Haney Packaging looks to accelerate change

In 2017, after being renamed Haney Graphics in 1997 and Haney Packaging Resource Center in 2004, the company was rebranded as Haney Packaging, The Packaging Microfactory.

‘Historically, Haney was always innovation for others,’ says Dan Haney, co-founder and president of Haney Packaging. ‘We would innovate, figure out the issues, prototype the product, put it through testing, vet it, and hand off what we call the recipe card. That was it. But all that changed about four years ago.’

The company has now been re-purposed to assist and guide its customers – typically small-batch, consumer packaged goods companies (CPGs) – in developing labels and packaging that not only stand out in a congested market but also utilize technology that is innovative and sustainable.

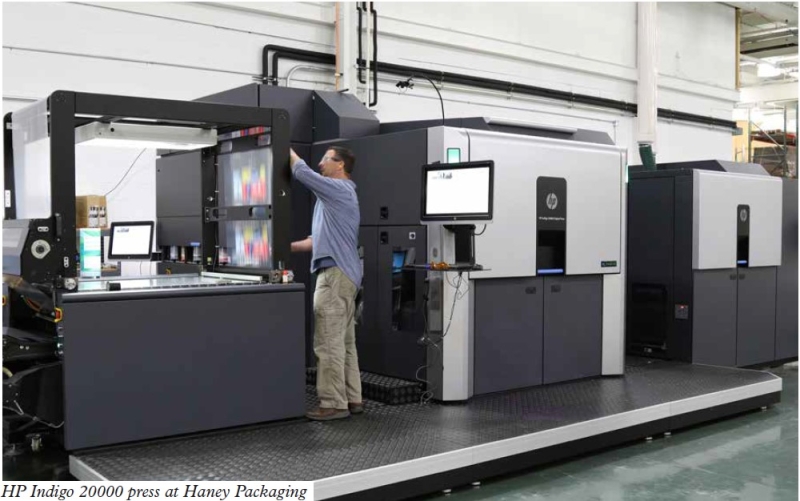

The company’s 105,000 sq ft facility contains a large fleet of equipment, including a 12in HP Indigo WS4500 press and 30in HP Indigo 20000 press, multiple Roland large format digital presses, a 43in Nordmeccanica Super Simplex SL1100 solventless adhesive laminator, a 16in Comco multi-substrate ProGlide 8-color flexo press, and more pre-press and post-press capabilities. The equipment is used to create what Haney calls a ‘mini supply chain,’ where it quickly turns around prototypes and designs to show its customers what’s possible.

‘In the simplest terms, if I had one word for it, it would be an incubator,’ explains Haney. ‘Haney Packaging is focused on connecting early innovation to activation. We do that through a suite of what we like to call a microfactory, a mini supply chain all under one roof. Enabling us to really show and help our customers understand what’s possible.’

From innovation to activation

‘It starts with someone else’s idea, right?’ says Haney. ‘A brand owner has a new product or a variation of an existing product of some sort and, for example, they’re looking for something that’s in plastic they don’t want to be in plastic. And to that extent, we can help influence and shape the overall consumer experience around the packaging itself.’

At Haney Packaging, the process always starts with the design and technical criteria of the packaging. As a graduate of graphic design, Haney believes that the performance and look of the packaging go hand-in-hand.

‘As a designer, I’m very empathetic to the consumer experience,’ says Haney. ‘If the package isn’t beautiful, if it doesn’t evoke something and tug on the heartstrings of the consumer while also meeting those performance criteria laid out, then it’s just going to fail before it even goes to market.’

To understand what the final customer is looking for, Haney goes through what it calls a ‘vision session.’

During the session, which can last anywhere from half a day to two days, the company puts its customers through an immersive experience where both companies discuss the ‘three legs that hold up the stool called innovation at the brand level: design, consumer insight, and technical packaging,’ says Haney.

Haney then figures out which materials can be used not only to make the labels and packaging look nice but be scalable and cost effective for its customer.

Prototyping phase

Next comes the prototyping phase. Here, Haney Packaging utilizes its equipment fleet and full pre-press capabilities to showcase the design concepts developed during the vision session, a process Haney calls ‘informed prototyping’.

‘For us, informed prototyping is a term we use to mean a prototype that understands manufacturing feasibility and what we can and can’t do at a full manufacturing scale. It’s important to note that, when we talk about Haney being a microfactory, it’s across all formats,’ says Dan Muenzer, director of marketing and business development at Haney Packaging. ‘Labels is obviously something that we do, but we also engage with flexible packaging, folding carton, corrugated, tubes, clamshell, almost anything you can think of.’

At the end of the process, Haney Packaging assists its customer with a ‘path to commercialization’.

‘All while we’re converting and prototyping, the customer is taking notes, asking questions and we’re figuring out what worked and what didn’t, developing a path to commercialization or what we call the recipe card,’ says Haney. ‘The recipe card then enables our customers to scale up more accurately.’

For some customers, however, the work doesn’t end here. Haney Packaging also houses a 55,000 sq ft co-packing facility with everything from horizontal and vertical filling machines to steam tunnels to crimpers and sealers. The company mostly focuses on primary and secondary food packaging but is also FDA-certified for level one and two over-the-counter drugs. The co-packing operations are typically focused on test markets, sampling programs, or limited-time promotional packaging.

The range of offerings and capabilities is part of what makes Haney Packaging unique. Haney doesn’t consider the company a converter, but they do some converting. They don’t consider themselves co-packers, but they do some co-packing.

‘If you’re able to look down at our building, we have design capabilities attached to a world-class materials science library, printing and converting capabilities, and co-packing and filling operations right behind us,’ says Haney. ‘At the end of the day, what we’re able to deliver to brands is a total package. From mind to market.’

Invitation VIA Haney

Haney Packaging’s Validation in Action (VIA) program is an invitation-only, open innovation program with partners across the supply chain, with the aim of building a vast library of cutting-edge materials and products that can be used to demonstrate to brand owners just what’s possible when developing new packaging concepts – and also to have an easier way to bring this innovation into its facility.

‘We have a market team that spends a lot of time doing research, but I think the secret sauce is our VIA program,’ says Muenzer. ‘We literally have 33 materials partners who are on the bleeding edge, cutting edge, of packaging development.’

Muenzer believes this has been possible because Haney Packaging does not compete with any of the program partners.

‘Here at Haney, we’re not really a threat to anybody,’ says Muenzer. ‘We have our own lane and because of that, we have created an environment where the entire supply chain feels comfortable coming here, collaborating, and developing together.’

The current partners on the program include a wide array of material and raw material suppliers, including resin manufacturers, film extruders, paper manufacturers, coating manufacturers, adhesive manufacturers, ink manufacturers, and more.

Although offering a vast array of possible technology solutions, the program has recently been dedicated to sustainability. This means helping not only the large CPGs reach the fast-approaching sustainability goals, but also the small and mid-size companies that don’t have access to the R&D capabilities of the multinational corporations. That, according to Haney, is where the change starts.

‘If you really want to affect changes in the industry, you have to go to the small-to-mid tier players,’ says Haney. ‘If you give them all the same tools the larger companies already have access to, the whole process is accelerated.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.