Andy Thomas-Emans: Lights out?

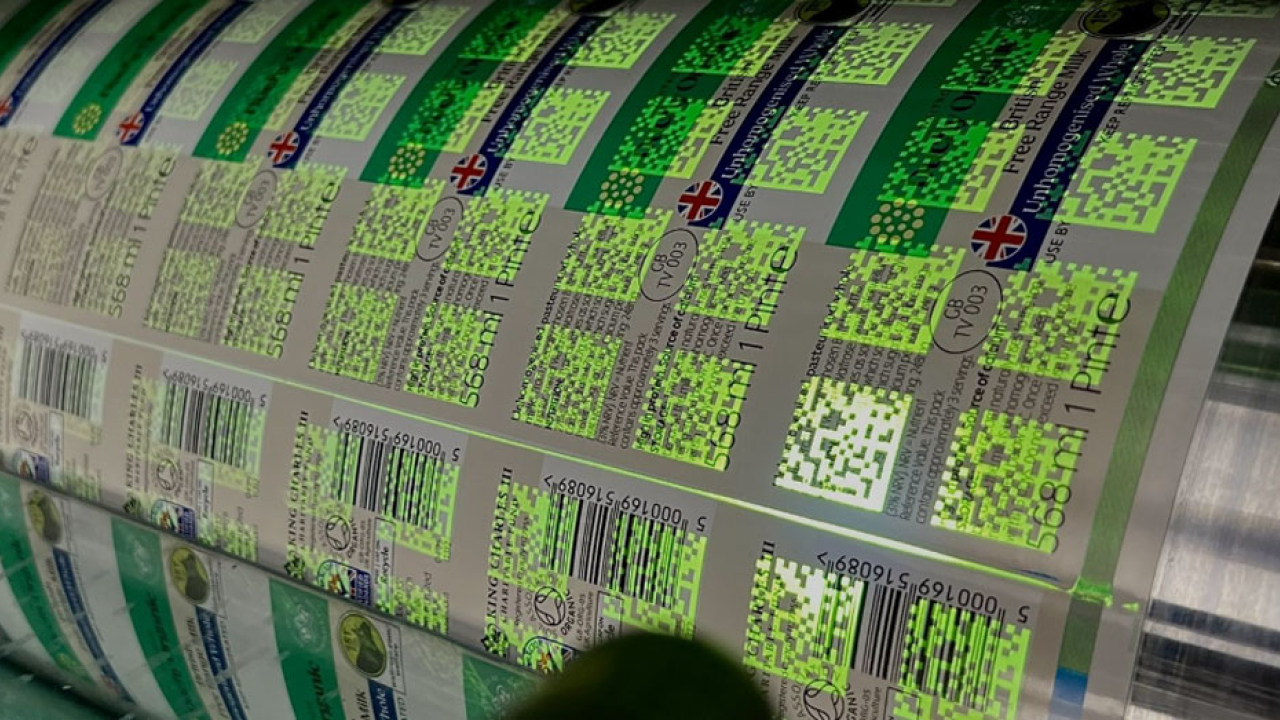

Labelexpo Europe 2025 saw suppliers talking about the future of ‘lights-out’ manufacturing, and not only in digital, but also in flexo production.

Labelexpo Europe 2025 was an exciting show for those with a keen interest in smart automation.

We have reached a point where flexo technology has reached something of a plateau in terms of speed and basic automation.

We have seen full integration of servo motors into flexo presses, even in ‘entry level’ machines, allowing automation of key press parameters like tension control, registration and print pressure, along with the ability to store and recall these parameters.

Automated sensing and closed-loop pressure adjustment is also being applied to die-cutting. Narrow and mid-web press speeds are unlikely to increase significantly due to the need to run multiple processes and properly cure/dry the running web.

The next major leap forward is integrating these technologies into smart automation networks, driven by machine learning and sector-specific AI datasets.

Nilpeter is now talking openly about its ‘Darkroom’ project for flexography, and during a recent fascinating day spent at the company’s demo center, we discussed how that might develop.

Nilpeter already has its ‘Digital Shadow’, a virtual, real-time representation of the press, which means the press can be remotely monitored and even stopped and started remotely. Add to that the ability to carry out a completely automated job change while the press is running, with zero operator intervention, and we can see that, although it is the same FA-17, its smart automation capabilities have advanced dramatically.

When we look back at Labelexpo Europe 2025, I believe we will see it as a pivotal event

Where might robotics come into the equation? LemuGroup, also nominated for an Innovation Award in the first L&L Label Awards, has already demonstrated automated end-of-line automation, taking inspected rolls from turret rewinds, packing, stacking and labeling transit boxes.

But what about the press itself? Could a robot remove a complete flexo printing or converting group and replace it with a pre-loaded group while the press is running?

Meanwhile, smart, AI-driven inspection technology is driving forward, as we will see at Labelexpo, with the ability to predict issues in print and converting and suggest troubleshooting steps.

But as discussed with Nilpeter CTO Carsten Clemensen, the next stage is for the cameras to directly and autonomously control press settings in real time. These cameras would need to be compact and cheap enough to fi t into every print and converting unit of the press and converting line with sufficient resolution and networkable, adaptable intelligence.

Interestingly, Clemensen’s last job before joining Nilpeter was MD at B&R, a division of industrial automation specialist ABB, which already develops AI-driven camera systems for other industrial segments. So, he speaks with some authority here.

Not so sci-fi

The idea of a ‘lights-out’ flexo operation would have sounded like science fiction just a few years ago, but all the technology elements are in place in different parts of the high-tech industrial landscape.

These same advances will also apply to converting machines. We have already seen how ABG, Cerm and Screen came together at Mercian Labels in the UK to automate a fully servo-driven ABG Digicon with all programming carried out remotely via JDF/JMF. This meant the only operator intervention was loading the flexible die. And at the last Labelexpo Europe Automation Arena, Grafotronic demonstrated how camera systems can monitor die-cutting and slitting quality. When linked to print inspection, this allows fully checked rolls to be packed for a customer or put into stock without the need for an extra step of moving to an inspection-rewinder.

The final link in the chain is integration of the press or converting line into wider factory networks, working closely with pre-press and MIS specialists to allow the press to seamlessly deliver real-time production, quality assurance and machine monitoring data to a network and to be able to download new jobs directly from the MIS.

This latter stage is important to prevent the need for an operator double-keying jobs at press side, which is currently the way flexo presses are set up.

In the future, label converters will not only be concerned with gathering real-time production data, but also the energy consumption and carbon footprint for every job that runs through the press, including measurements for substrates, inks and coatings. Labelexpo Europe visitors can see how this works in practice at the Label Trail feature, where CarbonQuota is working with partners Xeikon, Esko, Cerm, GM and Kurz to demonstrate the collection and reporting process for carbon emissions.

When we look back at Labelexpo Europe 2025, I believe we will see it as a pivotal event. Not only because of the move to Barcelona, and not only because the show stretches out in a natural evolution toward short-run flexible packaging and folding cartons, but because it addresses absolutely key issues for the long-term sustainability of the converting industry.

How can we function without a regular supply of skilled machine operators coming into the industry? How can we leverage AI and automation to reduce waste, increase efficiency, increase machine uptime and satisfy the demands of end users for real-time information on sustainability metrics?

I look forward to seeing you in Barcelona!

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.