IL&P finds success in wide format

Converters expanding into new printing formats is not unknown, but there is always a risk as a successful expansion is never guaranteed.

In 2016, US converter International Label & Printing Company (IL&P) expanded into wide-format printing, mainly outputting point-of-purchase graphics and signage for retail clients. However, due to an increasing workload and demand for quicker turnaround, the company had some issues keeping up with what customers needed.

‘The machines we had could make anywhere between eight to ten sheets per hour and we had about two or three days to produce these products,’ says Mark Turk, president and CEO. ‘Based on those figures, it made it tough to meet deadlines, so we ended up subcontracting a lot to people who had faster machines.’

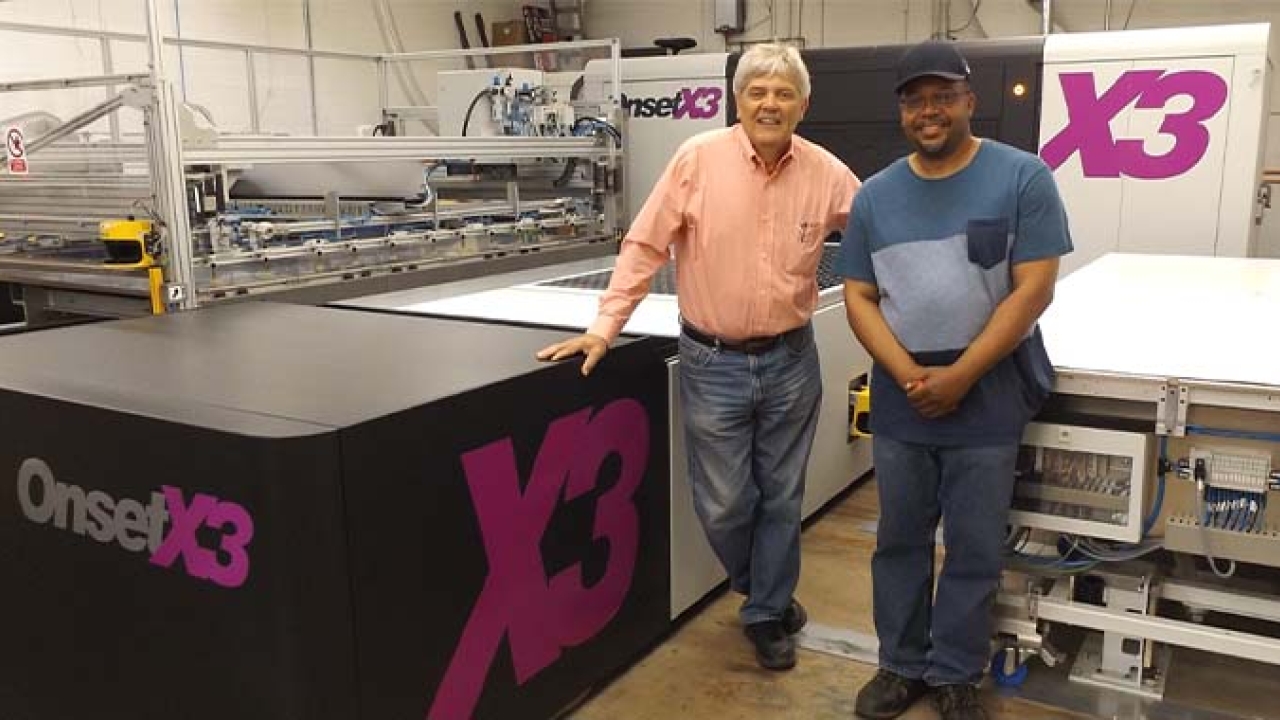

Though the subcontractors were putting out quality products, this deal led to a loss of revenue and profit, so IL&P wanted to bring control and accountability back in-house. In 2019, it purchased an Inca OnsetX3 UV inkjet flatbed press with three-quarter automation.

Located in a 5,000 sq ft facility across the street from the company’s main 15,000 sq ft plant in Elk Grove Village, Illinois, the Inca OnsetX3 is capable of printing upwards of 9,600 sq ft per hour and features three CMYK ink channels plus white or orange. The speed of the press was, according to Turk, the driving force behind the investment, as it can print virtually ten times faster than IL&P’s original wide-format presses.

Capable of printing on a variety of substrates including corrugated, PVC and polystyrene boards, the press has allowed the company to expand into new verticals, opening business opportunities within and outside of its established customer base. It also helped IL&P win awards, including three Best of Category prizes at the Great Lakes Graphics Association in 2020.

According to Turk, the purchase of the OnsetX3 is in line with IL&P’s typical method of investment. ‘It’s typically been that a customer asks us if we can do something either faster or on a different material, for example, and we try to do it with what we have but we figure that sooner or later we will have to invest in equipment to keep up,’ says Turk. ‘Whatever residuals come with it are of course great, but it’s always easier to make the decision on an existing customer’s needs rather than buying something and hoping it helps generate revenue.’

Turk says that this business model has been successful for IL&P. For example, after working with a barbecue sauce producer, IL&P was approached by a handful of other barbecue companies to produce its labeling, leading the company to be known as the ‘barbecue sauce people’ for a while.

Over the years, this has happened a handful of times: new customers coming to IL&P because of work done for an existing customer.

It’s easier to make the decision on an existing customer’s needs rather than buying something and hoping it helps generate revenue

From working with a local craft brewery to help design its bar to using digital presses to print hand sanitizer labels, the company tends to take business as it comes. It figures out how to solve a problem for its customers, while reaping any residual benefits later.

Supply and demand

IL&P is what is typically referred to as ‘generalist’: a converter which serves three or more end user sectors.

Outside of wide-format printing, IL&P works with several companies within markets such as food and beverage, consumer goods and industrial labeling, utilizing seven presses – ranging from digital to flexo to hybrid – and printing a wide variety of labels.

According to Turk, the company can print anything that comes in a roll, always looking to accommodate any customer that comes its way. ‘You’re never really sure about any market. You think something is going to last for a while then suddenly it gets wiped out. Everything can change from one morning to the next,’ says Turk, who worked at the Chicago Sun-Times, a daily newspaper in Chicago for 11 years.

Though Covid-19 has seemed to slip into the background – and the label industry has not seen significant dips in many markets during the pandemic – the virus’ knock-on effects are still emerging. Take, for example, the supply chain.

For suppliers, supply chain disruption has led to longer shipping times, causing shortages and a higher price point on some of the materials used by converters.

In order to get ahead of the lengthy lead times, IL&P is ordering larger amounts of supplies to ensure it has the right products to keep up with customer demand, and storing them wherever they can fit.

'You can’t afford to not have the supplies. If the customer really needs this product, they’ll just go out and find somebody who can give them what they want,’ says Turk.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.