Durable labeling for electric vehicles

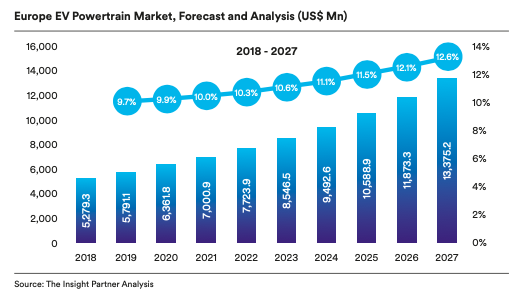

Electromobility is gaining momentum. There are already over 10 million fully

or partially electric cars on the roads worldwide. Significant growth is forecast for the coming years. With the expansion of range, economy and charging infrastructure, acceptance and demand for e-vehicles continue to rise. Studies estimate that they will account for up to 20 percent of passenger car sales from 2030. The future belongs to e-mobility.

To support this electronic future – which makes an important contribution to reducing C02 emissions – 3M has developed reliable marking systems for electromobility.

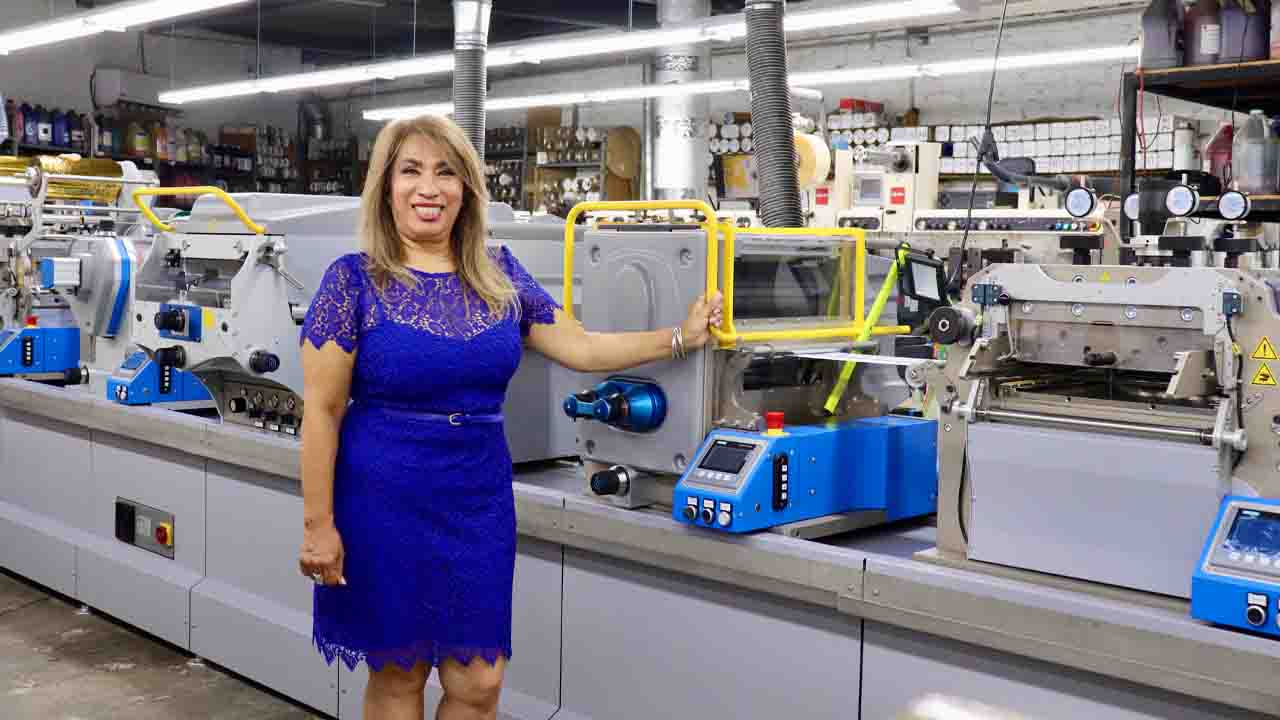

The company has been supplying the automotive industry for more than 100 years, gaining vast experience in solving even the trickiest of marking problems. Its in-house laboratories are equipped to the latest standards to perform and document internationally recognized test procedures.

Reliable adhesion and good legibility

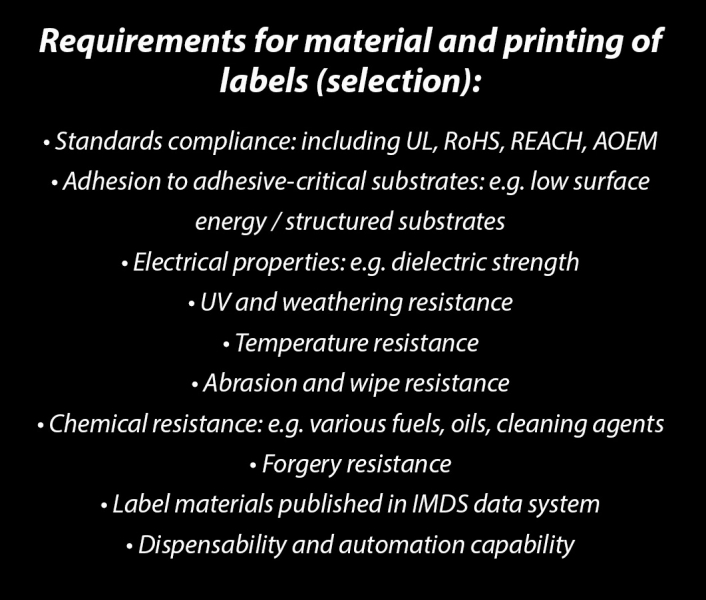

The top priority for technical markings is reliable adhesion and good legibility over the entire service life of a vehicle. To ensure this, the marking system must perfectly match the requirements of its installation location.

The film, adhesive and printing of a 3M label are tailored to the respective requirements, allowing it to reliably withstand extreme stresses over the long term – such as UV radiation, extreme heat and cold, mechanical forces, and contact with moisture or chemicals.

Electromobile transition is also a dynamic field of development for marking. The innovative designs of electric and partially electric vehicles bring with them individual challenges: new components and installation locations, new materials and processes, new expectations and standards.

The top priority for technical markings is reliable adhesion and good legibility over the entire service life of a vehicle

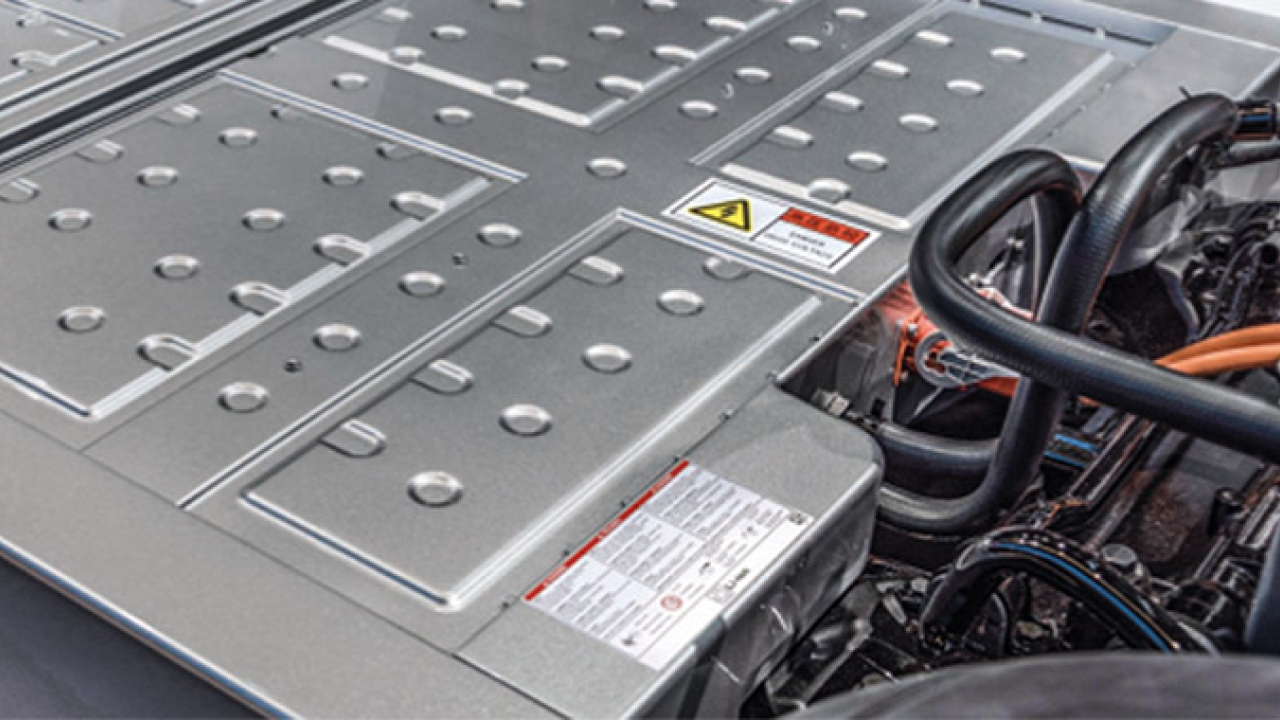

Each new component has its own applications with specific requirements, whether on the battery, electric motor, power electronics, charging connection or cable.

Key trends in labeling for electronic vehicles include lightweight materials, safety, and multiple markings.

Because of their low weight, components made of plastics such as PE or PP are often used by manufacturers. This necessitates films which can successfully mark low-energy surfaces. Protection against tampering, theft and transfer is provided by security markings as well as laser-markable label films.

Because of their low weight, components made of plastics such as PE or PP are often used by manufacturers. This necessitates films which can successfully mark low-energy surfaces. Protection against tampering, theft and transfer is provided by security markings as well as laser-markable label films.

And there is a trend towards more labels per component. Multiple labels are common to be able to flexibly install the same components in different vehicle types. Additionally, more labels are prescribed for specific topics such as recycling.

Applications

Batteries are at the heart of the electric car. Lithium-ion batteries are used in most vehicles. Complex requirements are placed on their labeling, and these can vary depending on the manufacturer, legal regulations or application.

When labeling cables, labels over small radii, curves, corners or edges need to be very flexible so they do not develop restoring forces. 3M films for cable marking enable optimum anchoring and durability thanks to their combination of conformability and strong adhesive strength. Applied professionally – as a cable flag or wrap-around label – they guarantee long-term reliable marking.

The cable flag encloses the cable in full contact with the substrate. Chemicals, liquids and dirt cannot penetrate. The two ends are glued together to form a protruding flag as an information carrier. Wrap-around labels, meanwhile, are printable labels and transparent protective films in one. Wrapped twice around the cable, the transparent protective film covers the printed part like a laminate. Thus, all information is protected from environmental influences.

The cable flag encloses the cable in full contact with the substrate. Chemicals, liquids and dirt cannot penetrate. The two ends are glued together to form a protruding flag as an information carrier. Wrap-around labels, meanwhile, are printable labels and transparent protective films in one. Wrapped twice around the cable, the transparent protective film covers the printed part like a laminate. Thus, all information is protected from environmental influences.

3M security labels transport information and protect against manipulation, replacement and theft, since they self-destruct when detached. They are additionally a reliable guarantee for the brand authenticity of components.

Type plates made of 3M laser-markable foil are forgery-proof and extremely durable. The foil consists of two differently colored layers.

Testing

Standardized testing and documentation of all relevant properties of a marking system are prerequisites for its industrial use. For decades, 3M has supported suppliers and automotive manufacturers in specification processes and individual material testing. 3M laboratories are equipped to ensure that tests can be implemented according to the latest standards. All 3M product recommendations are based on valid laboratory tests and practical experience. It all depends on what the application requires.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.