GOpak launches digital flexible packaging start-up

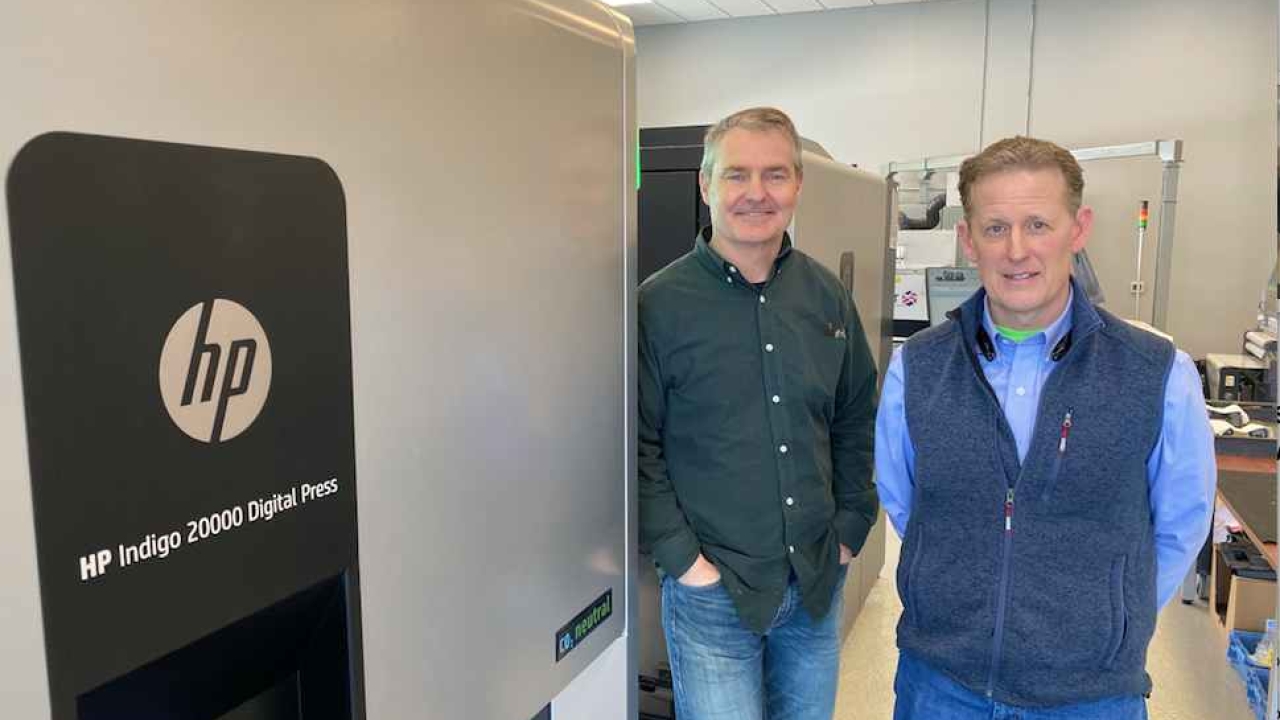

Buran spent 25 years with WS Packaging. Eying the disruption and growth in the flexible packaging production, he saw a growing demand for small and medium run flexible packaging jobs. Buran teamed up with Hotchkiss, a 27-year veteran of the plastics machinery business, and together the duo created GOpak, which opened in a 10,000 square foot space in May 2019.

A 30-inch wide HP Indigo 20000 digital press is the backbone of the operation, supported by cutting-edge eBeam technology and a Karlville slitter

‘Many container packaging segments are moving to flexible packaging, including food and beverage, health and beauty, and other consumer products,’ Buran says, ‘However, smaller brands are not able to get high-quality printed pouches due to large minimums and plate costs. Smaller brands are typically forced to buy blank pouches and label them, and now with the HP Indigo 20000 the emerging brands can eliminate the label and compete with the bigger brands and gain shelf appeal.’

In addition to meeting demand for small and medium packaging volumes, GOpak was established on a philosophy of speedto-market and improved sustainability, or ‘fast and clean,’ as Buran says.

‘Our technology promotes what our business is all about: fast and clean,’ he says. ‘And by that I mean offering a faster time to market and being more sustainable. We want to be the printer of choice for our ability to supply high SKU, low volume, fast turnaround, high quality, sustainable packaging.’

GOpak’s business model is attractive to many small and medium brands, Buran says, because they take less risk by ordering smaller quantities and increasing their cash flow. Brands are also attracted to the benefits of personalized or versioned packaging.

‘I saw what was happening with large companies as brands need to refresh their packaging often,’ he says. ‘That trend is continuing and will only grow as more and more companies realize the benefits.’

The company has already noticed the demand in the 10 months since opening. ‘Opportunities are out there,’ says Buran.

Production

GOpak provides stand-up pouches and roll stock packaging to printing and packaging companies and CPGs. Many of its orders are from trade printers and food and cannabis companies.

GOpak surface prints on pre-laminated structures and follows that with eBeam curing, allowing the company to ship printed rolls in a few days. Pouch production is completed with off-site partners pending the style needed.

The 30-inch wide eBeam system allows GOpak to create gloss, matte, and soft touch finishes. The ‘liquid lamination’ curing technology uses a thin layer of coating to cover and protect graphics and prepare the material for converting. And the durability of eBeam curing, which cross-links the varnish, inks and material as one, can eliminate a lamination layer, providing sustainability advantages that are important to its business model, Buran says. eBeam technology cures instantly and uses no photo-initiators, making the process safe for food applications.

GOpak installed S-OneLP’s first CatPak system. The system combines an eBeam curing system for packaging film, a corona treater and 30in web unwind and rewind modules, integrated into the eBeam curing system base frame. The system takes up less than 300sq ft.

‘The CatPak, with its eBeam curing technology, is superior to traditional methods of finishing, eliminating the lamination and set aside time,’ says Buran. ‘This allows us to slit and convert immediately, enhancing our speed to market. With no lamination needed, it opens opportunities for recyclable and compostable pouches and films.’

The development of the CatPak system was a partnership between S-OneLP, Tim Burke at Custom Design Applications and PCT eBeam and Integration.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.