Sustainable substrates: Hemp

While hemp may have gained some traction in the last few years, this is not a new material by any means. According to the Hemp Foundation, ‘The first known use of hemp paper was in China way back in 200-150 BC.’ While it fell out of favor due to government bans, the benefits of this material never faded. Compared to trees, hemp has a remarkably short growing cycle, as Hemp Foundation details: ‘Hemp is ready to harvest in about 70 to 90 days from the time of seeding as compared to most trees which take around 20 to 30 years to completely mature.’

Additionally, hemp requires far less space. ‘The number of sheets of paper produced from around 4,000 square meters of hemp is equal to what trees over an area of 40,000 square meters can produce for twenty years,’ explains Hemp Foundation. For end of life, hemp paper ‘is far more recyclable compared to other papers. Wood paper can be recycled to the maximum of three times; however, hemp paper can be reused around seven times.’

The structural makeup of hemp also makes it as advantageous as paper. As Hempathy Living explains, hemp has a higher cellulose content and a lower lignin content than wood; this is an advantage because in processing paper, lignin must be removed and a higher cellulose content is more desirable. Additionally, hemp paper is much stronger than tree paper: three times stronger according to the Global Hemp Association. In addition to being more recyclable, OG Hemp found that hemp fiber can be totally composted in 60 days.

Paper making company Mohawk explained that turning hemp into pulp ‘requires less chemicals, water, and energy than wood, and it can be used to make a vast array of paper types, from greeting cards to label paper, cardstock, and packaging.’

An added bonus of hemp paper is that it utilizes what was previously wasted. ‘Previously hemp stalks never got utilized, other than being tilled under out on the fields,’ Mohawk detailed. ‘Now, they can be repurposed to make paper that’s a benefit to the environment on every level.’

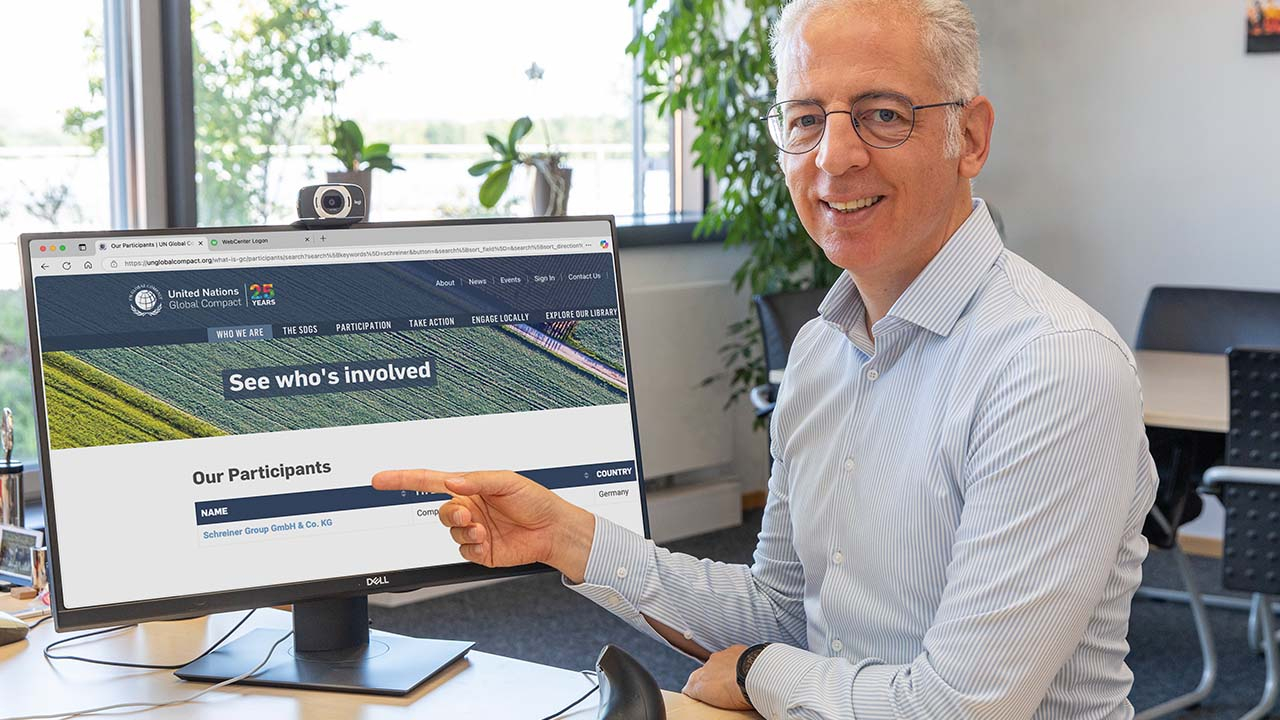

Global Hemp Association

To learn more about the benefits of hemp L&L spoke to Mandi Kerr of Global Hemp Association. Kerr emphasizes the sustainability benefits of growing hemp, regardless of end use markets. ‘Before the paper even, the plant itself is sequestering an astronomical amount of carbon. What it is capable of doing for our earth to eliminate or substitute the deforestation is really peaking people’s interest. It grows four times the biomass per acre of hemp compared to an acre of trees and hemp grows in 120 days compared to 20 years for a tree,’ says Kerr.

‘Another great benefit of hemp is what it does to the soil before its processed. It has a large tap root, up to 9-12 feet, so imagine what that does to a compacted soil and what that does for runoff prevention. That leads to reduction of water waste, better nutrients, holding on to carbon within the soil, increased microbes, and with all that comes increased crop yields.’

However, mainstream hemp paper and other hemp-derived products are held back by the current limited supply. ‘When we talk about growth of the industry, we are up against input limits. I can go build a big paper mill and there are trees available, the input is there. The input doesn’t exist on the market currently for hemp.’

She continues, ‘Hemp is growing in very small volumes currently and the volume we would need to support a printing press is potentially millions of acres. We are looking at larger volumes and there are other countries that have led the charge in the development of hemp because they were able to study it this whole time. But they are still small scale. Europe, for example, is supplying the majority of the processing equipment but Europe's size and volume at which they will produce is miniscule compared to the United States, so that is our next obstacle. But hemp is definitely growing, there are seed plots everywhere and test plots on what fiber to grow where. And there is a lot of lifecycle analysis happening to prove that carbon footprint and that carbon footprint is what brings hemp to the forefront of the discussion now.’

Current market offerings

Despite these input limitations, there are already several hemp paper options on the market. Greenfield Paper offers a hemp paper that is 25 percent hemp and 75 percent post-consumer recycled waste (PCR). L&L previously reported that Mohawk, mentioned earlier, partnered with UPM Raflatac to create a labeling material composed of 30 percent hemp and 70 percent PCR.

Printed on Hemp produces a hemp paper that is 50 percent hemp and 50 percent PCR. The company claims the benefits of its hemp paper include ‘45 percent less energy used, 38 percent less greenhouse gasses produced, 45 percent less wastewater generated, 50 percent less solid waste created.’

L&L also previously reported on Acucote’s portfolio diversification into hemp. Targeted to the cannabis industry, Acucote’s 60# hemp paper is made of 25 percent hemp and 75 percent post-consumer wood.

Avery Dennison has also branched out into hemp. The company offers two hemp substrates, one white and one in a natural, green tinged color. Both are 25 percent hemp, 75 percent PCR. Vanita Marzette, senior product manager for wine and spirits, explains the demand for hemp.

‘I'm always on the lookout for more papers that are sustainable. We are getting more and more requests for papers with organic ingredients in it. Hemp was one of the ones we get a lot of requests for, specifically from brand owners and converters who are working with those brand owners who want to bring some of the essence of what is in the bottle to the outside packaging,’ says Marzette.

The company launched the original, natural tone hemp paper in 2019 for the wine and spirits sector and added the white hemp paper in 2020. There are no plans to expand its hemp offering.

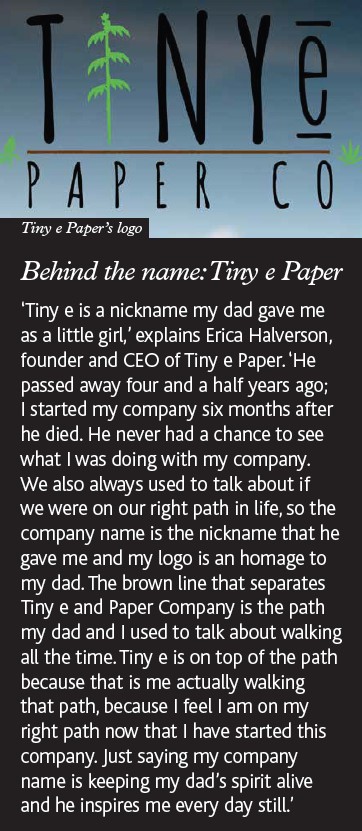

While most companies stay between 25 to 50 percent hemp and rely on tree-based paper, recycled or not, for the remaining percent, one company is a standout in the field of pure hemp paper: Tiny e Paper.

Tiny e Paper

Tiny e Paper, founded in 2017, makes 100 percent hemp paper. According to the company website, Tiny e Paper makes its hemp paper ‘out of hemp stalks and the waste from CBD extractors, taking care of two problems within the cannabis industry.’

To learn more about the company and its products, L&L spoke to Erica Halverson, founder and CEO of Tiny e Paper. Halverson gained an interest in hemp paper after seeing the volume of paper product wasted in packaging in her previous jobs. She founded the company in November 2017 to be a solution to that waste problem. Like Kerr, she is painfully aware of the lack of hemp production.

‘Two thirds of the processing of the hemp stock is exactly the same whether you are making textiles, plastics, biofuel, paper, kitty litter, or horse bedding. You still have to process the plant somewhere. The processing and the supply chain for the hemp stock is not specific for any one industry,’ says Halverson. Because of that, the limited supply has a very large demand for a variety of industries.

‘Two thirds of the processing of the hemp stock is exactly the same whether you are making textiles, plastics, biofuel, paper, kitty litter, or horse bedding. You still have to process the plant somewhere. The processing and the supply chain for the hemp stock is not specific for any one industry,’ says Halverson. Because of that, the limited supply has a very large demand for a variety of industries.

Halverson has a bold mission for her company: ‘My mission is to get everybody to stop using trees for paper and switch over to hemp. If I am truly going to do that, I have to have hemp paper do everything tree paper can do. It has to fold the same, perforate the same, cut the same, glue the same, ship the same, hold up the same – it has to do everything that regular tree paper can do.’

She sees this mission as more timely than ever. ‘Covid has actually increased paper production, increased the need for pulp, and increased the desire for sustainable alternatives,’ says Halverson. 'A lot of people have this idea that with the dawn of the electronic age, paper production and paper use was going to go down the more that we turned to electronics. What Covid showed us is that that is not true. The more that people buy products online, the more we have to ship those products, and we ship those products in paper boxes.’

For Halverson, hemp can be a complete solution. 'The box that you put the product in, the box that you ship it in, the box that you put it on display in the store in, the label that it has around it, the tissue paper inside it, the peanuts in the box, all of that can be 100 percent hemp. There is no reason for paper that is tree paper not to be 100 percent hemp.’

This is one of the key distinctions that separates Tiny e Paper from other hemp paper companies. ‘Most other companies are only 25 percent hemp and 75 percent post-consumer recycled content – that means recycled trees. That doesn't solve the problem,’ says Halverson. Using zero trees is Tiny e Paper’s claim to fame, and is why Halverson doesn’t consider other hemp paper-producing companies to be her competition.

For Halverson, being truly tree-free is of the upmost importance. ‘If we don't figure out alternative resources for all the different products we make out of wood, in 300 years we will be out of trees. When I say that my mission is to save the planet one plant at a time, that might sound like hyperbole but the first plant I'm talking about is trees and it is not hyperbolic to say we have to figure something out.’

While saving trees is a noble goal, hemp is certainly no second fiddle to tree-based materials. ‘There are some natural properties that hemp has on its own that when I make paper out of the hemp stock, those natural properties are in the paper as well. One of those is that its naturally antibacterial, so anything I make out of hemp paper makes that paper antibacterial,’ explains Halverson. ‘Additionally, hemp is UV resistant, so it won’t change color as light hits it and is also naturally water resistant.’

While there are many known benefits of hemp, Halverson admits more research needs to be done. ‘We need repeatable processes and we need the supply chain to exist and product to get into the marketplace in order to get more data and research about end of lifecycle analysis.’

Previous government bans and the limited supply chain availability have crippled this research, but it is vital to quantify hemp’s benefits. ‘We need to be able to quantify and qualify other data points such as how much hemp do I need to use to save 100 trees for example. How can I quantify to customers what it means when you make that switch over? Those are the type of metrics and data points we don’t have yet because this is such a niche industry.’

Even without those studies, Tiny e Paper has pushed ahead with production. Halverson is first targeting the cannabis industry with her packaging options. ‘If you are selling a CBD tincture and I come to you and say “I can make your box from the same plant that you are making your product out of, look at what kind of value proposition that gives you as a brand” that’s a pretty powerful statement. If you are already supporting this plant, then it just makes total sense.’

Learn more about hemp at the Global Hemp Association

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.