Gurong Printing embraces digital

Explains Gurong’s founder and director Lawrence Zhang, ‘Gurong Printing was set up less than four years ago, but our participation in adhesive label printing can be traced back to 1998. Previously, our company was located in Jiading District, Shanghai, as a subordinate branch of the Shanghai Zhanwang Computer Advertising Printing company. As business increased and we met more demands to transform to more sustainable practices and introduce digital printing technology, we registered Gurong Printing in 2015.’

New machinery

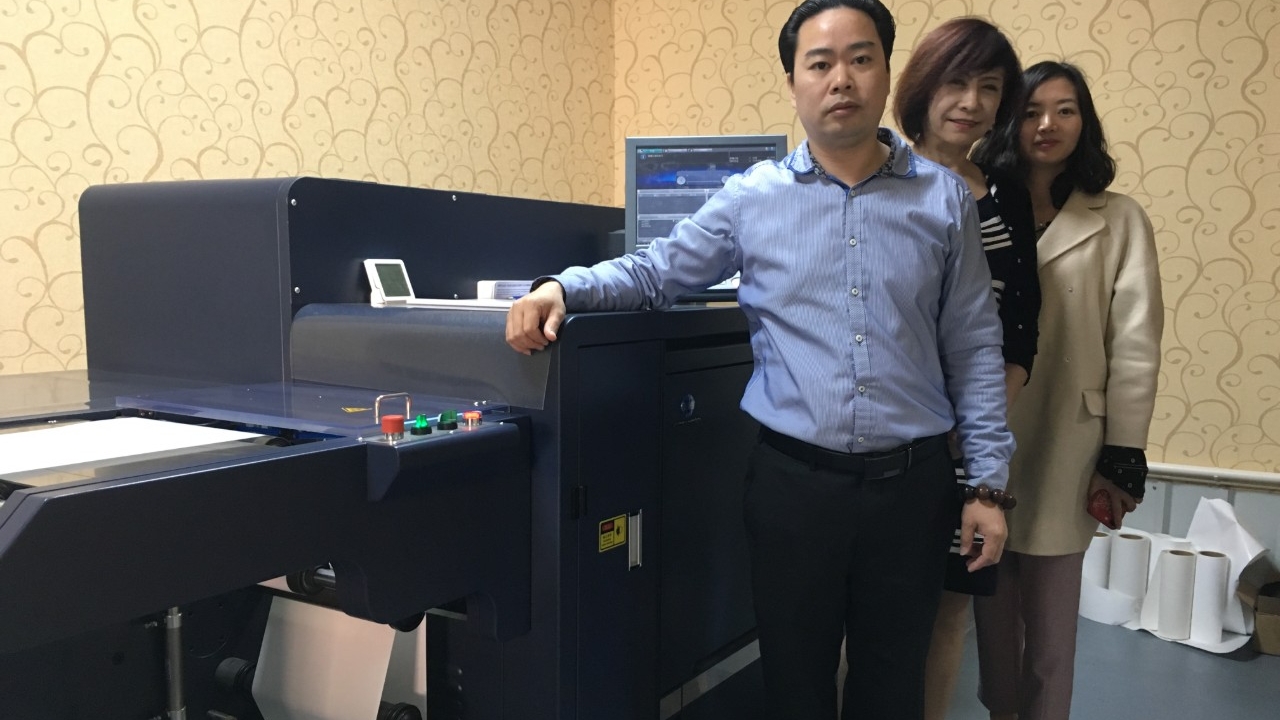

In 2018, Gurong Printing installed the first Konica Minolta AccurioLabel 190 digital label press in eastern China, and in April purchased its second digital press – the latest KM AccurioLabel 230.

‘As with our original intention to establish Gurong Printing, we are aiming to follow the latest trends in the adhesive label printing market and retain the capability to keep innovating and transforming the business,’ explains Lawrence Zhang.

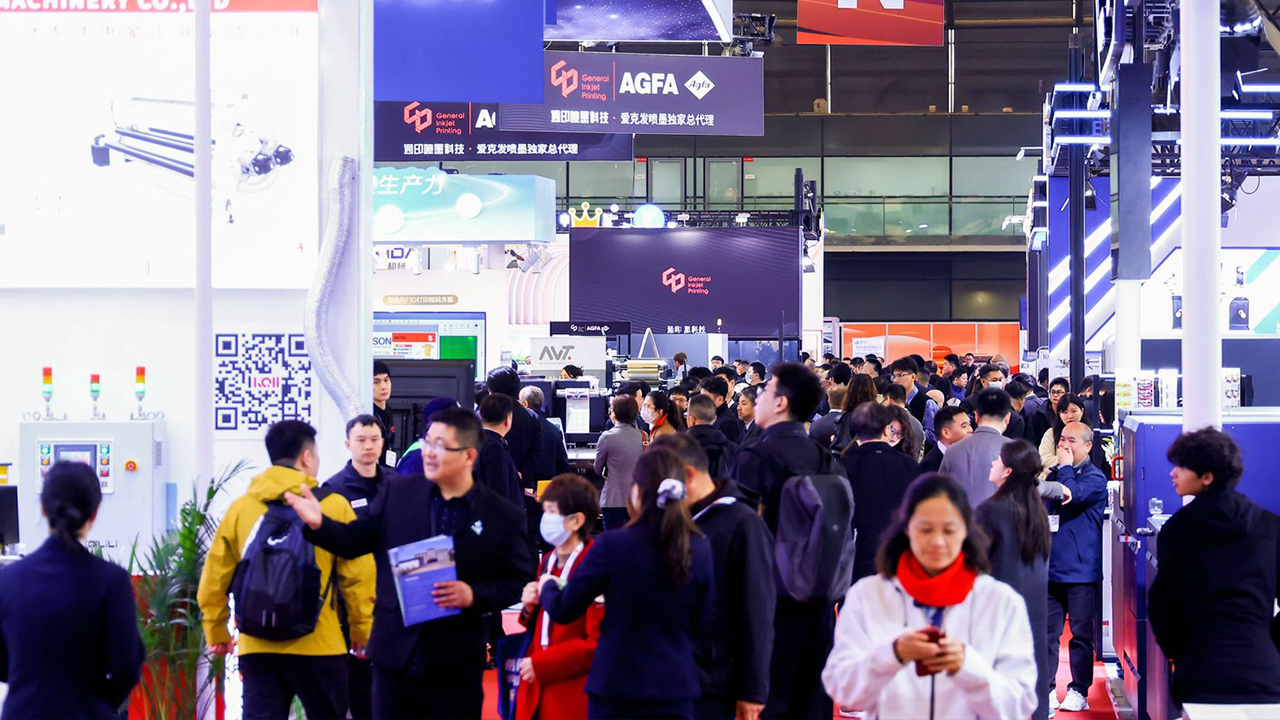

Recent years have seen increasing requirements from end users for short-run orders and personalized products, which has put pressure on label producers regarding production speed, lead time and cost control. And with the improvement of digital printing technology, more and more Chinese label converters are adjusting and moving into digital production.

‘Actually, we first tried digital printing five years ago,’ says Lawrence Zhang. He selected a second-hand digital press and went to Beijing personally to see it in action. However, once installed, the press malfunctioned frequently and was not suitable for full scale production. It now lies unused in the warehouse.

Looking back, Lawrence explains there were not many brands of digital label equipment in the Chinese market at that time, and technical support was not as developed as it is now. What’s more, he did not know much about the technology and the company had not prepared for it. So the failure was understandable.

That experience made him more cautious when he later selected a new digital press. ‘The production mode of a digital press is completely different to a traditional printing press. We don’t have practical experience using digital equipment and we have not been able to try for all the different kinds of label with a digital press. In this regard, we are more concerned about the brand reliability of the press rather than the machine itself,’ said Zhang. ‘The performance and reputation of Konica Minolta across a wide range of digital press applications eliminated our anxiety to a large extent. We trust this brand, and we believed they could handle any problems which we may meet when using the press.’

Zhang says that the electrophotographic toner print technology of the AccurioLabel 190 provides more stable and brighter colors, ‘and the color gradient effect is splendid. In particular, the digital press completely eliminates problems of missing dots in the highlight area you find during conventional printing.’

Describing the ‘click payment’ business model, Zhang says: ‘It is cost-effective because we only pay according to printed meters, and Konica Minolta provides all the maintenance and free replacement of spare parts. So it fits perfectly for a small company like us which adopts digital printing for the first time.’

All these factors facilitated investment in a second digital press at Gurong Printing – the Konica Minolta AccurioLabel 230.

Digital transformation

Despite the AccurioLabel 190 digital press only being installed at Gurong Printing in July 2018, today digital accounts for 70 percent of the company’s gross value, with 85 percent of smaller orders printed on this machine. The press has printed over 100,000 running meters a month at peak demand.

Almost 90 percent of labels produced on this press are exported, which requires higher printing quality and shorter lead times.

Gurong Printing is now focusing its abundant technical know-how and professional experience accumulated during years of traditional label production into the digital operation. ‘We will gradually make our traditional equipment obsolete,’ said Zhang. ‘Using one digital press substitutes for three traditional presses, and we are planning on achieving a comprehensive digital-only production capacity.’

Digital transformation is only one step in the company’s brand development. ‘We have. been carrying out our “Gurong Brand” strategy for a long time, looking to win business by quality, sincerity and good service rather than the vicious competition with low price and low quality. We will consistently promote the quality management concept and quality system and standards to the end,’ says Zhang.

He appreciates that this branding strategy requires not only high quality labels but also innovative solutions for customers. ‘This is why we purchased our second digital label digital press. We hope to cooperate with the famous international brand Konica Minolta in unlocking more and the newest applications of digital printing. We will try to become a model enterprise for technical transformation.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.