HP looks ahead to ‘Indigo First’ digital future

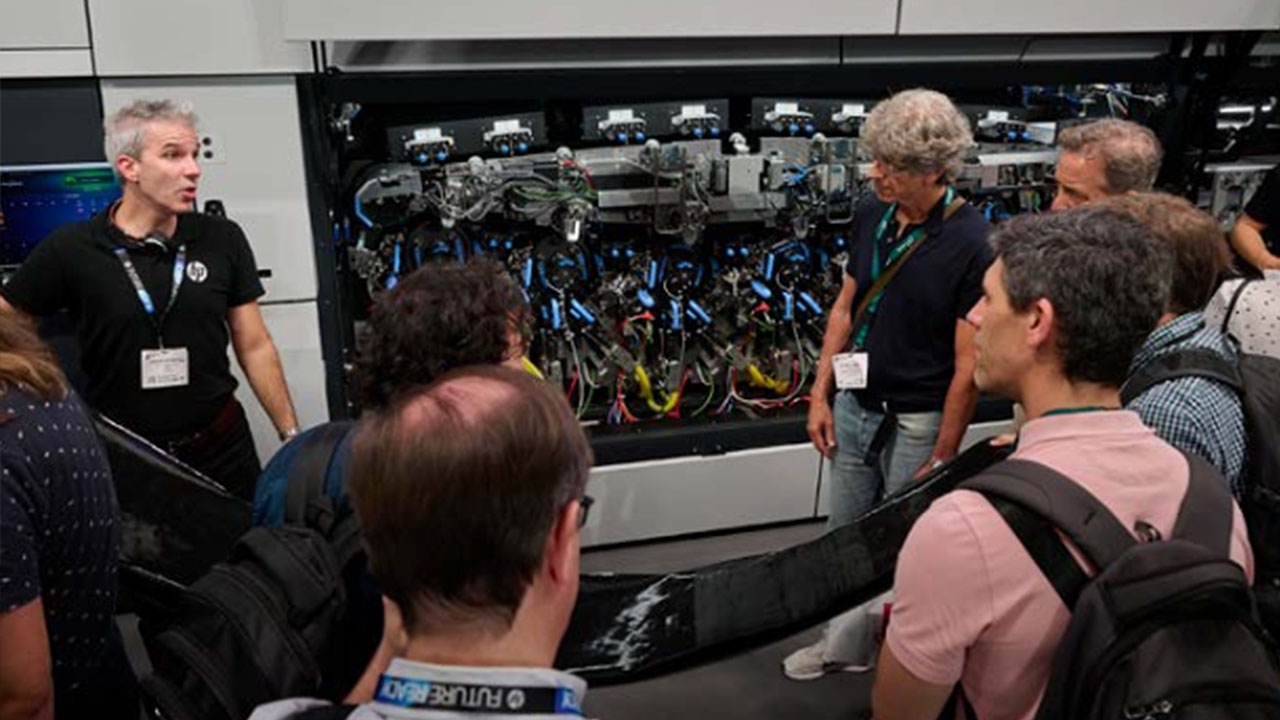

Labelexpo Europe 2023 saw HP Indigo demonstrate a suite of products designed to allow converters to operate inside a fully digital ecosystem. HP’s Haim Levit explains the concept.

HP Indigo at Labelexpo Europe 2023.

Haim Levit, senior vice president and general manager at HP Industrial Print, believes a very successful Labelexpo Europe 2023 represents a watershed moment for the company – the first step towards building a global community with a digital mindset transforming the industry.

‘We have sold 8,000 presses to 5,000 companies across both the commercial and packaging spaces, including 2,000 6K‐series presses. What I’m trying to achieve is to build that into a global HP Indigo community that helps our customers to be part of something much bigger,’ explains Levit.

This is not simply a matter of label and packaging converters buying more digital printing equipment. It’s also about the eco‐system of some 200 OEM partners HP has built up across prepress, coating, finishing and packaging systems, which allow converters to adapt their business to rapidly changing requirements.

Levit says the press technology HP Indigo introduced at Labelexpo Europe 2023 will allow converters to fully operate within a fully digital eco‐system and create new business models that dovetail with emerging trends across the supply chain. ‘Providing proven digital printing for all types of print runs is, in short, our main intent,’ he says.

‘Today’s market trends, reflected in the state of the industry, are characterized in part by converter consolidation alongside consumers and brand owners demanding agility and sustainability. These trends are creating market conditions in which digital delivers tangible benefits to navigate a complex production landscape where converters need to adjust production plans and types of substrates very quickly. This is precisely where the HP Indigo mindset unlocks higher efficiency, and shorter delivery times, resulting in increased productivity and higher ROI.’

Game changer

In this context, Levit describes the HP Indigo V12 as a ‘game changer’.

‘The V12 is a 24/7 printing line that allows label converters to replace more than one flexo press. Indeed, one of our beta testers, Brook & Whittle, says two V12s would replace eight legacy flexo presses. The V12 needs only one operator compared to various specialized manpower required around a flexo press, and we are constantly working with our partners to provide more automation solutions to make the production flow more seamless.’

As an example, Levit points to the launch at Labelexpo Europe 2023 of ABG’s high‐capacity automated unwind and rewind modules for the V12.

With the V12, capable of flexo‐matching speeds up to 120m/min in six colors, finishing can be the bottleneck. But Levit says HP’s partner network is already working to tackle the issue. ‘JetFX is now working with ABG on end‐to‐end automation of the embellishment process.’

Given the high productivity of the V12, will it now replace the HP Indigo 8000? ‘Absolutely not,’ confirms Levit. ‘The HP Indigo 8000 is still in the range as not all label converters will have that volume requirement to feed a V12’. The other major launch at Labelexpo Europe 2023 was the mid‐web HP Indigo 200k press, a successor to the hugely successful HP Indigo 20000 which first allowed converters to digitally print flexible packaging on an industrial scale. Now undergoing final beta testing, the 200k offers a 30 percent speed increase over its predecessor and a claimed 40 percent increase in overall productivity.

‘We are seeing impressive volume growth in flexible packaging, breaking new records every quarter,’ confirms Levit.

A major reason for the success of the 20000 was HP Indigo’s market‐shaping ability to encourage OEM partners to build an entire eco‐system around the press, which was demonstrated at Labelexpo Europe 2023 in the Digital Pouch Factory. The output of the 200k press was sent to a thermal laminator then a pouch‐making machine supplied by Karville, with digital embellishment provided by a JetFX digital print bar mounted on an ABG Digicon line.

The final part of the interlinking print system demonstrated at Labelexpo Europe 2023 was a 6k press shown in the context of a fully integrated and automated web‐to‐print operation. HP’s OEM partners here included the Web2Pack e‐commerce solution for small brands, an ABG Digicon Series 3 finisher with digital embellishment and laser die‐cutting, and the Storefront solution from Infigo.

Beyond the machinery, a central part of HP Indigo’s automation strategy lies in the roll‐out of its new PrintOS Suite, a cloud‐based operating system that integrates software and data tools into print production. This Cloud‐based workflow will enable converters to get more out of their existing presses. HP Indigo PrintOS Suite adds intelligence to machines reaching new quality and production levels. As an example, the latest version of HP’s Spot Master color matching system, launched at Labelexpo 2023, allows color information to be shared by converters with their brand owner customers via a secure Cloud link. This version of Spot Master also allows calibration of HP Indigo presses across multiple sites.

Industry trends

What did Labelexpo Europe 2023 tell HP about wider industry trends?

Says Levit: ‘Over the last five years, we have seen our customers overcome several challenges. From paper mill strikes, destocking, rising costs and inflation, and a host of other obstacles, but the print industry has remained solid throughout. The recent summer period has not only restored the demand levels observed in 2022 but has also unveiled promising indicators of new growth trajectories. Notably, there’s a discernible trend of converter consolidation and destocking, which has primed the industry for a new phase of expansion. Overall, the label industry is experiencing a year‐over‐year growth rate at nine percent.’

Levit reports that one of the encouraging observations people were talking about at the show is the consistency in demand levels and the transformation of the way companies work.

‘Converters want to invest money to upgrade their fleet and be able to convert solutions that enable end‐to‐end automation from order to labels. In fact, automation is indeed one of the key trends for 2023, and its importance is increasing across industry segments. As I have said, for the HP Industrial business, this is a key component of our strategy. We are taking our learnings from advances made in other markets such as commercial and photo and bringing them to the labels industry.’

In conclusion, Levit states that labels and flexible packaging are ‘substantial markets with a significant potential to further lead the analog to digital transformation with more automated process management and greater sustainability. As we look ahead, our customer priorities and requirements will remain central in shaping our ongoing innovation. You can expect new products with LEPx technology, workflow automation, and sustainability at the core. We are excited for the future and looking forward to leading the next chapter of label and flexible packaging production.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.