Labelexpo Europe 2025: Press technology

Automation, digital integration and the first signs of AI’s potential to revolutionize label production were key features of the show.

Labelexpo Europe 2025 was, in many ways, a landmark show for conventional and digital print technologies.

We saw a demonstration of what AI-driven press automation looks like on the Brotech FF-X530 press, launched at the show, which was developed in partnership with AVT and X-Rite. On-press cameras and spectrophotometers feed data to an AI system, combined with sensors monitoring a range of production factors including ink viscosity, temperature, substrate variations and environmental conditions.

The AI system then makes real-time adjustments to maintain color consistency while reducing setup time and minimizing material waste and downtime.

Ramon Lee, Brotech managing director, explains: ‘Our team has been working for almost two years to integrate AI into conventional flexo printing, with the belief that data-driven intelligence can transform print operations just as digitization once did for digital printing, such as Indigo. This technology is not going to replace people, but empower people to make production easier, greener, faster and smarter.’

We saw other flexo press manufacturers demonstrate real-time data exchange with a cloud-based processing hub. Real-time and historical data are then used to optimize the press setup for the next time the job is run.

Omet, for example, demonstrated its Sfera software for real-time production analytics. Parameters available for analysis include power consumption, waste, ink consumption, press utilization and overall job costing. Sfera is part of a suite of modules including Nova for virtual remote assistance, Gaia for ‘AI-integrated machine management’ and the Tasker workflow automation system.

Nilpeter also demonstrated its ‘Digital Shadow’ system, first unveiled at Labelexpo Americas in Chicago last year, which provides real-time modeling of the press during setups and throughout the print run.

Flexo launches

Demonstrating the vibrant state of modern flexo technology, Omet, Lombardi and Multitec launched new presses at the show.

Omet launched its KFlex K6 sleeve-based modular press platform, featuring the Switch system for rapid exchange of print, coating and converting modules. The flexo groups are directly driven with automated register and printing pressure.

Also new at the show was a sleeve-based offset module that allows for rapid change between repeat lengths. The unit incorporates four inking rolls in contact with the plate and five servo-driven oscillating rolls for improved ink grinding.

Other interchangeable K6 units include a rotary screen, an ECDC die-cutting module, and a cassette-style die-cutting/embossing unit.

The K6 incorporates Omet’s new Multivision camera technology, which only requires a 6mm strip down one side of the web for color-to-color reading.

Available in 430mm and 520mm widths, the press operates at up to 200m/min on a substrate range down to 12-micron film.

Lombardi launched the latest version of its Synchroline flexo press, now rebadged as the Viper, with a smart new look and redesigned for easier operator access. ‘We have simplified processes for the operator for more of a B2C than a B2B experience,’ says Nicola Lombardi, marketing manager at Lombardi.

The press is available in widths from 350mm to 620mm and accepts the full range of Synchroline modules, including cold and hot foil, embossing, rotary and flatbed screen, semi-rotary die-cutting and sheeting.

Also on the stand was an Invicta i1 530 optimized for flexible packaging, which is an increasingly important growth area for Lombardi. An 800mm-wide Invicta was sold to a Taiwanese converter for flexible packaging, with two more flexpack-configured presses going to Vietnam.

“Data-driven intelligence can transform print operations just as digitization once did for digital printing”

Multitec launched its sleeve-based S3S press, incorporating chilled impression and anilox cylinders, to allow printing on filmic materials as thin as 10 microns. Automation features include on-the-fly pre-registration, dynamic print pressure adjustment and register stability during acceleration and deceleration. The S3S press is available in web widths of 450mm to 670mm.

The press at Labelexpo Europe was equipped with six LED-UV curing stations and two conventional UV curing units, still required for coatings. The press was demonstrated changing between a variety of substrates, including 12-micron PET, 35-micron BOPP and PS stocks. The average setup waste between jobs when using a fixed color palette was just 5 meters.

Amit Anhuja, managing director of Multitec, says the S3S press addresses the growing market for in-line flexible packaging production. ‘This year, half of our press production is already going to flexible packaging.’

Flexo automation

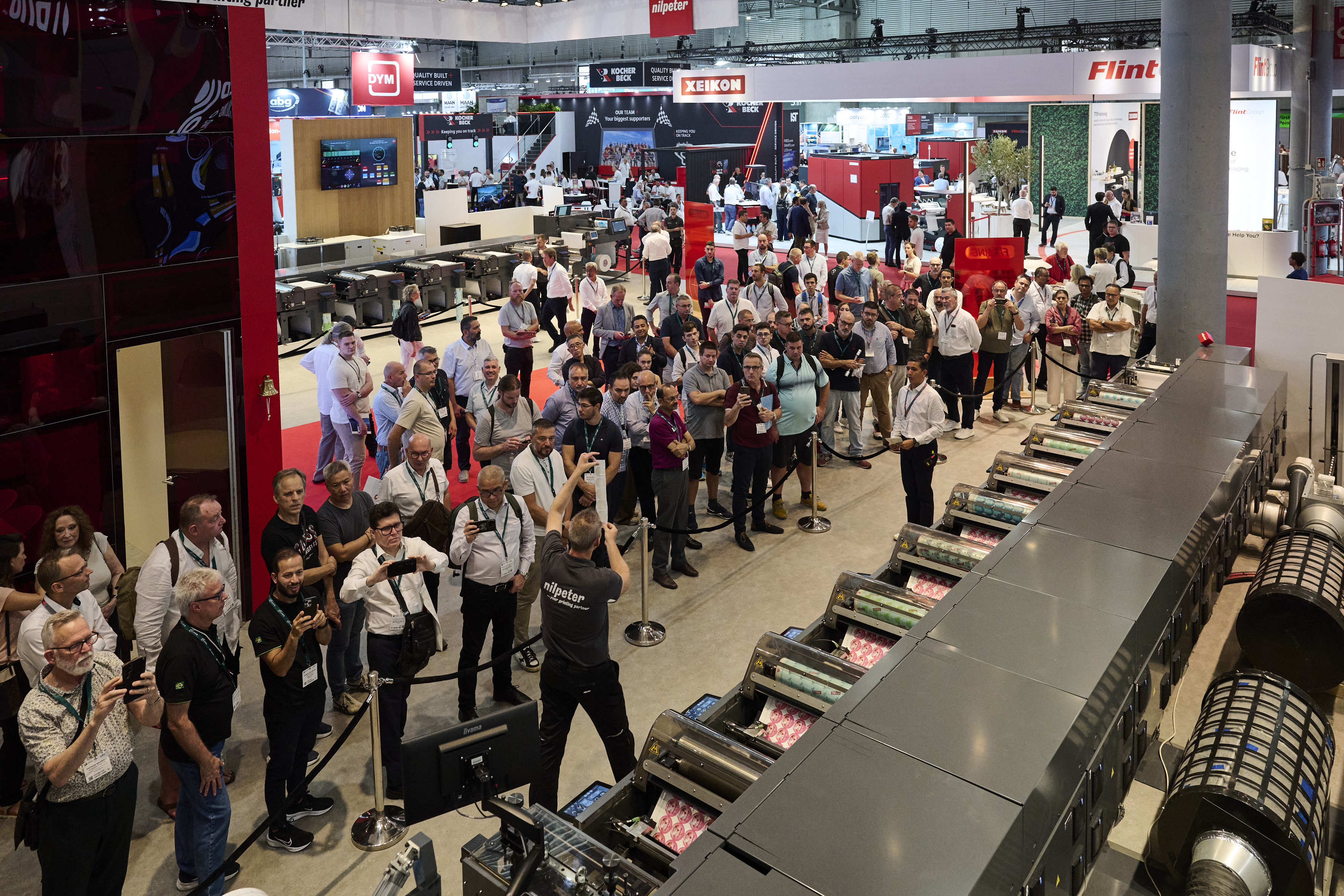

Nilpeter nailed its colors firmly to the flexo mast with its ‘The Future is Flexo’ theme. The company showed two presses, an FA-17 and FA-26, both with full automation packages and integrated into Nilpeter’s expanding ‘Digital Shadow’ Cloud network – itself a part of Nilpeter’s Project Darkroom, which has the final goal of fully automating the flexo printing process.

The 9-color FA-17 was demonstrating a non-stop changeover between two 4-color jobs while the press was running and with just a few meters of waste, as previewed exclusively in the last edition of Labels & Labeling magazine.

‘The change-on-the-fly system offers full flexibility, meaning that it could also be changing between two 6-color jobs on a 12 unit press,’ says Nilpeter CTO Carsten Clemensen. ‘It is also possible to add a second die-cutting unit to change both die-cut and color stations between jobs.’ Aniloxes and ink chambers can be changed on the fly for faster makereadies.

With the biggest stand at Labelexpo Europe 2025, Spande demonstrated its full press program. This included an AC-series press (see the ‘mid-web’ section below) and an 8-color 450mm-wide S7, featuring automatic pressure setting and registration, dual die-cutting units and combined LED-UV and hot air-drying. The press was sold to Hyderabad-based Citrus Innovations.

A 12-color Spande S5 press was also demonstrated along with a hybrid press developed with GIP).

Hontec had a very successful show, selling five FlexiCon flexo presses. Available in web widths up to 570mm and featuring dual servos per print unit, the FlexiCon prints at up to 150m/min.

“The K6 incorporates Omet’s new Multivision camera technology, which only requires a 6mm strip down one side of the web for color-to-color reading”

CEO Leo Zhang shares that flexible packaging will be a key focus going forward. ‘This will include more information on flexible packaging materials and laminations, coatings and anilox choice to teach our label customers how to work effectively in the flexible packaging market. These customers are now facing intense price competition in labels and can find more profitable markets in short-run flexibles.’

Zhang identifies a sweet spot for label converters between 70 and 500kg. ‘That is the gap between digital and CI where it makes sense to invest in an in-line flexo press.’

Weigang showed its ZJR 350G flexo press, which converts a wide range of substrates from 12 microns to 400gsm, including shrink sleeves and IML. The company reported overseas revenue growth of nearly 40 percent year-on-year in 2024, with plans to build global technical service centers starting in 2026 to provide 24-hour customer response.

Other Chinese flexo press manufacturers included Dowell Europe, which demonstrated its SF-series press printing at up to 200m/min.

First-time exhibitor Qianrun showcased the new servo-driven Label King S5-370-8C in-line flexo press with automated print pressure and inking pressure setting.

Label Source demonstrated non-stop production with its F6-370-10C flexo press, featuring non-stop unwind and rewind, and non-stop matrix waste removal.

Zonten showed its ZTR in-line flexo press configured with cold foil and LED-UV curing. The press includes intelligent job presetting, remote diagnostics support, automated register control and adaptive tension control.

Hongshen showed its SFLEX-450 flexo press and secured a deal with Spanish converter GSP Etiquetas on the first day – the company’s second HS flexo press.

Semi-rotary flexo is a niche technology that offers short-run capabilities as an alternative to digital, while retaining existing flexo tooling and workflows.

Rhyguan launched its first flexo press at the show, capable of switching between semi-rotary and full rotary modes. The Rhyguan RF 330 builds on the company’s expertise in developing standalone semi-rotary finishing systems and prints at up to 180m/min in full rotary mode and 60m/min in semi-rotary mode on a 330mm-wide web.

Caisheng showcased its CS-J380F semi-rotary flexo press.

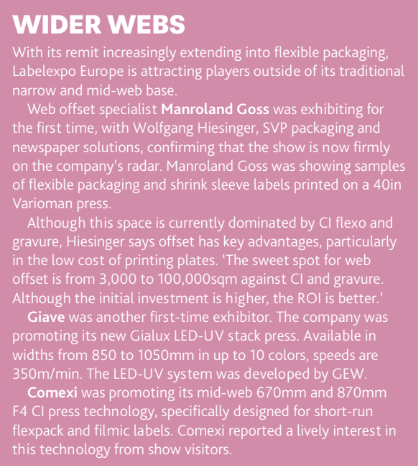

Mid-web flexo

Labelexpo Europe 2025 demonstrated the continued rise of the mid-web flexo press, with machines in the 670-850mm width range. Spande demonstrated an 8-color 800mm-wide AC series press operating at speeds up to 250m/min. Each flexo printing station incorporates nine servo motors and handles substrates ranging from 12 to 800 microns. The AC series supports both roll-to-roll and roll-to-final-package workflows, with modular in-line finishing technologies that include embossing, creasing, die-cutting, stripping, inspection, sorting and stacking.

“The 9-color FA-17 was demonstrating a non-stop changeover between two 4-color jobs while the press was running and with just a few meters of waste”

Mark Andy showed its mid-web S9 sleeve press in Europe for the first time. Built on the established Performance Series platform, the press has a comprehensive automation package and was demonstrated communicating via the AVT inspection system with a Rotoflex VLI rewinder.

Mark Andy CEO Duane Pekar points out, ‘Although the press was designed primarily for flexible packaging, it can also print labels at 1,000ft/min with the added flexibility of the rail system. This is important for label converters looking to move into adjacent markets like flexible packaging and looking at investing in a multi-million-dollar machine. The fact that it can also run labels incredibly fast with high productivity allows customers to get into flexible packaging in a low-risk way. This machine will also run cartons.’

Nilpeter showed a 7-color 670mm-wide FA-26 with an advanced automation package. During the roll-to-roll demo, the press ramped up to an extraordinary 400m/min with no operator intervention.

Omet demonstrated an 8-color, 670mm-wide X7, configured with an extended dryer for applying water-based coatings. Rotatek showed a print unit from its redesigned Universal 850 rotary offset press.

MPS demonstrated a new EF Packaging print unit, which extends the company’s EF platform into flexible packaging.

Intermittent offset

Miyakoshi demonstrated an LPS13A semi-rotary offset press with the latest upgrade to its Yaless AI system press monitoring system.

Yaless AI constantly monitors ambient temperature, dampening water conditions and ink temperature and prompts the operator to make manual adjustments. The new Professional upgrade enables the press to make autonomous adjustments to dampening water and color density settings based on the AI model.

Other intermittent offset presses at the show included the Weigang ZX320, Wanjie WJPS-350, Zonten ZTJ and Nickel FS-350.

Hybrid

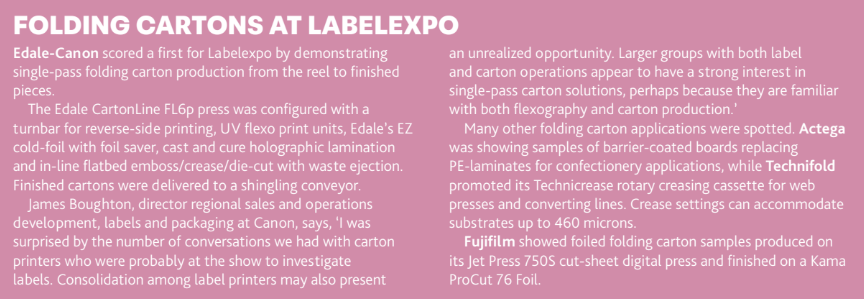

Heidelberg-Gallus continued its strategic move to integrate digital and flexo through its ‘System to Compose’ program with the launch of the Gallus Five.

The Gallus Five offers the same 1,200 DPI resolution as the original Gallus One digital press, but increases production speed to 100m/min. This is achieved by a combination of Heidelberg’s newly developed high-pigmentation Saphira UV05 ink set, optimized LED-UV pinning and curing, and new control software.

The Gallus Five is built on the same frame as the Gallus One in widths of 340mm and 430mm, for full compatibility with the Labelmaster flexo platform. The Gallus One can be retrofitted to the Gallus Five specification.

New to the ‘System to Compose’ is the SDC Pro semi-rotary die-cutter operating at up to 100m/min, allowing rapid job changeovers.

The Gallus Five comes as standard in a 6-color configuration (CMYK+OV), which covers some 95 percent of the Pantone Plus V4 color library. Digital white can be added at full press speed.

Gallus has conducted extensive TCO costings, establishing 10,000 linear meters as the optimum crossover point for the Gallus Five hybrid with conventional printing.

Gallus Group CEO Dario Urbinati stresses that the Gallus Five will not replace the LabelFire hybrid press, which continues to be sold into bespoke applications, including folding cartons.

Durst showcased the KJet hybrid press, which combines the Durst Tau RSCi print engine with flexo and finishing units from Omet’s modular KFlex platform. Going forward, the KJet will incorporate the new Omet K6 sleeve-based modules launched at the show as well as Durst’s new G3 print engine.

Mark Andy demonstrated for the first time in Europe its Digital Series HD High Speed1200 press printing at speeds up to 146m/min. The speed milestone was achieved in partnership with Hybrid Software companies Global Graphics and Meteor Inkjet. Mark Andy’s ProWorx workflow system is powered by the Global Graphics Smart DFE, and streaming real-time raster data is streamed directly to the Meteor printhead electronics.

Lombardi showcased its Digistar 330 hybrid press, showcasing the company’s close cooperation with Screen Europe, which supplies the Truepress Label 350UV SAI S print engine. Comments Nicola Lombardi: ‘I am delighted that Screen has now extended our partnership beyond Italy, allowing the Digistar/Screen hybrid presses to be sold throughout Europe. This allows Lombardi to retrofit existing Screen presses with modular flexo converting equipment from the Digistar platform. This is a major step forward.’

“The fact that it can also run labels incredibly fast with high productivity allows customers to get into flexible packaging in a low-risk way. This machine will also run cartons”

Spande and General Inkjet Printing

displayed the Label Modular 450HD hybrid press on the Spande stand. First seen at Labelexpo South China last December, the press is built on the Spande S7 flexo press platform and can integrate any of those print, decoration and converting modules. The GIP digital engine uses Kyocera heads for a print resolution of 1,200 DPI in eight colors (CMYK+W+ three spot colors) at 75m/min.

HanLabel showed a hybrid press configured with a 1,200 DPI 8-color inkjet engine, four flexo stations with non-stop unwind, rewind and matrix removal. HanLabel is a partnership between HanGlory, which provides the LabStar 330HD digital engine, and Label Source, which provides the modular flexo platform.

Flora showcased its Orca 350 hybrid press, with a CMYK+OVG+W print engine in-line with cold stamping, varnishing and laminating, along with a digital varnish unit. The print engine covers more than 85 percent of the Pantone color gamut.

Digital presses

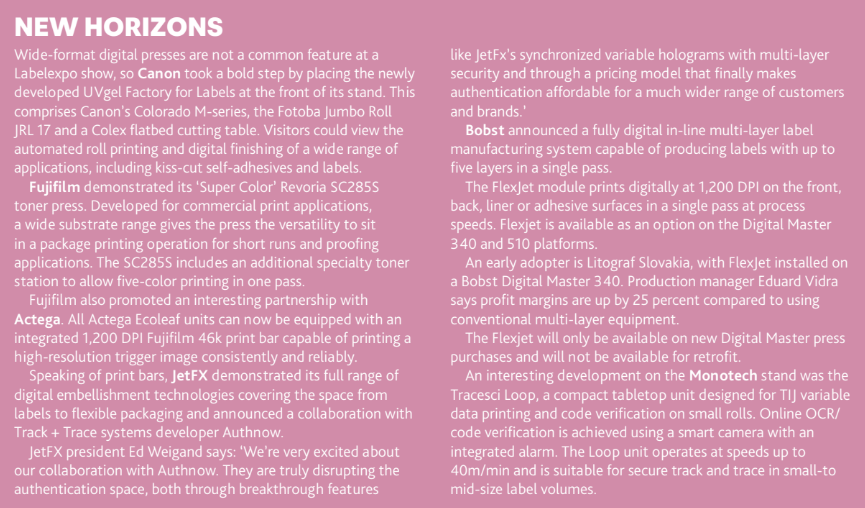

Key digital themes at this Labelexpo included the expansion of the options for water-based inkjet and new entry-level presses, allowing both label and commercial printers a first step into the digital ecosystem.

Water-based inkjet

Labelexpo Europe 2025 saw an upsurge in interest in water-based inkjet for labels. These presses are targeted mainly at the food, beverage and pharma markets where brand owners might be reluctant to use UV, or where low migration UV ink systems are required to reduce odor, often requiring the addition of nitrogen inerting.

Epson initially led the way in water-based inkjet with its hugely successful L-4033 and the successor L-4733.

The company launched its next-generation water-based press, the SurePress L-5034, which greatly increases both productivity and print resolution.

The L-5034 is a 6-color machine (CMYK+OG) equipped with Epson’s PrecisionCore printhead technology delivering 1200 DPI resolution at a speed of 13.5m/min compared to the 5m/min of the L-4033/4733. The six-color print engine, using Epson’s AQ pigmented ink series, covers 90 percent of the Pantone gamut.

A key innovation is the AQ optimizer, applied just ahead of the color, which pins the ink to the substrate, speeds drying and enhances ink adhesion on a wide range of substrates from coated and uncoated papers to films.

Like the L-4733, this is an intermittent-feed design, using a longer table to achieve the higher speed. The web width is 340mm, and the press accommodates up to 120kg rolls.

Marc Tinkler, head of product marketing at Epson Europe, says maximizing uptime was a key development factor, ‘and this is more important than speed.’ Tinkler points to Epson’s proprietary automated real-time nozzle verification technology (NVT), along with nozzle compensation and an automated printhead cleaning system.

Screen is becoming a major powerhouse in the aqueous inkjet sector, not only for commercial and flexible package printing, but also with the launch of a new concept press for the labels market.

The prototype Truepress Label 520AQ uses the same SC+ VOC-free inks and NIR drying technology as the company’s Truepress Jet commercial presses. It makes use of Screen’s

proprietary RIP and substrate control systems, all managed by Equios workflow software.

Screen showcased a partnership with UPM, which has developed a special top coating for the Truepress Label 520AQ to enhance ink adhesion, allowing ‘immediate’ drying at 100m/min at 1200DPI resolution on both paper and films.

UPM has optimized a number of substrates for the press, including polypropylene self-adhesive label face stocks and BOPP films. For paper-based applications, UPM’s Jet Matte paper has a special coating optimized for use with water-based inks.

Screen’s 600 DPI Truepress PAC 520P water-based inkjet press for paper-based flexible packaging was on the stand, and Screen showed samples from its water-based Truepress PAC 830F for flexible packaging films.

Arrow Systems displayed its ArrowJet Bolt Hybrid Pro M press, which uses Memjet Durabolt technology with dual-head redundancy to achieve speeds up to 150m/min with in-line flexopriming and varnishing stations. Also shown was an ArrowJet Aqua 330R printing at speeds up to 45m/min at 1,600 DPI.

UP Group demonstrated its LQ-MD 320HD water-based label press, equipped with Epson I2300-HD printheads with 1,200 DPI resolution printing at speeds up to 48m/min.

Pulisi promoted a water-based flexible packaging press, which the company showed in prototype at Labelexpo South China last year. A production machine is expected to be on stand at Labelexpo Asia 2025 in December.

Arojet is another supplier that promises a digital flexible packaging press at Labelexpo Asia 2025, although using water-cooled LED-UV rather than aqueous inks.

UV inkjet

Durst Group launched its new digital press platform, the Tau G3, initially featuring two press models. The G3 will replace the Tau RSCi model going forward, although the entry-level E-Tau 340 RSC-E will remain.

‘This is the result of extensive feedback obtained from users of the RSCi presses,’ explains Martin Leitner, product manager labels and flexible packaging at Durst. ‘The press is more automated, making tasks easier for the operator, easier to maintain and more efficient. It is an evolution of the RSCi design rather than a revolutionary change.’

The Tau G3 Core and Tau G3 Peak models offer native 1,200 DPI resolution, with speeds reaching 61m/min and 80m/min, respectively. The Peak model can be optionally expanded to 100m/min, depending on the configuration. Print widths range from 244mm to 510mm across both models.

The platform supports CMYK + OVG+W, available with both UV and LED curing. The substrate range is between 20 and 500 microns.

New features include Durst ARC (automatic register control) and Durst MEP (material edge protection), which safeguard printheads with optical edge sensors and protective plates. The optional Durst Hawk AI monitoring system automates color-to-color register and provides closed-loop nozzle correction during printing. A redesigned cooling system and electrical cabinet enhance component accessibility, facilitating simplified handling and maintenance.

The first Tau G3 systems have been in beta testing at customer sites since August. The official market launch is planned for Q2 2026.

Domino launched the N410 LED inkjet press, providing a lower-investment entry point to its established N-series label press technology. The press operates at 30m/min, with a 50m/min high-speed mode, in five colors (CMYK+W) at 600 DPI resolution, capable of hitting 86 percent of the Pantone gamut.

The press is powered by Domino’s new AI-driven Sunrise DFE, also launched at the show. The N410 is supplied with a range of core Sunrise modules, including print cost estimating. The N410 DFE is integrated into the main press frame, allowing for a compact footprint with no external control cabinets.

Heidelberg-Gallus launched the Gallus Alpha standalone digital press targeted at converters looking for a cost-effective entry point into digital printing. The Alpha is 340mm wide and is supplied in two configurations: 4C+ white and 6C+ white, both with a print resolution of 1,200 DPI and printing at 65m/min.

Screen demonstrated a Truepress Label 350UV SAI S UV Inkjet press configured for continuous operation in conjunction with a new finishing line developed by Nilpeter.

The Refine Compact 2 digital finisher can be used in-line or off-line, configured with varnishing and laminating modules. It incorporates automation functions that enable cutting and varnishing stages to be aligned with upstream print data.

Dantex showed upgrades to its PicoJet digital press. The Dynamic Resolution System (DRS) now offers eight gray levels, allowing for improved resolution, finer halftones and smoother tonal transitions, along with a new ‘small dot’ technology to further increase print definition.

The company demonstrated the GM DC350 Mini Finisher, which combines rotary flexo, semi-rotary die-cutting, lamination, cold foil, waste matrix removal, cutting and slitting in the same unit. The new PicoEngine DFE was developed in collaboration with Global Graphics’ Smart DFE, integrated with a new-look PicoPilot press operating system.

Dantex also launched a new series of high-viscosity UV inks, anticipating the CMR and SVHC regulations effective from 2027.

“Xeikon sees the TX300 press substituting UV inkjet in a range of applications where food safety and durability are required”

Weigang launched two UV inkjet presses at Labelexpo. The WG S350 Ultra prints at 1,200 DPI using Kyocera KJ4A printheads at up to 75m/min on a print width of 310mm. The press comes as standard with CMYK+W, with optional spot color and digital varnish stations. The press has LED-UV pinning and arc UV final cure.

The entry-level WG S230 prints at 60m/min at 600 DPI native using Epson S3200 printheads on a 230mm print width. The press ships with CMYK+W, with varnish and spot colors available as optional extras.

Pulisi showcased two Aobead digital presses with 1,200 DPI print resolution.

First-time exhibitor General Inkjet Printing

demonstrated its Label Smart UV inkjet press in a CMYK + double white configuration. It showed the Label Ultra digital press featuring an upgraded 1,200 DPI printhead.

UP group showcased a 6-color UV inkjet press with integrated digital varnishing and foiling capabilities.

Jetron demonstrated its D2Roll LB3550 UV inkjet press configured with digital embossing and opaque white, driven by the company’s Saga Lite workflow. New was Jetron’s PB400 printbar, offering speeds up to 75m/min, both with printing and digital embossing capability.

Toner technologies

HP launched the HP Indigo 6k+, which integrates the new SmartControlSystem with AI-driven workflow tools and diagnostic systems that greatly increase press productivity.

Ireland-based Watershed Group was a beta site for the new press and confirmed an order for a second machine at Labelexpo Europe. Company director Kirwan Waters says, ‘The press has strengthened our lead times, improved on-time delivery, and given us the flexibility to shift shorter runs to digital, freeing up capacity across the business.’

HP announced multiple sales of the 6k+ at the show, including two to UK-based Baker Labels and one to Nordic-based Boxes&Labels.

The SmartControlSystem requires significant software and hardware upgrades, meaning it is not retrofittable to existing 6K presses.

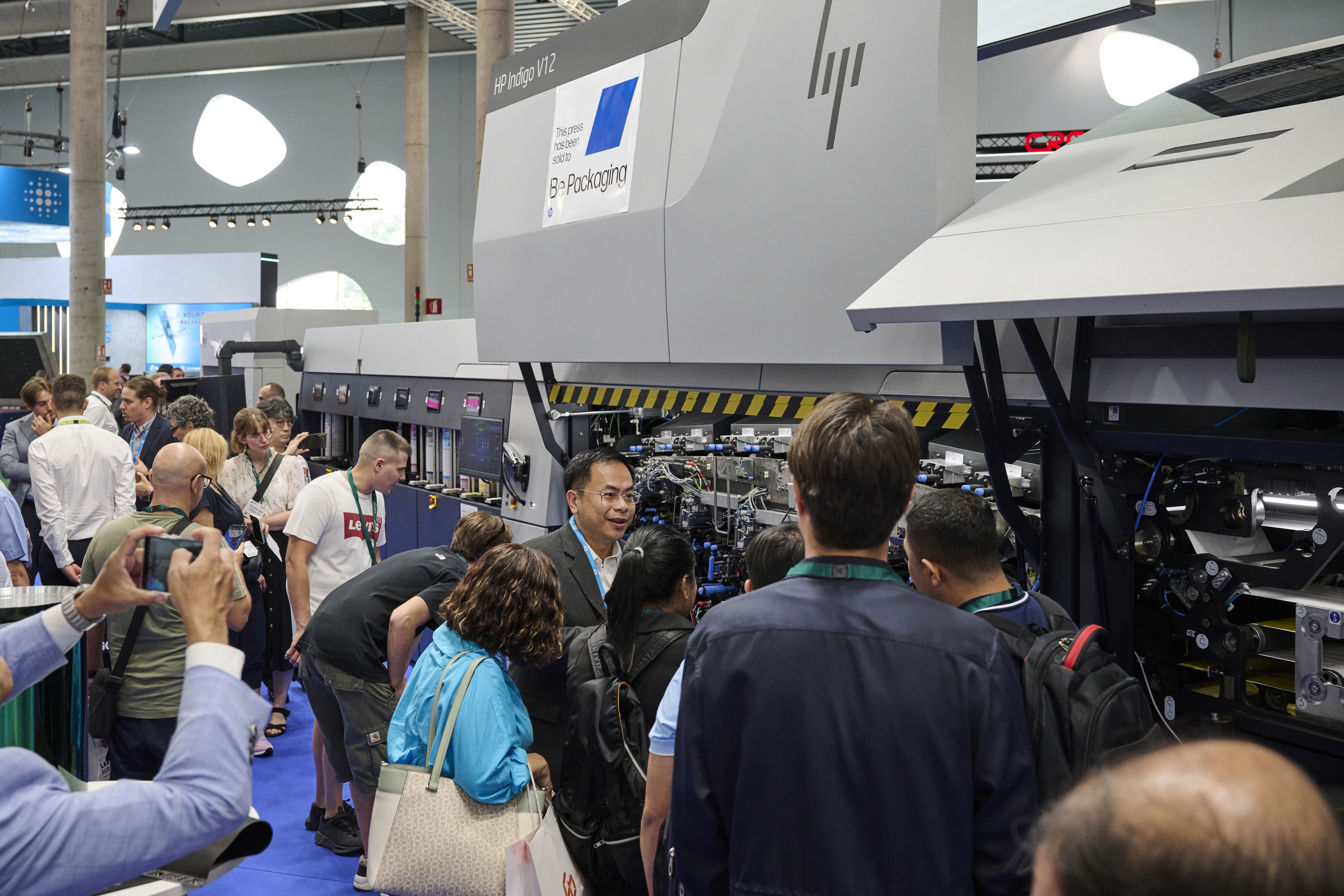

Joining the 6K+ press on the stand was an HP Indigo V12 Digital Press operating at 120m/min, incorporating ABG non-stop unwind and rewind. Sales of the V12 announced at the show included European converters Be Packaging and Labelisten.

Two sales of the 200K press were announced at the show to Digital Etikett and ePac Europe.

HP also announced an expanded portfolio of in-line primers, the result of new collaborations with Actega, Sun Chemical, and established partner Michelman.

Xeikon launched the TX300 toner press, bringing the company’s Titon toner technology to the wider labels sector.

Titon integrates a specially engineered dry toner with a low concentration solid initiator. A final in-line LED-UV curing station cross-links the polyester-based toner particles to form the extremely tough toner layer. Titan toner is food-safe, heat-resistant – designed to withstand pack sealing temperatures up to 260 deg C – resistant to scuffing and scratching, water, sunlight and solvents without requiring a protective varnish or lamination.

Titon toners are approved for both coated and uncoated papers and PP facestocks and do not impact recyclability.

Xeikon sees the TX300 press substituting UV inkjet in a range of applications where food safety and durability are required. The Titon toner delivers a matte finish, as opposed to UV inkjet’s inherent gloss, often preferred for premium food and beverage packaging applications.

The TX300 press prints at speed up to 30m/min.

Xeikon also demonstrated a PX3300HD inkjet press integrated with a label converting unit (LCU), allowing a single operator to produce finished labels in a single pass. This signals a new strategic approach from Xeikon to offer fully integrated label production lines from the X-800 DFE through to finishing.

This PX3300HD prints at 1,200 DPI resolution in five colors (CMYK+W) on a print width of 348mm. Xeikon’s PX-Cure LED HD inks allow up to 88 percent of Pantone colors to be printed to deltaE2, or 94 percent at deltaE3. Printing speed is 70m/min in five colors. The press incorporates an in-line camera scanner, verifying registration and with missing nozzle correction.

Konica Minolta showed a prototype successor to its hugely successful AccurioLabel 230 toner press. The prototype press prints at the same speed of 23.4m/min but has an increased print resolution of 1,200 x 2,400 DPI.

A new option is the Intelligent Quality Optimizer (IQ), previously seen only on the top-of-the-range AL400. The IQ system delivers a boost in productivity by automating workflows, maintaining color registration and enabling longer print runs up to 1,600 linear meters. No date has yet been given for commercial availability.

Mark Andy is already looking at integrating the new engine into its Digital Pro press.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.