Label it with soul

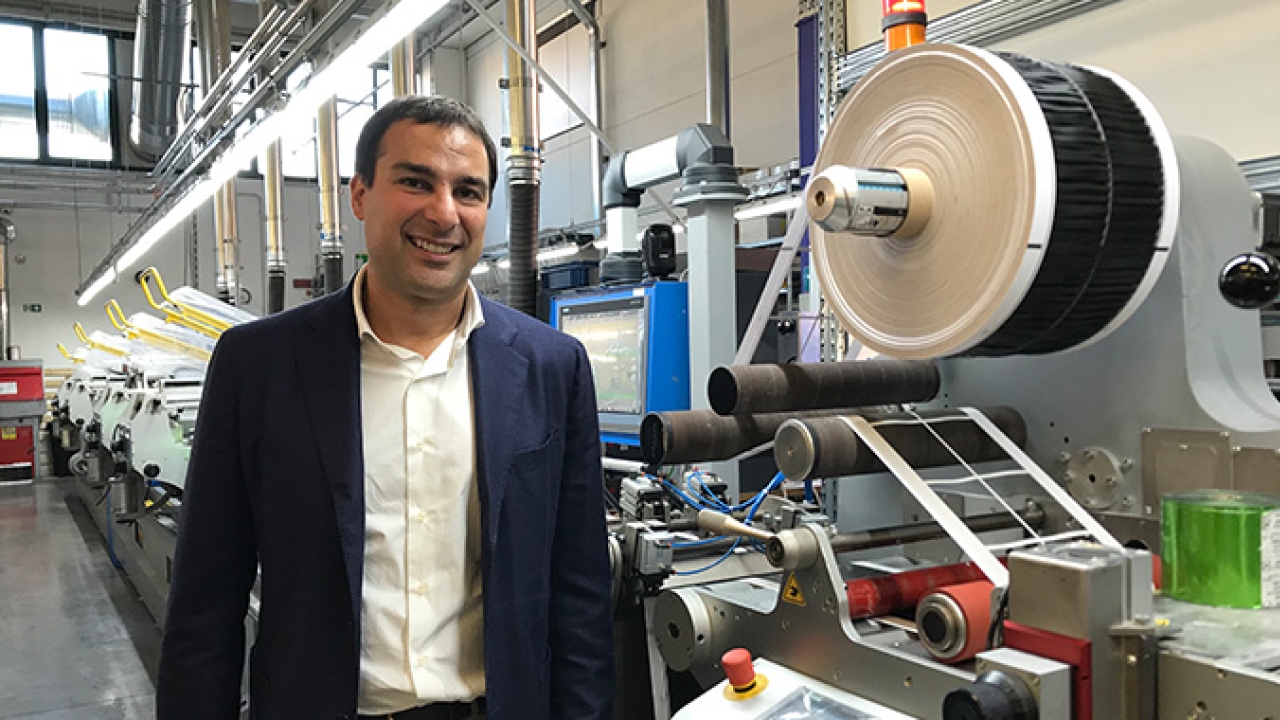

Based just outside Venice, Labelit was founded in 1990 under the name Etichettificio Salese. It printed labels for cosmetics products, soaps, shampoos, and sweets – particularly the Perfetti candy brand and Mentos mints – before being bought by current president Marcello Busetto and renamed.

Three years ago, Busetto shifted the company’s focus onto the food and beverage market, particularly high-quality labels for wine, but also spirits, tomato sauces and jams. ‘This switch in focus required more quality and new technology,’ he says.

A crucial part of the shift in strategy, according to Busetto, was the purchase of a Cartes GT360 converting line, which was brought in to replace an older Franchini machine.

The converting line has a configuration which allows for the most advanced finishing effects, according Cartes’ international sales manager Luca Goldoni. It features a flexo unit followed by three screen units, hot stamping, a further screen unit and semi-rotary die-cutting.

‘We believe in Italian brands,’ says Letizia Gambon, head of sales at Labelit. ‘We undertook a great deal of testing. We knew what we wanted to be able to offer the market, and we found it in the Cartes GT360 converting machine. It is one of the busiest machines we run at the company. It usually operates for 18 hours every day, but sometimes even a full three shifts.’

‘It has allowed us to enter high quality markets. The Cartes machine produces labels with soul.’

Added value

Luca Goldoni says Cartes is seeing increased demand for multiple screen units – which provide enriched embellishing effects – on the converting lines it is supplying to customers worldwide. ‘For wine label printing in particular, the extra screen units can allow the converter to produce jobs with a great deal of added value that helps the products stand out on the supermarket shelf,’ he says.

This has certainly been the case for Labelit. ‘We are looking to differentiate ourselves within the wine label printing market in Italy,’ says Marcello Busetto, whose company has been working with Italian graphic design agency Baseggio Pubblicità on some of its more illustrious creations. He cites tactile effects and Braille as two examples of added value enabled by the Cartes machine. ‘The effects produced by the screen units have opened doors into new, high-quality markets.’

One example is shrink sleeves for wine – a new and growing trend. Labelit’s experience with shrink sleeves – it prints them on two Omet XFlex flexo presses – coupled with the added value opportunities brought by the Cartes converting line, has allowed it to move successfully into this market. The sleeves are printed by flexo and then overprinted on the Cartes system to add screen printing effects and varnishing.

Alongside the Omet machines, Labelit houses three Gallus TCS offset presses and three Nilpeter MO offset presses – equipped with offset, flexo, rotary screen and Pantec hot foil units – at its 3,000sqm factory, with employs a staff of 70 running two shifts.

A Xeikon 3030, upgraded three years ago, adds short run digital printing capabilities. ‘We wanted to be able to offer the digital option to our clients,’ says Busetto. ‘But our focus is more on our conventional printing systems for their added-value possibilities and converting options.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.