Korea looks to the future

The label and package printing industry in South Korea is similarly intriguing. Continuing to be dominated by conventional print processes – namely letterpress and gravure – the market is seen as conservative and considered. ‘Korea is a very different market, with lots of intermittent offset and letterpress technology,’ describes Mario Fanton, director, digital printing, Asia-Pacific at Domino.

‘It is a conservative, price-sensitive market,’ confirms Helmuth Munter, segment manager, label and package printing at Durst.

Korea is though witnessing growth in shorter runs, flexible packaging and variable data, alongside changes in the nature of the labels being produced, as exampled by Levi Paul Dow III, sales manager for Asia and Africa at Polyonics.

‘Labels are getting smaller and including more information,’ he explains. ‘So while the square meterage is roughly the same, more labels are being produced as they are smaller.’

Won-Cheul Kim, digital press team manager at Dilli, adds: ‘Label printers are looking for niche markets, such as flexible packaging. There are also efforts to make packaging more environmentally friendly. Such changes in environmental regulations covering labels in Korea are driving growth in shrink sleeves.’

Chong Se Park, publisher and editor of The Printing Industry News, the sole newspaper for the Korean printing industry, tells L&L that the label market is growing at a similar rate to the country’s economy, around three to four percent. This includes food labels, while labels for pharmaceuticals and logistic applications are seeing above market growth. The cosmetics market is big business too, with Korean cosmetics popular in China and across Southeast Asia.

Seoul-based converter Tomatec focuses on industrial roll labels. Its president, Seok Yong Jeon, says that with a lot of what is produced in Korea exported, a trade war between the US and China would be bad for the country’s economy. Components for cars are given as an example, which are exported to produce finished products that are then sold into international markets.

Digital

Mr Kim, Mr Park, Dow and Fanton spoke at K-Print 2018, where digital printing, notably inkjet, was a standout topic. Speaking directly to them and other suppliers exhibiting at the show, it’s evident that digital printing is set to become ever-more prominent in Korea as both the industry and technology develop.

From desktop machines from Kiaro! and more complex systems from Valloy (Duoblade F/S), Anytron (any-002/any-Jet) and TrojanLabel, to the Konica Minolta AccurioLabel 190 and other full-blown engines, digital was exhibited in multiple guises. Domino’s stand featured a 7-color N610i UV inkjet digital press, while Dilli was showing a Neo Picasso 350W2, configured with two whites for high opacity on films, then printing with CMYK. With a printing width of 330mm, the press is capable of 25m/min at 1200 DPI or 50m/min at 600 dpi. Double white is available on the entry-level Neo Picasso 230 model. Other inkjet technology on show included the InkTec Jetrix ILP-220 CMYK+W UV LED inkjet label printer. It has a maximum printing width of 220mm and printing speed of 60m/min (30m/min if using white). A Durst Tau 330 RSC was demonstrated on the stand the company shared with DdP Story, its local distributor. A Truepress Jet L350UV+ stood on Screen’s stand.

‘The market continues to change with greater emphasis being placed on digital,’ says Fanton. ‘Education is taking place, including pre-press for digital and the total cost of ownership. This is looking at the initial price to print, which is one thing, compared to producing a finished printed product, where sometimes three or four machines are required when using conventional technology. So while the initial cost with digital is higher, the overall cost is likely lower.’

Mr Park of The Printing Industry News notes that the market for digital printing has slowed recently with many companies waiting to see which direction the market and technology takes.

‘Digital is still very young in Korea,’ says Munther. ‘HP has been penetrating the market for a while, but it is a cautious market and they don’t just jump in.’

Despite this, he identifies Korea as a good market for inkjet and one of the best markets in Asia for Durst. He attributes this to the company’s partnership with DdP Story, which became a Durst distributor in late 2013. Within 12 months the South Korean territory accounted for seven Tau 330 installations. The total is now nearer 20, which includes 330 and 330 RSC models installed directly at DdP Story, along with a Tau 150.

‘Having a printer double up as our local representative might seem strange but means it knows the market and can prove the technology works day in, day out,’ says Munter. ‘It is a convincing and successful proposition. DdP Story can even print jobs if a customer’s press goes down.’

Samwoo P&S has installed the first Valloy Bizpress 13R in Korea. The machine is a 13in roll-to-roll single pass digital label printer powered by a Xerox CMYK toner engine. Samwoo P&S prints high quality labels and flexible tubes for the food and cosmetic markets. It chose the Bizpress 13R to produce various short run jobs like promotional wet-tissue labels and stickers. It plans to add a further two Bizpress 13R units to provide additional production capacity.

Further printers that have already invested in digital are Xeikon users Taepyungyang Grand (TPYG) and All New Digital (AND) Korea, and Tomatec, which includes an HP Indigo ws4500 among its press portfolio.

TPYG senior managing director Jong-Su Lee explains: ‘Runs are becoming smaller and smaller, so to grow we need digital printing capacity.’

While it has a newer Xeikon CX3 press, AND Korea operates an older Xeikon 3020 model as its only means of production. AND Korea CEO Young ho Hong says: ‘I chose Xeikon because of the cost and print quality, although having the lowest volume model means we have to run two shifts to put through the amount of work needed.’

‘Our Xeikon press is currently running at 50 percent capacity,’ says TPYG’s Mr Lee. ‘The other 50 percent is for the future.’

At TYPG, digital printing sits alongside two Mark Andy flexo presses and three Sanki intermittent rotary letterpress machines within its equipment portfolio.

It is a similar story at Tomatec, which has two Mark Andy P5 flexo presses, 5- and 7-color models, in addition to other, older equipment such as an Arsoma press.

‘Our digital press is not profitable enough to run on its own and is mainly used to produce short runs, samples and very urgent orders,’ says Mr Jeon. ‘Some small orders do go on to become big orders, which are run on our conventional presses.’

AND Korea, currently a digital-only printer, sees adding a conventional press as the next step in balancing its production. Offset is likely to be its process of choice.

‘Only having digital can make it difficult to maintain volumes and productivity,’ explains Mr Hong. ‘Even though the label market and digital printing in Korea is expanding, it’s still hard to make good profit.

‘With digital, we thought we could pick up more profitable jobs. The reality is different. We are being compared to conventional so struggle to win with a digital press.’

Conventional

As such, digital is not having it all its own way in Korea.

This is evidenced in the supply chain. Dilli, as an example, represents Soma’s flexo printing technology in the country. Pavel Fischer, area sales manager at Soma, was present on the Dilli stand at K-Print 2018 and notes how his company is seeing a move to flexo from gravure, the dominant technology used to print packaging in Korea.

Mr Lee at TPYG notes how government action to curtail the installation of new gravure presses is helping drive such changes. David Ho, general manager, Martin Automatic Asia Pacific, sees this as an opportunity for label printers.

‘Gravure printers are used to wider and faster technology. Narrower, slower presses are harder for them. In a way this puts label printers in a strong position, as they are more comfortable with flexo and offset printing, and finishing techniques such as silkscreen and cold/hot foil.’

Flexo is also replacing letterpress and offset in a number of instances. Junha Lee, managing director at converter Formtec, which runs a fleet of Comco presses, sees flexo as rising in prominence due to productivity, higher quality and stability.

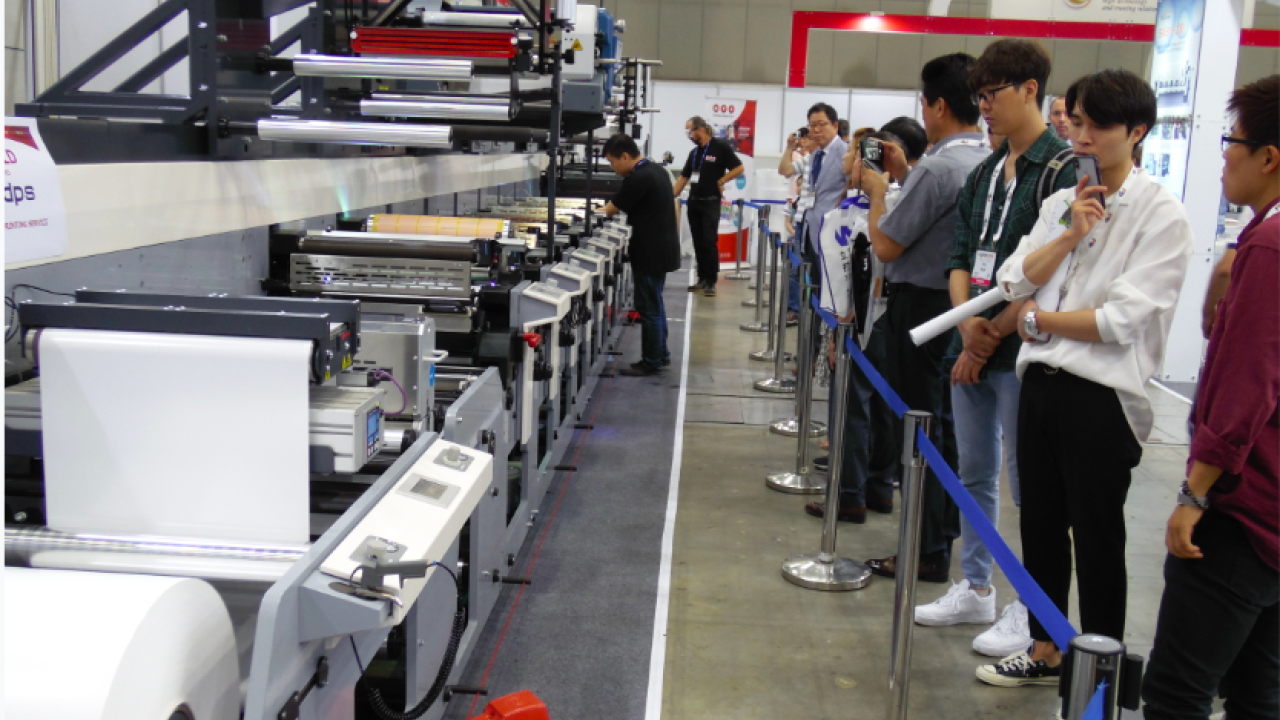

At K-Print 2018, conventional printing technology was evidenced by Sungsan, which had Wanjie WJLZ-350 and WJPS 350D machines on show; Bangsung and a BSR Plus 300; and M-Tech, with a ManiA-320 intermittent rotary letterpress label printing machine. The Sanki stand was a big draw, as it hosted an SOF-300 offset press and an MPS EF 530 flexo press. The latter featured eight color stations, a new UV LED system and a 520mm printing width.

Tim Klappe, managing director at MPS Systems Asia, says: ‘Flexo printing offers many advantages in label and film printing applications such as wraparound and shrink sleeves, and even flexible packaging. Compared to gravure printing, it’s a less expensive solution, especially for smaller and medium print runs with its capability of faster job changes.’

The MPS press was pre-sold to local printer DPS and is the first from the Dutch manufacturer into Korea. The company’s CEO Soon Suk Lee notes that the addition of the first MPS press in the country makes his company a pioneer. ‘We mostly use letterpress technology from Japan, Germany and the US in Korea. I wanted to do something different, so chose a flexo press from a Dutch manufacturer.

‘Many people are thinking about flexo in Korea and we have chosen to invest in a wider machine than is typical.’ The MPS press will be used by DPS for short runs of labels and flexible packaging.

‘This press allows us to move into new markets. Having a wider and faster flexo press, and using UV LED, sets us apart.’

Fine Webtech Label Solution System has installed a number of Gallus EM 430 S machines in recent times. The Gallus EM 430/510 S is a modular platform combining flexographic and screen printing units. It can be used to produce self-adhesive and monofoil labels as well as a wide range of other products. Fine Webtech produces products for the household, personal care, cosmetics and industry market segments.

Sunghwan Jang, vice president at Fine Webtech, comments: ‘The Gallus machines have increased our productivity and flexibility, and enabled us to expand our range of substrates. With the Gallus machines, we are competitive and can offer our customers the highest quality with the shortest delivery times.’

Tomatec is looking to upgrade one of its older machines for a newer Gallus model, which will be part of an automation initiative at the converter.

‘Automation is a big trend,’ says Mr Jeon. ‘We are looking to add automation across our production. Matrix removal is currently done manually, but this will be automated.’

The future

With this and the fact that AND Korea is looking to add conventional printing, and DPS investigating adding digital printing, it’s easy to see how vibrant yet challenging the market in Korea is. Formtec is another printer looking to add digital, to target new business. Inkjet is on its agenda, with speed and quality to increase and the cost of ink to reduce. ‘There is a bright market for digital,’ says Formtec’s Mr Lee. ‘The digital printing market has increased, with growing demand for shorter runs.’

By product, TPYG is to look at flexible packaging and growing IML in the markets it serves, notably Korea’s milk industry. AND Korea sees offering additional packaging formats – carton and corrugated – in its future, with Mr Hong saying: ‘In the future, we can’t only offer labels. Diversification is needed to tackle the high level of competition and secure the future.’

Mr Jeon says: ‘The label market is growing; as a company we have regularly achieved year-on-year growth of 20 percent over the last 15 years. In the near future it will be nearer 15 percent as competition increases in the market.’

Munter concludes: ‘I’d love to have more markets like Korea, definitely.'

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.