Flex Films develops Flexpet F-STF BOPET film

Flex Films, the global film manufacturing arm of Uflex, has developed Flexpet F-STF, a biaxially oriented polyethylene terephthalate (BOPET) film with a velvety surface.

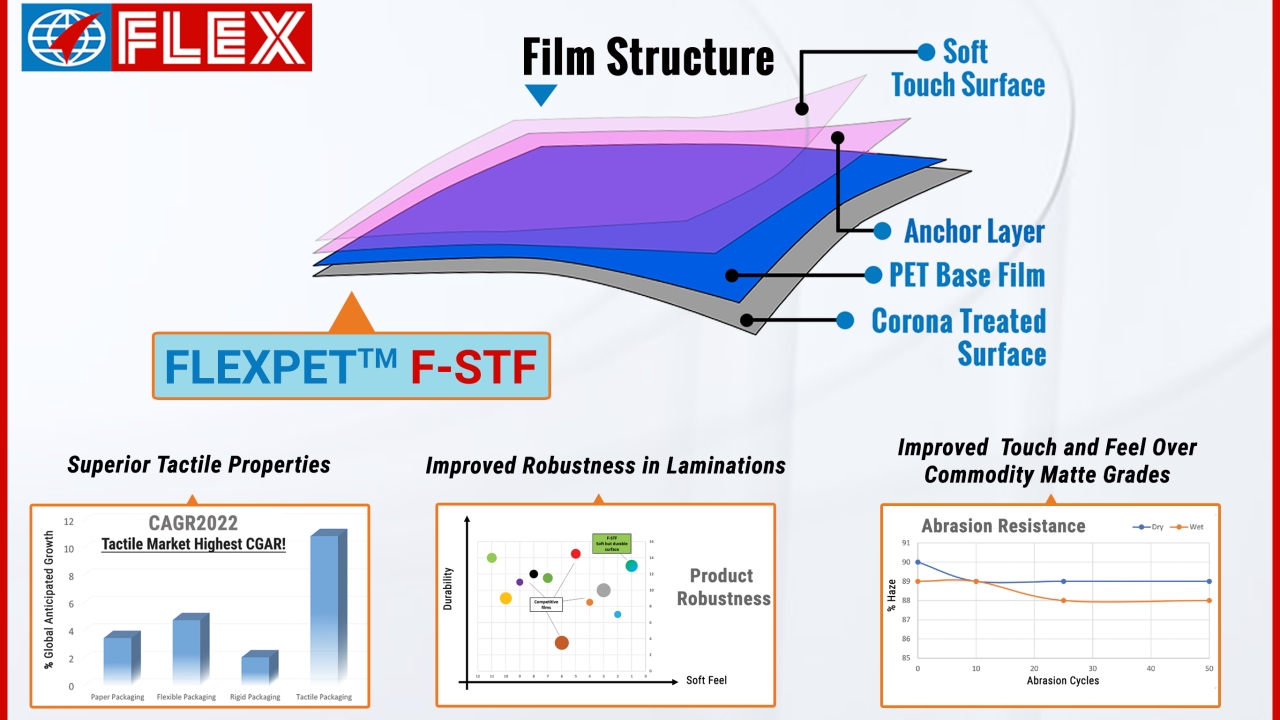

Flexpet F-STF has been developed at the Flex Films manufacturing plant in the US. Dr Steven J. Sargeant, general manager of technology at Flex Films USA, said: ‘If we scratch the surface of this film, it won’t be scratched. Soft touch is rendered through a robust surface coating, in combination with a proprietary in-line anchor coating on the base polyester film. It is this combination which imparts unique properties of self-healing, toughness and durability along with the soft texture. This effectively increases converters’ yield as they generate less scrap and have less customer rejections or other associated issues.’

Vijay Yadav, business head at Flex Films, USA, added: ‘The film has superior tactile properties. In addition to a soft surface that is heat and water resistant, the film exhibits improved scuff resistance along with ultra-low gloss and robustness superior to commodity matte surface films. All polymeric films tend to stick to themselves which is termed as blocking. This isn’t an issue with our soft touch film. Through the combination of base film and off-line coating design, we have been able to avoid blocking, improve durability of the soft touch at high processing speeds. This in turn leads to higher production throughput. The film is thinner than many others currently available in the market, thus, decreasing material costs of packaging at brands’ end.’

Anantshree Chaturvedi, vice chairman and CEO at Flex Films International, said: ‘This film is FDA compliant for a range of uses making it further unique. It finds extensive use in luxury brand packaging, decorative packaging, labeling, graphic advertising banners, and high-end stationery products among others. F-STF film exhibits low gloss, excellent matte homogeneity with high haze of more than 90 percent, and very high contact clarity. This means that the film can be readily reverse printed by convertors to impart deep and rich graphics. The surface maintains its soft and luxurious feel yet is strong and durable enough to withstand the ensuing rigors of handling throughout the value chain. Tactile feel products have an anticipated CAGR of 12-15 percent and are thought to be the highest growth segment in flexible packaging spaces in the US. This is an encouraging opportunity that Flex Films is pursuing.’

Ashok Chaturvedi, Uflex chairman and managing director, concluded: ‘This is a classic example of value engineering. My engineers at Flex Films have addressed two rather dichotomous issues of maintaining a velvety soft surface texture of the BOPET film while simultaneously ensuring good tensile strength. This is one of the very many ways we keep enhancing business value for our clients globally.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.