Multinational installs third KPG tube press in 18 months

- Presses installed at different locations, and operating round-the-clock

- Fitted with Martin Automatic butt splicer, and automatic transfer rewinder

A global producer of personal and home care products has recently installed its third KPG Euroflex tube press for printing tube barrier laminates.

The three presses are installed at different locations, and the printed laminates are formed into tubes for a range of oral care products. They are fully automatic and operate 24 hours a day.

Both 260mm and 400mm Euroflex presses have been installed. The former is specified with six UV flexo color units on a steel chilled 1,000mm diameter central impression (CI) drum, plus varnish with a rotary screen unit providing an additional color.

Euroflex 400

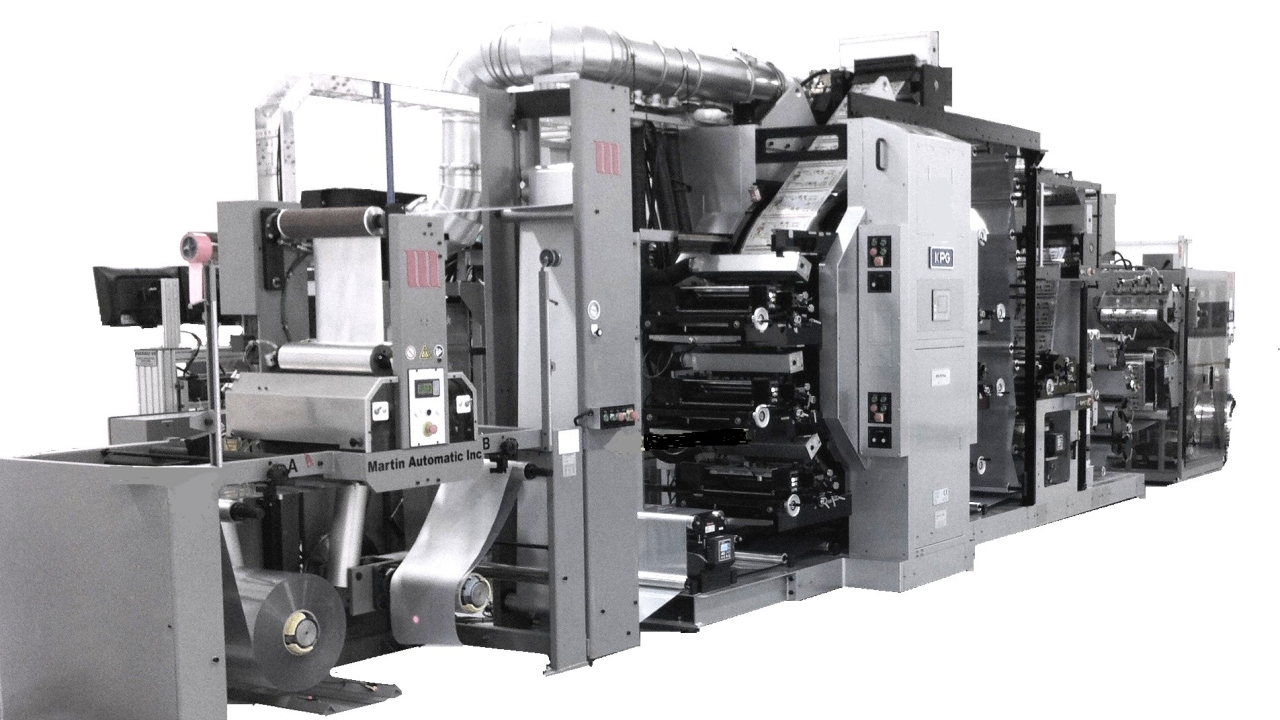

The Euroflex 400 (pictured, top) utilises a 1,800mm diameter CI drum with seven colors, with the potential to fit an eighth print unit at a later date. A flexo varnish module is adjacent to the CI drum and the press design allows for a rotary screen unit to be fitted to meet future production requirements.

For non-stop production, both versions are fitted with a Martin Automatic butt splicer, and automatic transfer rewinder. With an integrated slitter, the web can be split into four ribbons.

As well as ABL and PBL laminates, the Euroflex tube press can be used for printing films, and with the addition of a rotary die cutting unit and waste rewind is suitable for label production.

Robust construction

Built from cast iron, with a 150mm base and 100mm side frames, KPG said the construction of the Euroflex tube press virtually eliminates vibration, even when operating at speeds of up to 100m/min.

The Euroflex is also fitted with a servo controlled expansion roller for use with ABL materials and an elongated web path ensures efficient flow-out of varnish.

Other features include AC servo in-feed/out-feed, corona treater and web cleaner, two chill rollers with chiller unit, BST web guiding system and GEW UV curing system.

Read more on printing tubes here

Read more on CI press technology here

Read more on substrates here

Read more on press technology here

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.