GEW launches air-cooled UV LED curing system

GEW (EC) has taken LED curing one step further by introducing a fully air-cooled UV LED lamphead.

Since their inception, UV LEDs have been overcoming a number of technical and economic obstacles that prevented commercial acceptance. Relatively high initial cost and limited availability of LED inks were the main barriers that prevented their general adoption across the industry

The barriers to adoption have now been lowered further. After an intense development period GEW have now introduced the new, fully air-cooled UV LED curing system lamphead LA1. Special consideration was given to the enhanced airflow design to ensure effective heat dissipation at high power levels. The LA1 is built around the same proven cassette-based design as the E2C and LW1 lampheads and is fully compatible with existing ArcLED systems without the need for external chillers, pipes or coolant or indeed any other modification.

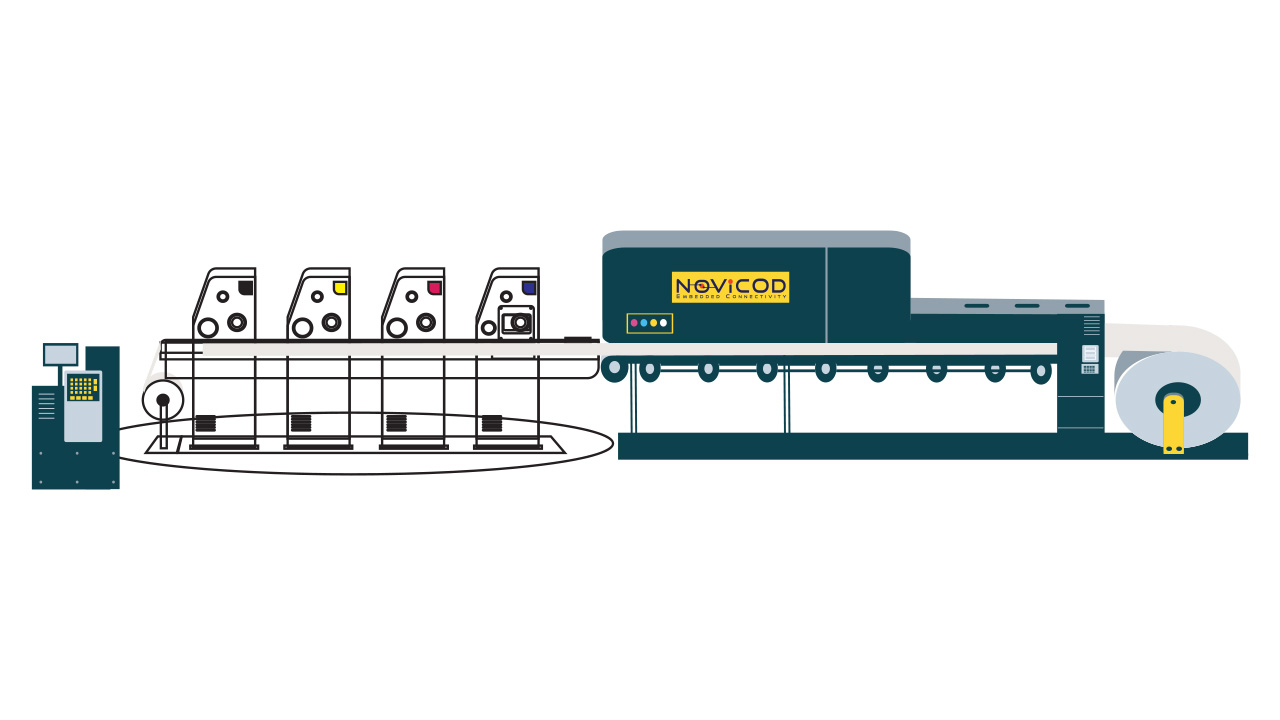

Within an ArcLED system, printers are able to operate full hybrid UV curing, working with both mercury arc and LED lamp technology on the same press. Mercury arc cassettes and LED cassettes both use the same lamphead casing, the same power supply and the same air cooling ducts. The operator swaps the required cassette and the RHINO ArcLED power supply automatically recognizes which type of cassette is installed in the machine, switches from low voltage DC power for the LEDs to high voltage AC for the arc lamps and changes the display on the RHINO touch screen control accordingly.

The LA1 is an UV LED curing product that is able to perform without the heavy infrastructure and maintenance required by water-cooled LEDs while enjoying the benefits of the efficiency, reliability and extended life cycles of LEDs.

The RHINO ArcLED power supply is extremely energy efficient showing considerable energy savings when compared to conventional electronic power supplies. ArcLED gives the possibility to run a truly flexible hybrid curing system. Several printers have already doubled the productivity of their machines by optimizing curing to best suit each process on their presses.

The ArcLED UV curing system allows for upgradeability of arc lamp to UV LED systems. Printing presses that operate with ArcLED technology can now be upgraded from arc lamps to LED to fully exploit the advantages of both technologies with the same power supply, controls and cooling system. This will give the user maximum freedom and flexibility and will avoid getting locked in to one type of curing technology.

GEW RHINO ArcLED curing systems are supplied, as standard, with GEW’s Embedded Service package which allows remote monitoring of the system running condition, allowing the manufacturer’s service engineers to detect and correct out of tolerance parameters. This type of remote preventive maintenance ensures the entire UV system operates at peak performance at all times thus avoiding unplanned machine stoppages.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.