How much are your aniloxes costing you?

Whether printing on labels, film and carton or corrugated, the demands on flexo printers to achieve the closest possible color match by their customers to the approved proof is ever increasing.

The higher demand for color accuracy the more effort the printer must make to achieve that demand. The errors in colors, or the delta E between the print and proof, is measured with a densitometer and is used to:

- Determine the color difference of the print or proof from the original

- Determine how much the color has drifted during the print run

- Remove density subjectivity (as much as possible)

To achieve the demands of accurate color, the operators typically stop the press to take a sample (a pull) of the job to determine if each color is accurate.

Logically this should be a relatively simple and quick task; after all we know the substrate that is being printed on, the ink kitchen has carried out all their checks and have delivered ink of the correct density and viscosity for the job.

Yet for some reason it often proves necessary to run the press to take a pull to check for density accuracy, then adjust the ink, four, five or more times before the job is color correct. This ink adjusting to achieve color accuracy can result in many hundreds of meters of expensive material being wasted, and absorbs valuable production time.

Many printers and converters have found over the past decade that by managing their anilox inventory they are achieving the color density much quicker, reducing the number of pulls required, which has increased their ability to be more productive and logically reduced the waste produced.

How much are your Aniloxes costing you?

Anilox manufacturers will often supply a banded roll to determine the best ink carrying capacity or volume on the aniloxes to be used. A very small difference in anilox volume can give a very discernible difference in density, hence color when printing. From various print trials, it has been determined that a difference of 0.4 cm³/m² for process colors, on an anilox will give approximately 3deltaE difference on print. Naturally there are many variables here, the ink type, the substrate press, running speeds etc., but it has proven to be a good and reliable guide over the past 10 years.

A minor change in anilox volume will make a big color shift.

0.4 cm³/m² ~3deltaE

If the aniloxes were known to be within a close ink carrying capacity of each other and also laterally, then the job set-up time on press will be reduced and the waste run off material would also be reduced. The ink carrying capacity, the volume, for each anilox is a vital component of each anilox.

Using four process aniloxes as an example, if all four process aniloxes are within 0.4 cm³/m² of the 3.4 cm³/m² stated by the anilox engraver when it was new, we will know there is a very good chance of setting up the press within two to four pulls.

The aniloxes were measured with an AniCAM with Anilox QC, which evolved from the demands from the major packaging converters for an anilox measurement device with inventory management with the following requirements:

- Accuracy: of ±0.1 cm³/m² for process aniloxes

- Repeatable measurements of ±0.1 cm³/m² when measured on the same place

- Inter-operability: the ability for different operators to get the same readings

- Ease of use with data archiving for anilox inventory management

- No time, or minimal time, lost in production due to measurement times

- Measurement differences between the devices to be minimal

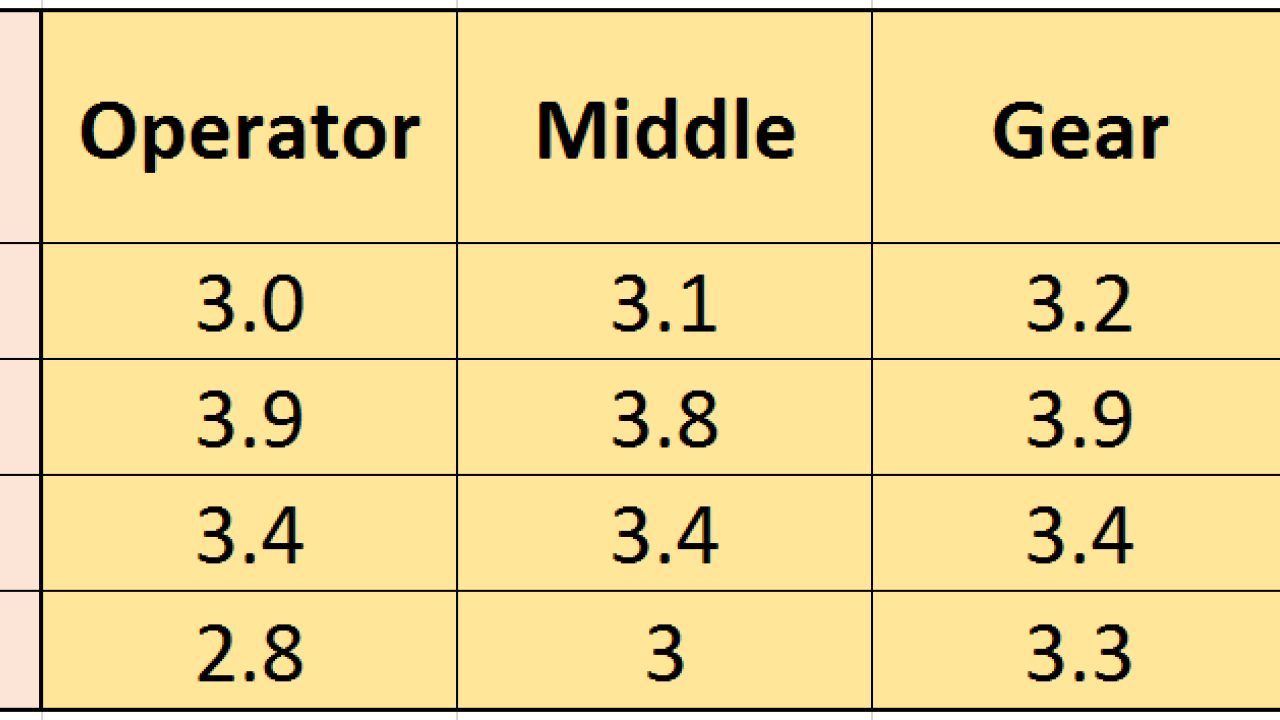

For the examples in this article the aniloxes were measured laterally along the anilox, on the left (operator), middle and right (gear) points, however for wide aniloxes it is not uncommon to measure in five places across the anilox.

It is important to recognize that the AniCAM with Anilox QC is particularly accurate in its measurement of volume measurement. This mathematically proven accuracy was proven thanks to the work carried out by Dr Davide Deganello at Swansea university, Welsh Centre for Printing and Coating (WCPC) in 2007. WCPC, under the leadership of Professor Tim Claypole is one of the leading print universities in Europe.

Measurements on Anilox 1 shows three reading of 3.0; 3.1; 3.2 cm³/m², giving an average reading of 3.1 cm³/m² and a variation across the roll of 0.2 cm³/m². The variation across the roll and the difference from the desired 3.4 cm³/m² is within 0.3 volume, so is good for use.

Anilox 2 readings are 3.9; 3.8; 3.9 cm³/m² giving an average reading of 3.9 (to 1 decimal point); with a difference across the roll of 0.1 cm³/m². With the volume being measured at 0.5 cm³/m² above the stated volume we see a typical example of where time is needed to reduce the ink on press to achieve the correct color density.

This anilox, which may have been marked up with the lower 3.4 volume in error, or has been measured using an inaccurate method of measurement, should be rejected and returned to the manufacturer for re-engraving to an accurate 3.4 cm³/m² if time and waste is to be saved on press.

Anilox 3 readings are all at 3.4, this is a perfect anilox and is clearly fine to use on the press.

Anilox 4: Shows three reading of 2.8; 3.0; 3.3 cm³/m². Showing an average reading of 3.0 which would normally be fine but the difference across the roll 0.5 cm³/m² which is beyond the acceptable limit and the anilox needs to be returned for refurbishment.

Therefore, clearly anilox 2 and 4 should not be used on-press and should be sent for refurbishing if set-up time is to be reduced and many hundreds of meters of waste material is to be saved.

Conclusion

Typically, once users have got their aniloxes inventory managed and have had ‘out of specification’ aniloxes refurbished, we get feedback that most printers are able to benefit from at minimum improvement of one hour additional production time per press per day, and a minimum of 15 percent reduction in set up waste.

How much your aniloxes are costing you? We get regular feedback on the savings made from the 500 plus sites using the Anilox QC with AniCAM for anilox inventory management. The savings are reasonably uniform in all countries; for sites with three presses the savings typically vary from 300,000 EUR/330,000 USD to 500,000 EUR/550,000 USD a year. It’s certainly worth doing the calculation to get an indication of the savings for your own company.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.