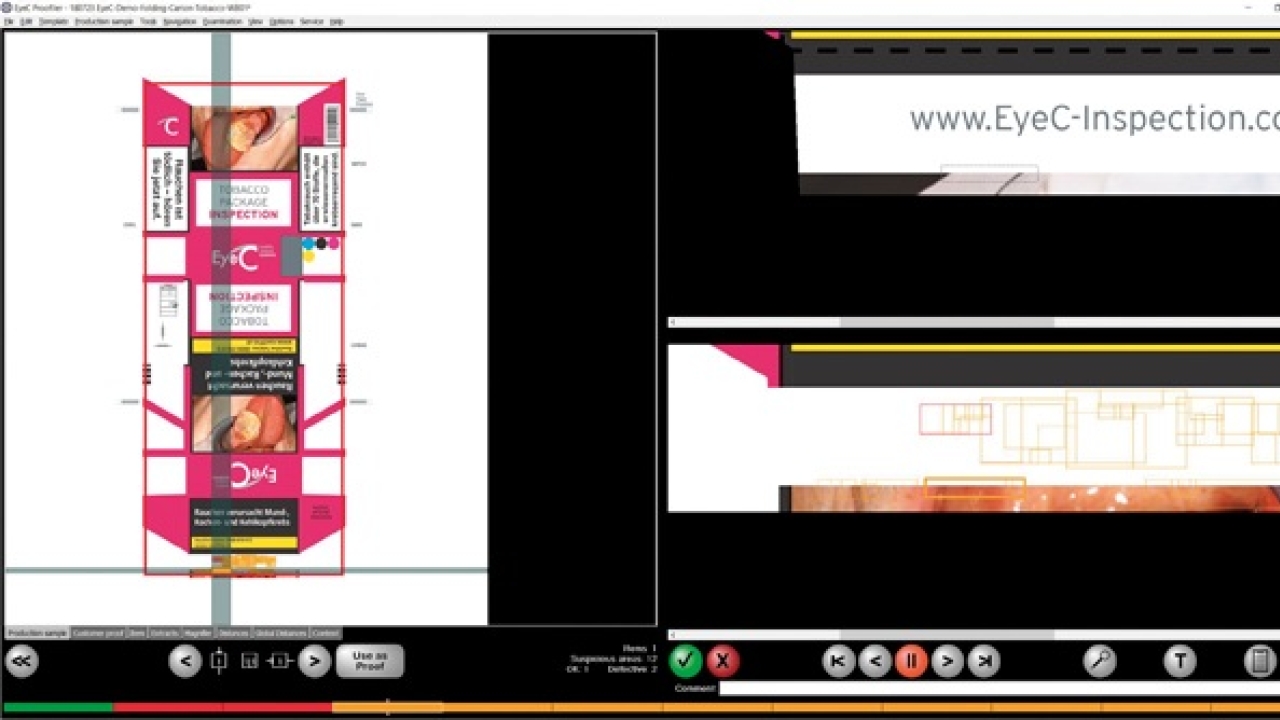

EyeC, manufacturer of print inspection systems, has launched new inspection systems for a quick and automated inspection of cigarette and tobacco packs.

Strict regulations on cigarette and tobacco packaging has been forcing manufacturers to strengthen their quality controls. One of their main challenges is to ensure the quality and conformity of health warnings. With EyeC inspection systems, they can now perform quality checks at each of the production stages easily and make sure that their cigarette and tobacco packs are in full compliance with legal requirements.

One of the key components of EyeC’s new system is the EyeC health warning inspection tool. Using the EyeC HWIT, users quickly and easily create a merged file that contains all compliant health warnings and will serve as a reference during inspections. The main advantage of this software, is that it enables users to assign and combine health warnings coming directly from health warning document libraries — such as general warnings, additional warnings, and side information messages — to their artwork files automatically.

With the help of this secured reference file and EyeC inspection systems, users can perform a comprehensive inspection. At pre-press, they can use the EyeC Proofiler Graphic to check print files (one-up or step-and-repeat files) automatically. During and after printing, they can use the EyeC Proofiler to control printed samples quickly. EyeC systems detect all items automatically and inspect the complete content of files or printed samples. Text, graphics, 1D and 2D codes as well as health warnings and their rotations are checked in a single inspection cycle. All deviations are displayed clearly, so that users detect any quality issues immediately.

‘With the EyeC inspection systems and the EyeC HWIT, tobacco manufacturers can now easily automate their controls and avoid product recalls. They no longer have to perform tedious and complicated manual check of health warnings,‘ says Oliver Peitzner, product manager EyeC Proofiler. ‘Our first product demonstrations have been a real success. The need of automation and risk reduction has never been so high in the tobacco industry.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.