Starts control

These leaders reported starting journeys of continuous improvement, but were troubled because their efforts stalled after a month or two. Their management teams hit a wall, grinding projected improvements to a stop and failing to achieve planned improvement due to the weight of changing priorities and resource constraints.

The desire by these leaders to implement improvement projects across their companies has never been greater. My friends told me their teams have serious problems managing improvement project priorities due to distractions from raw material supplier reschedules, employee attendance, internal process inconsistencies, and conflicting resource demands.

I explained that many business leaders have no problem starting projects. They all share the same problem: an inability to complete them. Complaints included a long list of projects and a lack of available resources to assign to the tasks. I acknowledged this as a common problem, and then told a story. I had just returned from a facility in Illinois where the need for focus on improvement is prevalent. The same with a facility in Missouri, Pennsylvania, Arizona and California. Pick any one and the situation is the same. I explained one facility had 37 improvement initiatives underway, not counting the 17 requests for IT to modify information reports from their ERP systems. In one example, the IT group complained that each week requests for report modifications were growing significantly. The new requests forced weekly reprioritizing and a growing backlog of requests. IT groups feel the stress of starting new projects more than many departments, as managers look for their ERP systems to provide solutions to many problems. The complaint in production departments, development departments and IT departments is always about not being allowed to finish actions before having to shift to another priority.

Prioritization

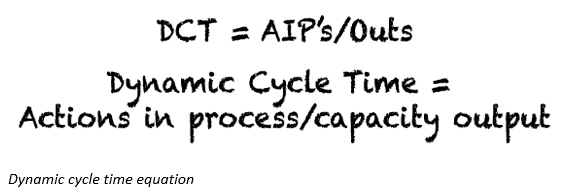

The art and science of prioritization are not new. In my executive coaching sessions, I ask the leadership teams to understand if time is of the essence, then time needs to be treated as a driving metric to performance. If we want to see projects completed in a timely fashion, we have to understand a straightforward mathematical approach to how many projects should start.

Most of the leaders remind me that they hate math, so I keep it simple. The dynamic cycle time (DCT) is a result of a collection of all the active improvement projects (AIPs) versus the resource set (capacity) defined to complete those projects. I ask the leaders to understand a couple of premises and insist they keep an open mind. First, project resources are not always finite. Second, if we can reduce the numerator (number of active projects) and hold the denominator (resource set) steady, we will see the cycle time of the project reduced. If we can consolidate resources by backlogging a project for later, we can take resources from the backlogged projects and dramatically improve the time to completion. The concept is not new, but many leaders lose sight of the discipline to control ‘starts’, not realizing the impact on the cycle time of the projects. The simple equation gets their attention.

Part of the issue is that the projects lack definition. This uncertainty leads to an unwillingness to commit resources for fear the activity will be a constant time drain and not provide the anticipated benefit. The change to this thought process begins by drafting a project scope statement so that a team understands there are limits to their focus. I call this written statement ‘the charter’. In IT departments and product development groups, the charter is called a ‘statement of work’. At a high level, the leadership team manages how many of these projects get started and assigns a heavier concentration of resources with a limited time to completion. This is also easily applied to a company using kaizen and can be applied throughout the departments.

“It was great to see people returning to trade shows by attending Label Congress 2021 in Chicago”

After reviewing a company’s list of active or soon-to-be-active projects, I suggest leaders place all projects on hold. I coach executive teams to build a charter of the most critically needed projects immediately and backlog all the rest. The backlog list should be maintained visually and should include active and completed projects as well. If a clear charter cannot be defined, then the projects will die of their weight – perhaps leading to a simplification of the demand. Just listing them can lead to a discussion of the potential impact and degree of difficulty of the projects being proposed. I suggest working on a mixture of easy and difficult problems, but limit the scope of the task for quicker advancement and recognize success. Using these methods, most companies quickly recognize they have too many projects started without crisp definition of focus and completion expectations. I encourage leadership teams to activate no more than three projects for each macro business process, and only activate another when one of the previous projects is completed. No kaizen event or improvement project should begin without a firm charter defining the focus. Companies that understand this process assign resources more definitively. This leads to working on fewer projects, with better-equipped people driving a quicker response time. With this focus, you not only recognize faster completion of projects and great progress to the stated objectives, but also have highly satisfied teams.

Respecting time

Building on a reduced active list, we can now focus our project charters with details that are often overlooked. A charter identifies who will take responsibility for the implementation of the project and is used to set expectations including a start date and expected completion date. It requires planning and thought to avoid a false start and wasting time. A time focus is critical to the success of all continuous improvement initiatives. Sticking to the use of the structural tools being discussed also leads to supporting a philosophy that acknowledges respect for people’s time. Several reports speak to the reasons employees leave companies, and we've also seen reports about companies’ inability to find good people. With our continuous improvement disciplines, we acknowledge that good people are already working in your company. We work to involve these people purposefully and in measured ways to solve both problems of constraint and employee’s involvement. The current employees provide expertise at every level of the organization and engaging them for their knowledge of the process emphasizes their importance. This just does not happen automatically and the charter provides communication for a team to build consensus and rally commitment. It also demonstrates involvement, leading to buy-in, and stimulates conversations around improvement initiatives.

It is exciting to start a chartered improvement project in one area of a company and see how it resonates in other departments. Recently I completed a 5S project in one press work cell. When I returned to the facility the next day, two other cell leaders had already reviewed the charter, developed an action plan, and wanted input on what to focus on so they could improve their cell as well. The goals clearly understood and focused on time, and drove a contagious behavior change. I believe the discipline and focus was something the employees were craving as part of their workday. The common link was a smaller defined project with known success. An outcome was the opportunity to demonstrate respect for the operator's knowledge, time and work.

“Leadership commitment to continuous improvement provides an immediate competitive advantage”

Pushing the concept, executing a project properly requires a leader to gain input from his improvement team, and together they complete the definition of what the future state looks like as a result of the project being implemented. Being visual with these efforts provides communication, expectations and identification of results within the group. Every team performs better with defined expectations. The company leadership, including team leaders, must have enough emotional intelligence to understand that a team member is providing their expertise and extra time solving a problem and this garners respect.

Diving deeper into the details of project management we increase visibility to accomplishment by noting the actions needed, the responsible person, and expected completion timeline. This commitment is captured in the form of a dot matrix or 3W (who, what, when) action plan. In a visual factory, this is usually a dot matrix format about the size of an easel pad. This visual commitment demonstrates to the rest of the team not only a commitment to the action but a commitment from team members to their team. Completing the tasks demonstrates respect for the team’s time. No one wants to miss a commitment date when it means it will hold up progress to other actions.

The ability to demonstrate closed actions in support of a team provides a sense of accomplishment that is also infectious. This is the genesis of positive momentum and drives new conversation and commitment from within. This is how companies drive involvement, creating a positive culture that resonates with their employees. I can promise a significant increase in the number of projects completed without hiring new employees. The talent is within your walls today, and the leadership team focused on a culture of excellence will find a windfall of capability that will drive competitiveness by reducing response time, eliminating quality bottlenecks, resolving the old issue, and elimination of process waste will yield reduced cycle times. Leadership commitment to continuous improvement provides an immediate competitive advantage in an environment that fosters a winning feeling. Your employees go to work knowing they are recognized for their contribution to positive results. Winning in this environment is fun.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.