Embellishments shine at Wright Global Graphics

The North Carolina-based label converter produces some labels that you have to turn over to see, while others are destined to jump from the shelves. In both instances, value added effects such as foils, embossing, debossing and tactile effects play a role in portraying a product as premium.

‘We’re always trying to figure out a new way to embellish a product,’ Wright says.

Wright Global Graphics produces woven labels for the mattress and upholstery industries, as well as heat seal labels for floor covering. Additionally, the company creates pressure-sensitive prime labels for the food, wine, craft beverage and candle markets.

The second-generation print shop was started in 1961 in Thomasville, North Carolina, where today Wright Global Graphics operates three plants as well as a facility in Dalton, Georgia, close to many of the country’s carpet mills. The company, run by brothers Don, Ron and Greg Wright, is celebrated as a small-town employer, as evidenced by a recent local TV news report that described the manufacturer as ‘a staple of the downtown.’

Wright Global Graphics also has a facility in Hong Kong, though the company remains passionate about American manufacturing.

Don Wright says: ‘I truly believe our country was founded on manufacturing. As Americans, we love making products. That is what helped our country grow to prominence. And it’s what makes our country great.’

‘Sparkly stuff’

Embellishment is a large part of the value Wright offers to its label customers. The way Don Wright sees it, if the company’s customers put the time, energy and money into making their products, that mentality should extend to the packaging.

‘To cut yourself short at the point of contact with the customer is insanity to me,’ he says. ‘It makes absolutely no sense to drop the ball on packaging. The label should represent what’s inside the bottle. It’s a critical point of contact with the consumer, and it’s the last place you should cut a corner.

‘At the end of the day, the sparkly stuff is what you want. If it’s sparkly on a store shelf, I’m going to gravitate toward it. It attracts attention, and if the product is in an environment where it needs to stand out, foil is a really great way to do that.’

The paradoxes that exist at Wright Global Graphics are best demonstrated by its machinery. On the shop floor sits some of the oldest invented technology, alongside to the latest state-of-the-art equipment.

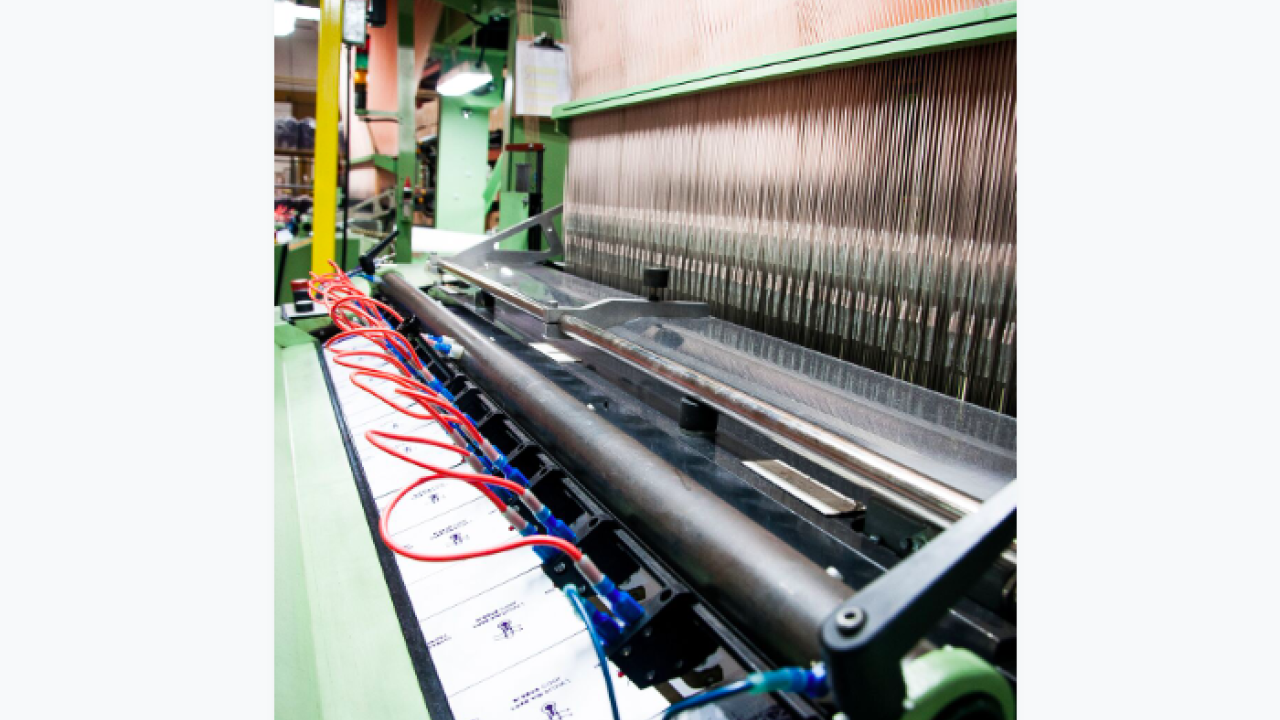

A powered fabric loom is used for the woven labels for floor covering, upholstery and mattress labels produced at Wright Global Graphics. The company also has a range of sheet-fed offset, flexo and digital technology for its labels.

A Mark Andy Performance Series P5 is the workhorse of Wright’s flexo operations, alongside an HP Indigo 6800 with off-line AB Graphic Series 3 digital finishing unit. Wright uses Kluge foil stamp and embossing machines for fabric, paper and film substrates, and is a loyal customer of Kurz for foils.

Despite woven labels often not facing the customer, Don Wright says, they are anything but generic. In fact, the floor covering, upholstery and mattress labels are treated much like the prime labels produced at the company.

He explains: ‘Customers purchasing rugs or mattresses still want to feel that their products are premium. It’s an information label but it’s the only other branding you have.’

‘With any decorative rug, consumers are basically buying pattern, color and texture. Floor covering brands use the label on the back to communicate SKU, barcode, size etc. But it’s also the only opportunity the manufacturer has to say “this is who we are”. The rug doesn’t have their logo on it. The label is the place for them to say “this is high end”.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.