Digital: a brand owner’s perspective

Digital printing has been on the market for a while: more than 15 years ago, I introduced it on a premium personal care range through digitally printed self-adhesive labels. This covered a range of different flavors, several packaging formats and small quantities of each, making it ideal for digital printing, which at that time was a new technology.

As a new technology, digital label printing was considered too slow and too expensive. Many critics also claimed that digital printing was of a lesser quality. The latter was not the case and the toiletries range proved its success with the digitally printed labels.

At Mondelēz International, the biggest confectionary company in the world, we have implemented digital printing on cartonboard for many years. Consumers order their personalized products online via Cadbury Gifts Direct (www.cadburygiftsdirect.co.uk) or our premium range Green & Black’s Gifts Direct (www.greenandblacksdirect.com).

Mondelēz International values its brands highly, so matching brand colors is important to us. This is a challenge but it can be achieved, with a spot color able to be developed in some cases. For packaging developers, obtaining the same color when using different material types is another challenge. How many times have I noticed cap and bottle mismatched? Brand colors on different substrates vary most of the time, produced using different printing technologies or printed in different regions across the globe. The consumer usually does not notice the discrepancies, but brand owners and their team do. Other challenges with digital include the ‘no-label’ look and printing on corrugated board, depending on whether you print on brown or white board. Ink coverage and matches with conventional printing is important for shelf appearance.

Improvements

Digital printing technology continues to grow and expand, however. Many converters have installed digital printing machines, as have co-packers. The machine builders have improved width, speed and cost.

Improvements on opacity, coverage, colors and add-on equipment, such as coaters and laminators, have also been made. This has seen partnerships develop with machine manufacturers along with digital printing companies working together. Raw material suppliers, substrate specialists, coatings and adhesives companies have become involved.

Digital printing on flexible materials has been a more recent development, as sleeves and labels should not be considered as flexible material. Surface printing or reverse printing, depending if you have mono, duplex or even triplex substrates, make this possible, although not all digital printers can print digitally on flexible substrates.

From in-mold labels and aluminum foil, to hot and cold seal applications, digital printing can be introduced on any commodity. Cold seal is a challenge, especially if you would like to do some overprinting or need cold seal application after printing the material.

Selection of the right converter is quite important. It is not only the digital printer selection, but also the add-on machinery they have available. Cut, crease, glue for cartons or lamination; cover varnish, and slitting for flexibles.

And although materials such as labels, sleeves, corrugated board and cartonboard are not necessarily in direct contact with food, due diligence for food compliances, taint andodor, and all relevant tests are crucial. It is the brand owner’s responsibility to have the food

compliances in place. For food compliance, offset must be considered. Once the flexible material is on reel, the surface print is in contact with the inside of the material. Food compliance is OK if you have a sufficient barrier in regard of migration. In the end, it is again the brand’s responsibility to perform due diligence and provide the complete documentation and execute the necessary tests. This is of course not only for digital printing, but is a general rule for any packaging development and launching any product on the market.

I have been leading the introduction of digital printing technology, cross category and globally, with the technology now smoothly rolling out into various categories and different regions. A current activation is Tang, our biggest drink brand in Brazil.

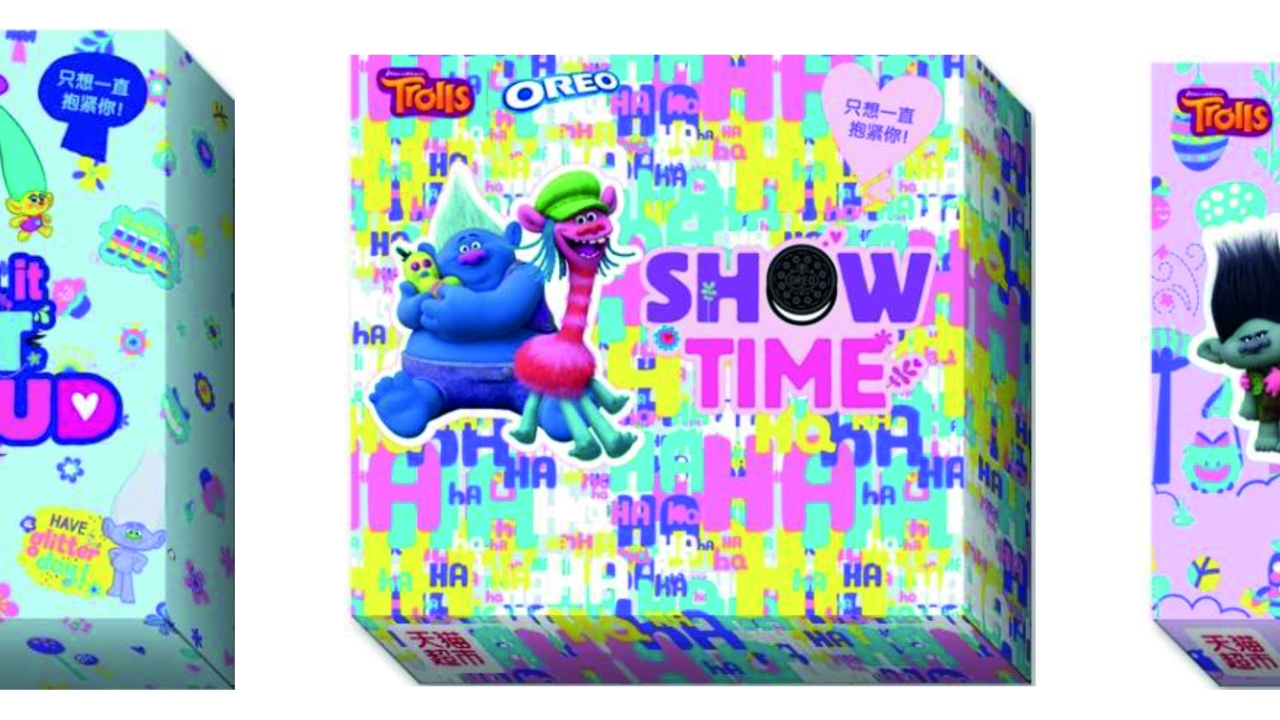

Digital printing is a growing business, for sure. Whatever the technology or specialization of the machine manufacturers, new and improved applications are coming to market almost every week. The quality is matching conventional printing or even bettering it. And it is no longer small quantities or short runs, as Mondelēz International has proved with Oreo and Tang.

This opinion can be read in L&L issue 4, 2017, and here

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.