Pravesha Industries chooses inspection from Lucid Imaging

With a zero-error production mandate, Pravesha Industries relies on Lucid Imaging’s OptiCheck Label inspection system.

For packaging converters operating in regulated sectors like pharmaceuticals, FMCG and personal care, inspection is not merely a quality checkpoint; it is a compliance mandate. Hyderabad-based Pravesha Industries, a fast-growing packaging converter with a strong portfolio of advanced packaging, operates in this high-stakes environment, where zero-error production is non-negotiable.

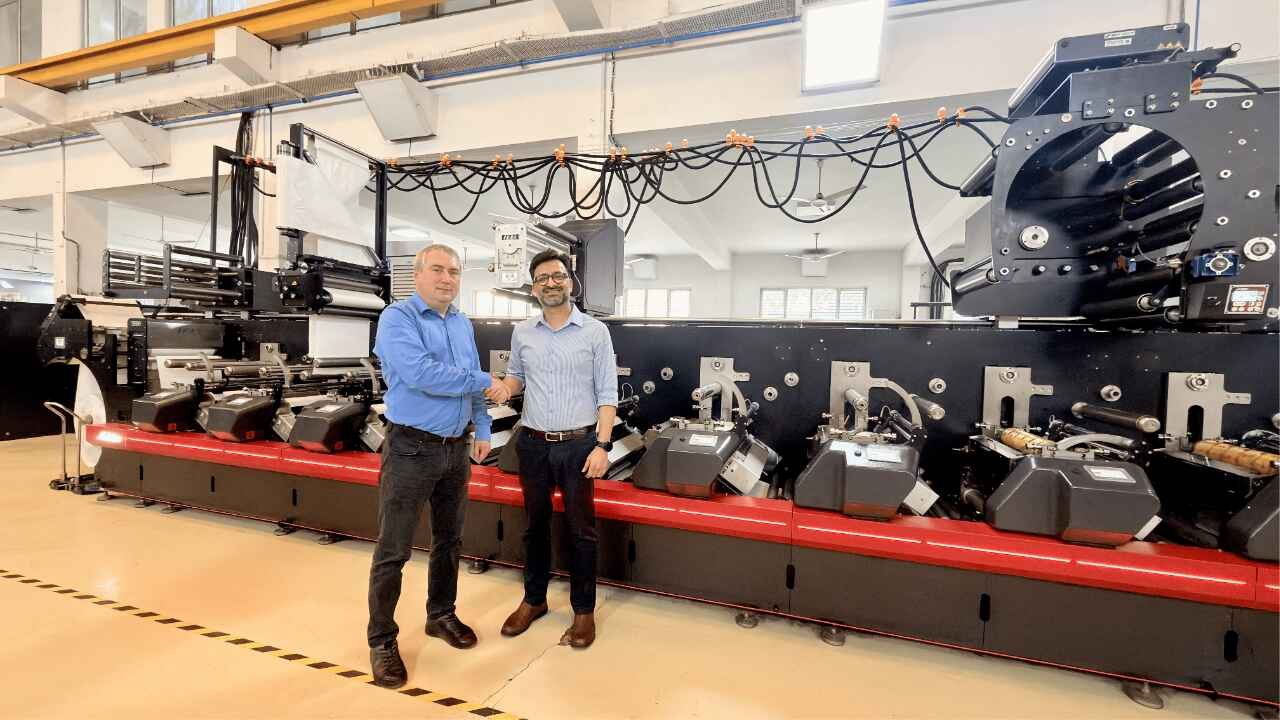

That’s why the company chose Lucid Imaging’s flagship OptiCheck Label inspection system, extending its successful and established partnership.

The stability challenge

The imperative for a new, robust label inspection system arose from significant operational friction experienced with previous technology.

‘We had endured an underwhelming experience with the existing inspection system, which presented critical limitations in defect detection and restricted substrate adaptability,’ shares VC Prasad, plant head-operations, Pravesha Industries. ‘In a modern converting environment handling diverse materials — including paper, polymer, metallic foil and clear-on-clear substrates — limited adaptability directly translates into reduced operational flexibility and increased costs.’

This situation prompted Pravesha to seek a more stable system capable of meeting stringent client expectations. Its search focused on systems that could guarantee compliance with stringent international quality standards demanded by pharma clients, higher stability and detection accuracy and dependable local support.

Lucid Imaging was chosen as the preferred partner not just for its proven past performance with the carton inspection system, but also for strong word-of-mouth recommendations from other converters in the Hyderabad printing hub.

Importantly, Lucid assured minimizing service-level agreement time and maximizing uptime by ensuring fast response times and local availability of spare parts.

‘This local availability effectively offsets potential long-term costs associated with offshore support and delayed spare parts, positioning the domestic solution as the financially superior choice for long-term total cost of ownership,’ notes Prasad.

Technical deep dive

Headquartered in Bengaluru, Lucid Imaging stands out through its deep expertise and advanced technology in high-precision print inspection.

Founded by Anand Chinnaswamy, the company designs and delivers a comprehensive range of inspection systems tailored for the printing industry. Its product portfolio includes high-speed in-line sheet inspection systems for intaglio and offset presses, label inspection systems, web inspection systems, carton inspection systems, VDP (variable data printing) inspection, hologram inspection and PDF proofing technology.

The company holds over 80 percent share in India’s currency note inspection systems, serving as an OEM supplier to India’s security printing presses. This background in security printing, a discipline requiring the detection of microscopic defects and anti-counterfeiting features at extreme speeds, enables Lucid Imaging to equip the OptiCheck Label system with algorithms developed for the most demanding visual tasks.

Sharing the specifications of the inspection system installed at Pravesha, Dheeraj Kumar, product manager at Lucid Imaging, says: ‘The system at Pravesha is equipped with high-end capabilities to meet the demanding requirements of pharmaceutical clients. The core hardware features a 4K trilinear color line-scan camera and a 330mm field of view. This configuration provides impressive inspection resolution, capable of identifying defects as small as 0.01 sqmm. The system can operate up to a maximum web speed of 150m/min.’

The robustness and precision of the system address all Pravesha’s core challenges, ensuring accurate verification of character precision, color deviation, die-cut registration and matrix removal across various substrates using optimized multiple high-bright LED light sources. Kumar continues: ‘Furthermore, the system is upgrade-ready, offering optional modules for variable data verification, PDF matching, varnish and hologram inspection and re-inspection, ensuring the converter’s investment remains relevant as its end-client requirements evolve.’

Strategic partnership

Reinforcing its trust, Pravesha has since placed additional orders with Lucid Imaging. These orders include OptiCheck PDF Proofing for pre-press, new carton inspection units and additional label inspection systems.

‘The reliability instilled by our system and support structure has guaranteed minimal downtime and consistent productivity.

This tangible performance has led Pravesha to elevate its partnership with us from vendor-client to a strategic quality collaborator,’ concludes Kumar.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.