The past, the present and the future of ArtiosCAD

ArtiosCAD, Esko’s flagship packaging structural design software, celebrated its 15th birthday in 2013, and David Pittman spoke to the man currently responsible for the system about the past, the present and the future of the software.

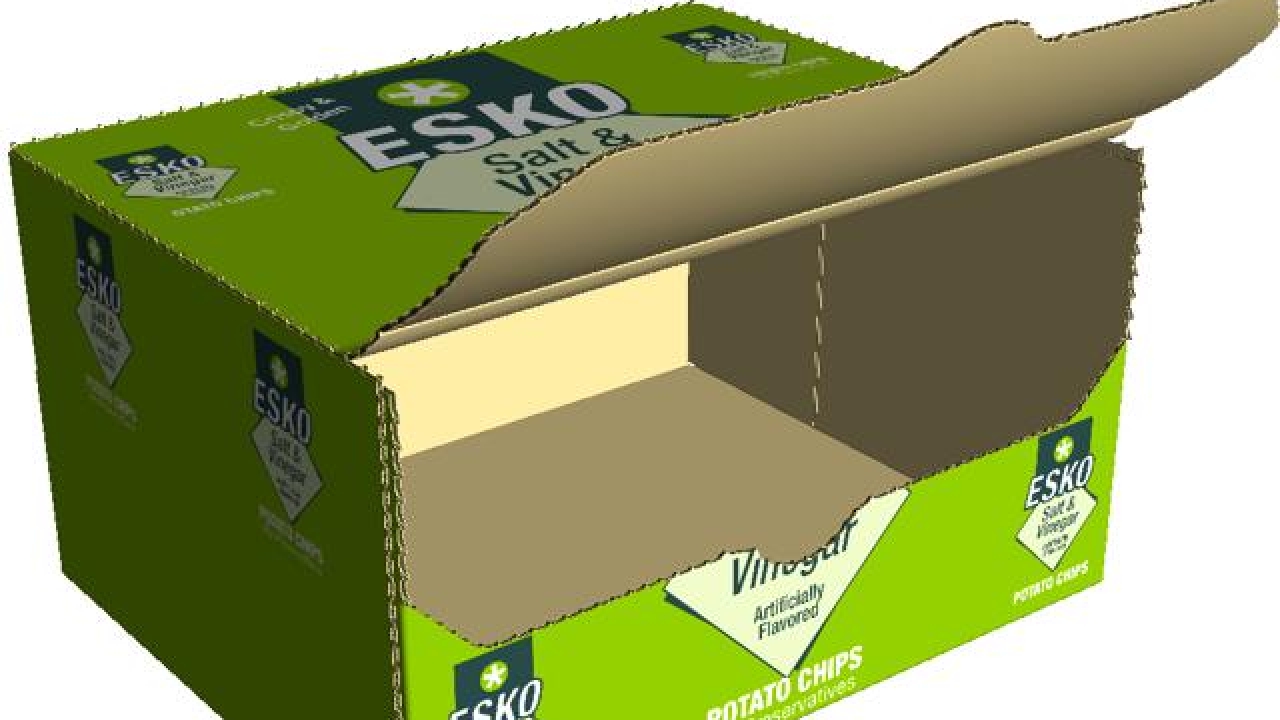

ArtiosCAD is recognized around the world as the leading structural design software for the packaging market, with tools dedicated specifically for design, product development, virtual prototyping and manufacturing, and is well suited for use in the folding carton and corrugated markets, as well as the creation of POP, POS and FSDU displays.

ArtiosCAD is one of Esko’s core products and is seen as essential to the company’s plans to help connect various stakeholders up and down the packaging supply chain, whether directly or through functions of the software that have found their way into other Esko products.

Its roots were laid in the UK during the late 1970s when Simon James and friends founded Lasercomb. This enterprise focused heavily on CAD/CAM work in the folding carton market, as well as dealing with tooling and plate making, and led to the establishment of Lasercmb Americas.

It was during this phase that James and the Lasercomb team decided to focus on their software activities, and spun out their tooling operations.

Lasercomb and its software eventually become part of the Esko family via acquisition by Barco Graphics and Esko.

Esko’s structural design product manager Richard Deroo says it was this heritage that helped the ArtiosCAD software become so well established in the packaging sector.

‘Their experience in tooling meant that they had a rounded knowledge of pre-press production, as well as existing contact with the market and potential customers.'

Since the introduction of ArtiosCAD in the late 1990s, the biggest change in the market, in Deroo’s eyes, is the use of 3D in packaging design.

‘When ArtiosCAD first entered the market, there was no 3D; all design was done in two dimensions.

‘Now, 3D is the industry standard, as it has made the design process faster and more intuitive; production assets are automatically created and are used throughout the pre-press and production process by relevant people and systems.’

A recent release of the software was ArtiosCAD Enterprise, where all assets are stored in a centralized – yet private – corporate database in the cloud.

It enables dynamic online collaboration between design groups, CAD and graphic designers, suppliers, brand owners and production.

‘Our customers want all their processes to work seamlessly through multiple stakeholders but through a central point of contact,’ says Deroo.

‘With ArtiosCAD Enterprise, multiple stakeholders can be involved in the same project without duplication of information, and in a timely manner, allowing central assets to be changed and all to be made aware of the changes.’

This collaboration trend extends beyond stakeholders to the software itself, which must increasingly be able to freely work and communicate with third-party applications, such as MIS and ERP tools.

‘This information is often important to each step in the process so needs to be passed along, but we also need to reduce the risk of duplication and human input error, so software integration serves a valuable purpose.’

Deroo says this is one of the main functions being asked of Esko and its products by customers. Esko receives feedback on what the next versions of ArtiosCAD should include from its global user base through events such as EskoWorld, its user conference. The 2013 event was its biggest to date, and Deroo notes that there are more than 14,000 licenses worldwide, so, ‘there’s no shortage of requests on the wish list.

‘Our customers are asking us to help them do more and increase productivity, with integration central to this, and we’re working on ways to seamlessly integrate all their operations and collaborate globally.’

Read more features from Packprint World here

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.