Narrow web for flexible carton board production

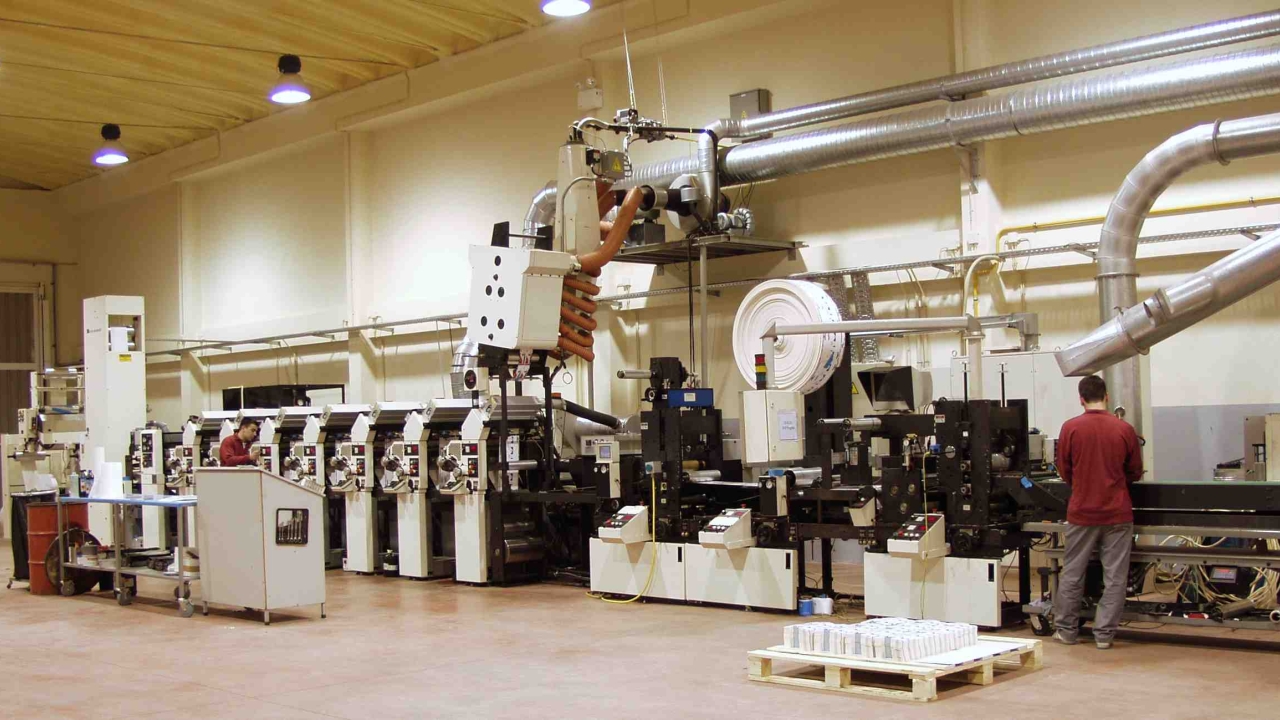

Portuguese label and cardboard box manufacturer, Olegário Fernandes, is one of the country’s leading converters of carton boxes for the pharmaceutical industry, using inline flexo printing machines and rotary tooling in response to a rising demand for reduced delivery times and shorter production runs.

Having seen the potential, Duarte Sousa, managing director at Olegário Fernandes commented: ‘We planned how to work smarter – to be more flexible, with shorter production runs and lower costs because we knew that the demand could not be met by traditional sheet fed offset production.’

The installation of a Comco ProGlide MSP in 2003 allowed Sousa to produce folding cartons with rotary die cutting. This reduced the workflow to one process compared with two – sheet-fed printing and flat bed die cutting, and offered several advantages: more uptime, and the ability to handle shorter production runs and lower production costs. But, the cost of solid rotary die tooling, and its lack of flexibility, have proved a challenge.

The solution came in the form of Gerhardt flexible male/female dies mounted onto magnetic cylinders, who responded at short notice. ‘I’m impressed by their ability to deliver such complex and high precision tooling within 72 hours from their factory in the UK,’ he said. ‘Previously, delivery was two weeks for a new set of male/female flexible dies. Now, we can turn jobs at very short notice.’

The Comco produces finished cartons in a single pass at speeds of 80 m/min, and is operated by only one press minder. Sousa estimates that a set of male/female flexi dies offer at least 7 million cartons, or the equivalent of 2.3 million revolutions.

Current box production is with 0.5mm board, but the Comco is capable of handling up to 0.6mm, and included in this process is the obligatory embossing of Braille dot text for the visually impaired.

Production at the plant is fully automated and runs 24-hours a day, which equates to four million cartons per month. It is an all-in-one process where the cardboard is printed, creased and cut in only one pass. The flexo process allows easy and accurate color adjustment, which is demanded by the brand owners in the pharmaceutical industry. In addition, wastage from test runs can be minimised with this set-up. Downtime is considerably lower, and the set-up of the male/female flexible dies, which needs only one operator, takes only 15 minutes. This is vital when run lengths are down to 5,000 cartons, or fewer.

Olegário Fernandes employs 100 people in its factory in Massama, 20km outside the Portuguese capital, Lisbon, and is a primarily involved in the production of folding cartons (and labels) for the pharmaceutical, food & beverage, personal care and cosmetic markets. Among its customers are: Colgate, Unilever, Bayer, Janssen-Cilag and OM Pharma.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.