Novicod revolutionizes interactive packaging and labels

In an industry racing to adopt smart packaging technologies, Novicod is working on embedding connectivity directly into the printing process.

At the core of Novicod’s offering are patented technology units that embed interactive features directly onto the label

The packaging industry is at a technological crossroad. While RFID and NFC technologies have long promised to revolutionize supply chains and consumer engagement, their integration has often meant adding separate ‘smart’ labels to packaging, an inefficient approach that limits scalability. Raviv Banaim, CEO of Novicod, believes there’s a better way.

Implementing RF technology as an add-on process has created significant barriers to widespread adoption, Banaim says, adding that the additional production steps, increased costs and logistical complications have prevented smart packaging from reaching its full potential. Banaim became aware of these challenges through his extensive product development and manufacturing optimization work.

‘Adding RF smart label stickers to every product was not a realistic or scalable solution: not for brands, manufacturers or the supply chain as a whole,’ explains Banaim, whose background in machine and electrical engineering has centered around end-to-end product development and optimizing new technologies for manufacturing processes.

This realization came during his work on a consulting project that explores integrating RFID tag components, conductive paste and microchips within print applications.

Embedding intelligence at the press

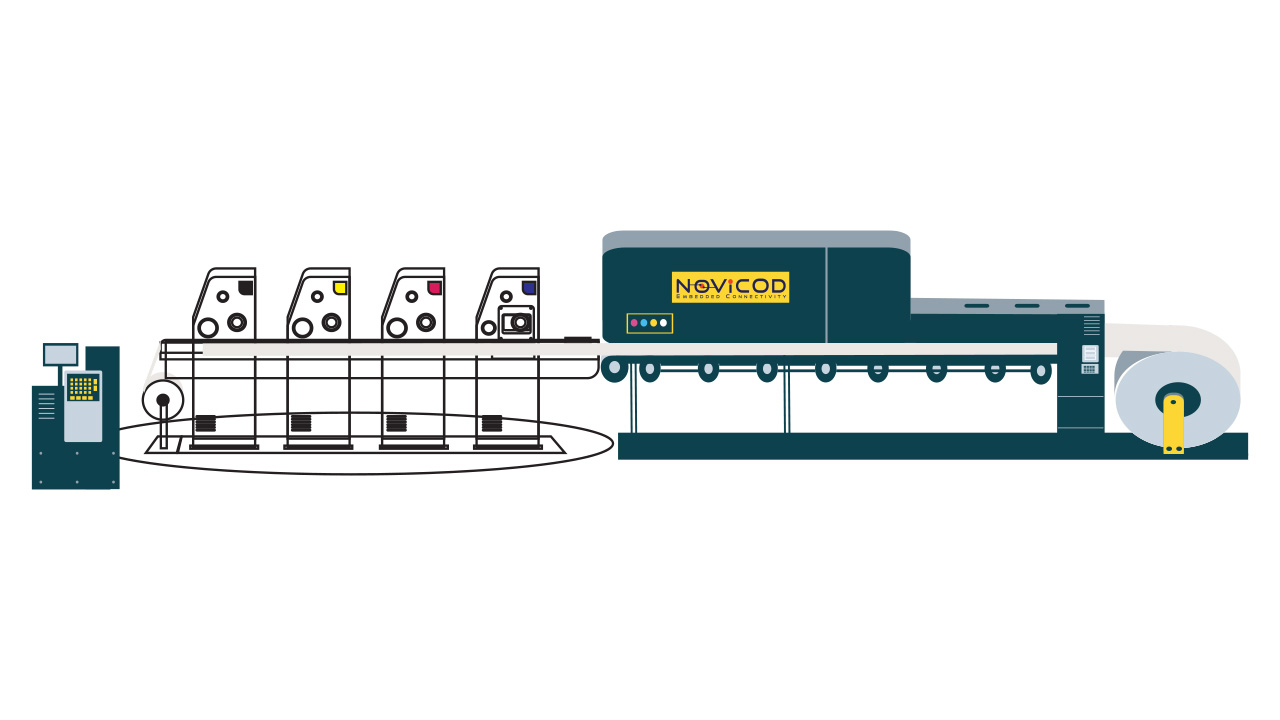

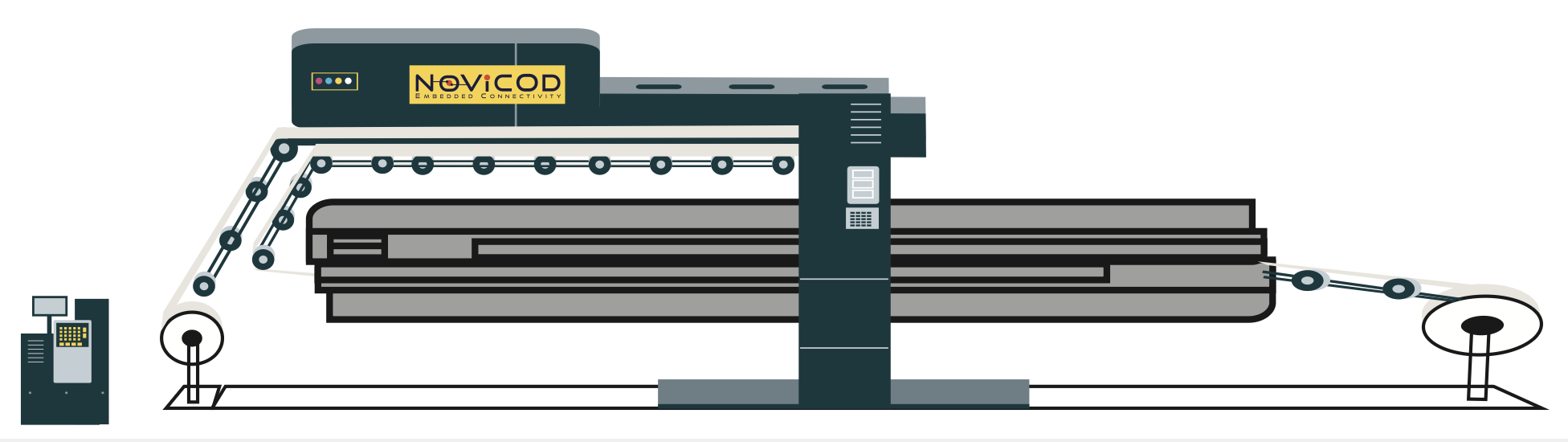

What makes Novicod’s approach revolutionary is how it transforms printing equipment into machines capable of embedding RF technology. Rather than developing standalone machinery, the company has designed six distinct technology units tailored to integrate with existing systems.

‘Novicod’s technology units are fully designed and patented, and we are actively engaging with printing and converting machine manufacturers to establish partnerships,’ Banaim says. ‘These units are designed for seamless incorporation into existing and new printing and converting machines, including PSA and lamination machines, roll-to-roll printing machines and sheet-fed printing machines.’

These partnerships aim to enable machine manufacturers to install and maintain Novicod’s technology units for packaging and label producers. This approach ensures that the technology becomes a natural extension of industry‑standard production processes rather than a disruptive addition.

Beyond the barcode

Many converters are already investigating or implementing interactive labels.

Traditional RFID and NFC implementations have primarily relied on inlays — pre-manufactured RF tags incorporated into labels or packaging as separate elements. Banaim says this approach creates production inefficiencies, increases material costs and compromises design flexibility and product performance.

“Adding RF smart label sticker to every product was not a realistic or scalable solution: not for brands, manufacturers or the supply chain as a whole”

‘Novicod offers a one-of-a-kind solution that enables converters, packaging and label printers to seamlessly embed RFID, NFC and Bluetooth communicators just as easily as they currently print barcodes,’ Banaim states. ‘Unlike other approaches on the market, Novicod’s technology fully integrates RF communication capabilities into the existing production process, eliminating the need for separate smart labels or additional manufacturing steps.’

This integration means converters and printers can adopt RF technology without modifying manufacturing workflows.

‘The very idea that any packaging and label printing agency can now produce in-line embedded RF communicators opens new possibilities for widespread adoption and innovation of connected products,’ adds Banaim.

The technology behind the revolution

At the core of Novicod’s offering are patented technology units that enable the embedding of RFID, NFC and Bluetooth communicators directly within printing and converting processes.

Packaging and label producers need a Novicod unit integrated into their existing printing or converting machines to implement this technology. Next, they require the Novicod Components Click Supply, which includes tailored conductive paste, microchips and an embedding tool. Finally, basic operator training is needed, though the system is designed for seamless adoption.

The technical innovation involves precisely applying conductive materials and microchips during the standard printing process. The company has developed specialized conductive pastes that work within existing printing systems while maintaining the electrical properties needed for reliable RF communication.

‘Our technology represents years of research and development in materials science and printing process engineering,’ Banaim explains. ‘We’ve had to solve complex challenges related to conductivity, adhesion and durability while ensuring the entire system remains compatible with standard production methods.’

The digitalization of item process

Novicod’s vision extends beyond smart packaging to what Banaim calls ‘The Digitalization Of Item Process’. This concept reflects the company’s mission to integrate RF communication capabilities into printed applications, transforming traditional item identification methods into networking, machine-to-machine and Internet of Things capabilities.

While barcodes and QR codes have served as the primary means of item identification for decades, they have significant limitations. They require line-of-sight scanning, provide only static information and offer no real-time communication capabilities.

‘By enabling mass adoption of in‑line‑embedded RF technology, we are driving a future where packaging and labels become part of the digital ecosystem,’ Banaim explains. ‘This creates a frictionless transition from printed barcodes to fully networked digital identities for every item.’

The approach allows for singular ID assignment to each item, real-time wireless item communication for automating registration, monitoring, tracking, authentication and consumer engagement — all within existing industrial frameworks.

With embedded RF technology, items can actively participate in the digital ecosystem, providing real-time status updates, location data and condition monitoring. This capability opens new possibilities for supply chain visibility, inventory management, anti-counterfeiting and consumer engagement.

Three-level support model

To ensure successful implementation, Novicod has developed a three-level support model aligned with its business vision. The first level involves technology provision through partnerships with leading machine producers to integrate Novicod technology units into printing and converting machines. ‘This ensures that our clients receive efficient, high-performance solutions tailored to their production needs,’ Banaim notes.

The second level is the Click Supply Model, in which Novicod remains the exclusive supplier of customized conductive paste, microchips and embedding tools specifically developed for its technology. This approach ensures quality control and continuous technological advancements.

‘We’ve developed proprietary formulations for our conductive pastes that balance conductivity, durability and printability,’ Banaim explains. ‘These materials are specifically engineered to work within standard printing processes while meeting the electrical requirements for reliable RF communication.’

The third level focuses on physical networking and implementation. ‘Beyond providing the technology and click supply, we support our clients by helping their customers implement RF communication surroundings and item networking,’ Banaim says. ‘This enables end-to-end item communication and seamless data flow, unlocking new item processes automatization and consumer engagement opportunities.’

The future of packaging

If successful, Novicod’s technology could fundamentally reshape smart packaging and interactive labels by making RF communication an integral part of printing and converting processes. Unlike current solutions relying on separate smart label stickers, Novicod’s approach allows packaging and labels to be ‘born digital’.

‘RF communicator provides each package and label with a singular ID. The microchip serial code is an individual ID; there are no two of the same one,’ Banaim explains. ‘During item filling and branding processes, each item receives its first digital data registration, creating a personalized digital ID available for wireless networking and real-time communication.’

This unique identification capability addresses a critical supply chain management and authentication challenge. While barcodes and QR codes can be easily duplicated or counterfeited, he says, embedded RF technology with individual serial codes creates a secure digital signature.

“This shift is not just an upgrade; it’s a fundamental transformation in how physical products interact with digital networks and IT surroundings”

In an implemented RF environment, each item is connected 24/7 with memory capabilities for further status updates. This constant connectivity enables real-time tracking, condition monitoring and data collection throughout the product lifecycle.

To scale its technology and accelerate industry adoption, Novicod’s strategy includes expanding partnerships with leading machine producers, broadening its Click Supply model and supporting brands and their partners to benefit from digital RF networking and automatization.

Industry call to action

As a startup that has developed technology that ‘competes with the barcode in the same production machines’, Novicod is actively reaching out to innovative packaging and label printers, converters and machine and finishing equipment producers to join what Banaim calls the ‘global movement’.

With supply chains under increasing pressure to improve visibility, traceability and efficiency, the demand for smart packaging continues to grow. At the same time, brands seek more sophisticated ways to engage consumers, verify authenticity and demonstrate sustainability commitments.

‘We invite brand owners, retailers and logistics companies to take an active role in shaping this transformation,’ Banaim states. ‘This collaborative approach recognizes that widespread adoption requires participation from all supply chain segments, from manufacturing to retail.’

The company has already begun pilot programs with several packaging producers and brand owners across Europe and North America. These early implementations demonstrate the practical benefits of embedded RF technology in real-world applications.

‘The feedback from our early adopters has been extremely positive,’ Banaim shares. ‘They’re seeing reductions in production time compared to traditional smart label applications while also experiencing improved read reliability and greater design flexibility.’

Banaim believes that the technological breakthrough that Novicod represents isn’t just about smart labels; it’s about reimagining the foundation of how physical products interact with the digital world. By embedding connectivity at the press rather than adding it afterward, he says Novicod may have found the missing piece that allows smart packaging to achieve its long-promised ubiquity in everyday lives.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.