Abbey Labels’ transformative journey with Xeikon

From cautious beginnings to industry-leading innovation, a UK-based converter demonstrates how strategic digital investment drives growth and sustainability.

For a company that spent its first two decades specializing in flexographic printing, Abbey Labels’ transformation into a digital printing powerhouse represents one of the UK label industry’s most compelling evolution stories.

What began as a tentative step into digital technology in 2013 has blossomed into a decade-long partnership with Xeikon, which continues to push the boundaries of productivity, quality and sustainability.

This year marks a significant milestone in that journey, with Abbey Labels becoming the first UK converter to install Xeikon’s new LX3000 digital press, affectionately known as ‘The Lion’, featuring cutting-edge Eco toner technology.

For chairman Tom Allum, the installation represents the culmination of years of strategic investment and forward-thinking.

‘As expected, the Lion has quickly settled into our label operation. This new beast gives us fantastic speed, excellent 1,200 DPI print quality and industry-leading sustainability in one high-productivity package,’ says Allum. ‘As the first full installation in the UK, the Lion is another great opportunity for Abbey Labels to bring more value for our customers.’

The digital leap

Looking back to 2013, Abbey Labels’ entry into digital printing wasn’t made lightly. The company had spent ‘two or three years’ researching digital options before finally committing to the Xeikon 3300 press.

‘Question marks about speed of digital devices, print quality and the space required to set up a digital operation were constantly on our minds,’ Allum recalls of that period. ‘The latest range of equipment from Xeikon did seem to solve our speed queries, and the dramatic improvements in print quality in recent years ticked all of the boxes in that area of concern.’

We have invested in what I truly believe is one of the most, if not the most, environmentally friendly and sustainable digital label printing technology on the market today

What ultimately sealed the deal, according to Allum, was Xeikon’s business model: ‘What really made up our minds in favor of the Xeikon product was the lack of click charge, which simply made costing and quoting for jobs a lot easier, and the fact that the Xeikon people seemed to speak our language.’

That initial digital press was supported by an AB Graphic Digicon 2 converting line, allowing Abbey Labels to offer a wide range of embellishment options. Crucially, the special die-cutting system on the Digicon allowed the company to use its existing stock of over 5,000 cutters from its flexo operation, creating immediate flexibility for new and existing customers.

According to Allum, the results were immediate and impressive: ‘I would say that 90 percent of the job were new, some from existing customers, but most from new clients.’

Local food producers were early beneficiaries, with Abbey Labels’ British Retail Consortium registration for food production and the ISO 14001 environmental certification proving to be a significant advantage in that market.

Expanding digital capabilities

Following that successful initial foray into digital, Abbey Labels didn’t stand still. In 2015, the company added another Xeikon press, demonstrating its commitment to the technology. But the real acceleration came in 2016, when digital sales grew to become a major portion of the company’s turnover.

By late 2022, Abbey Labels was ready for another significant digital upgrade, investing in two high-end Xeikon CX300 presses. Having taken delivery of the UK’s first CX300 in late 2021, the company was so impressed with the productivity and consistency of quality that it installed a second machine less than 12 months later as part of an ambitious 1 million GBP (1.3 million USD) investment plan.

‘As the most productive press at the 330mm width at the time, not only did the Xeikon CX300 retain the highest print quality on a broad range of challenging substrates and delivered in terms of speed, but it also minimized the environmental impact of label manufacturing by not emitting any harmful substances (VOCs) or generating water pollution and by using only a minimal amount of electricity,’ Allum explains.

The speed advantages were substantial. The advanced Xeikon CX300 ran at 30m/min, with each full-color machine offering a production capacity of over 50,000sqm per month in a single shift. Thanks to the LED imaging head, which operates at 1,200 x 3,600 DPI, the print quality is equivalent to that of gravure and offset.

‘The speed and automation on the CX300 delivered 25 percent more efficiency compared to our existing Xeikon CX3s, allowing us to operate the business in a very agile and responsive manner,’ notes Allum. ‘We added 50 percent more capacity in less than a year, whilst retaining a similar footprint and the same operators, so the implementation was very smooth.’

The Lion roars

Abbey Labels’ most recent Xeikon investment represents its most ambitious digital move yet. In January 2025, the company became the first in the UK to install the new Xeikon LX3000 at its Suffolk facility.

This high-speed press prints at speeds of up to 42m/min, significantly improving over previous models, and features Cruise Control inspection to ensure the highest quality labels. But perhaps most significantly, the LX3000 takes advantage of Xeikon’s new Eco toner technology, which reportedly reduces the carbon footprint of the process by more than 10 percent.

‘Not only does the impressive 40 percent speed increase provide more printing capacity, it also reduces the energy consumption per linear meter,’ notes Allum, highlighting the dual benefits of the new technology.

The Eco toners represent a major leap forward in sustainability. Made with 60 percent recycled plastic materials, free from PFAS and certified vegan, they maintain the food-safe characteristics of Xeikon’s older toners while significantly reducing environmental impact.

‘Our brand owner clients demand proven sustainability to help reduce their carbon footprints, so we’re particularly pleased to be able to offer all the green benefits of Xeikon’s new Eco toners. This was a definite selling point for us,’ Allum explains.

The deal was sealed in at drupa in June 2024, fulfilling a long-held ambition for Allum.

‘Ever since I first started visiting drupa as a teenager with my dad, I’ve dreamt of signing for a new press at the world’s largest print show,’ he recalls. ‘We’d only just agreed to invest in the LX3000 the day before the show closed, so we had to make quick arrangements for the trip to Düsseldorf. It was well worth it, though, because it’s so much better to finalize these deals in person.’

A balanced approach

While Abbey Labels’ digital journey with Xeikon has been remarkable, the company hasn’t abandoned its flexographic roots. Indeed, a key part of its success has been knowing when to use each technology for maximum effect.

Since 2016, the company has made significant investments in state-of-the-art flexographic printing machines alongside its digital expansion.

‘The combination of flexographic and digital machinery offers our clients an unrivaled all-around package to produce their label orders in the best and most efficient ways possible,’ notes the company’s history section.

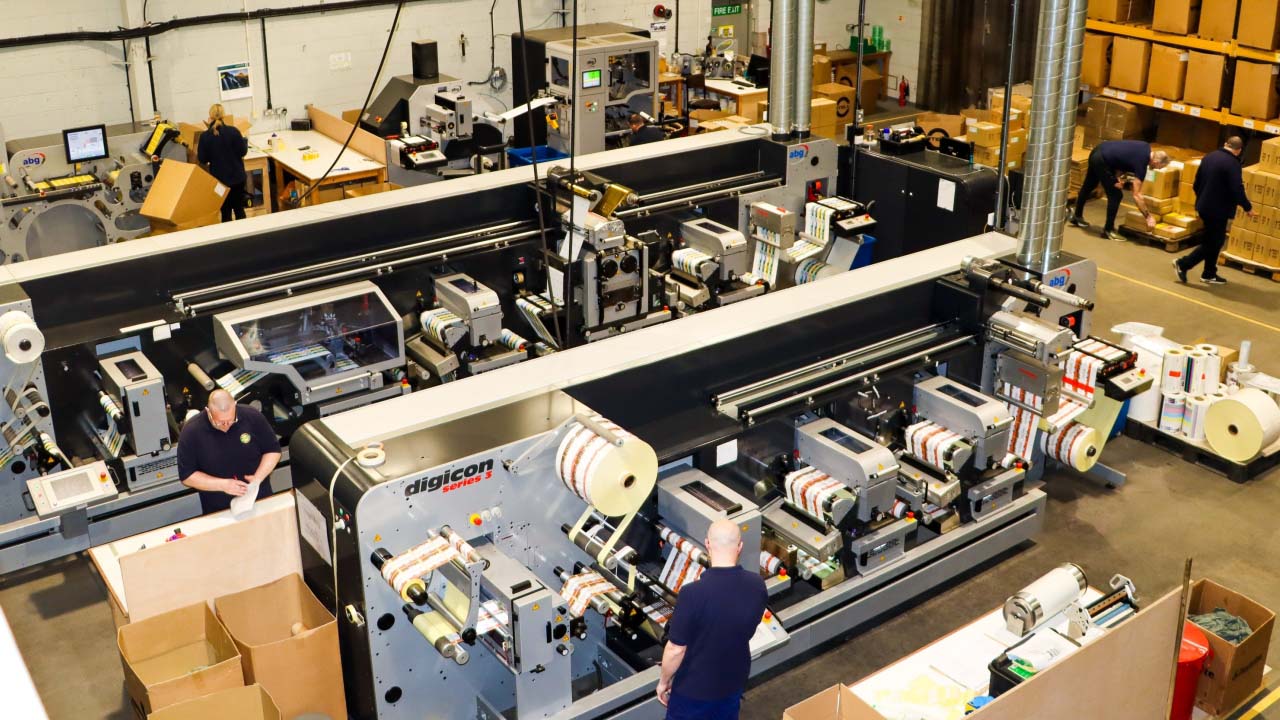

This balanced approach also extends to the company’s finishing capabilities. In May 2023, Abbey Labels installed three new finishing machines from AB Graphic International, including a Digicon Series 3 line dedicated to peel-and-reveal and multilayer labels, an automatic Vectra turret rewinder for faster changeovers, and a flatbed screen-printing unit for added-value embellishments.

‘We already have rotary screen-printing in our flexo department, but it is better suited to longer runs,’ says Allum. ‘We needed to add flatbed screen capabilities to make further headway into the beverages, vape and supplements markets, plus existing customers in other industries have been requesting it for a while.’

Digital benefits

For Abbey Labels, the advantages of its Xeikon digital presses have been numerous. The high-definition output ensures sharp images and perfect registration regardless of run size or material type. The technology has allowed the company to serve markets previously out of reach due to volume or cost constraints, particularly in the food sector, where its BRC certification gives it an additional edge.

The environmental benefits have become increasingly important as well.

‘We have invested in what I truly believe is one of the most, if not the most, environmentally friendly and sustainable digital label printing technology on the market today,’ says Allum regarding the latest Xeikon installation.

As expected, the Lion has quickly settled into our label operation. This new beast gives us fantastic speed, excellent 1,200 DPI print quality and industry-leading sustainability in one high-productivity package

Danny Martens, marketing manager at Xeikon, notes the strength of the partnership: ‘Abbey Labels has built up a very strong digital label printing business based on Xeikon dry toner technology, going right back to 2013 when the first Xeikon 3300 press was installed, and we are proud to continue this great partnership.’

Ser van der Graaf, sales area manager of labels, graphic arts and carton packaging for Benelux, United Kingdom and Ireland at Xeikon, adds: ‘Abbey Labels is a progressive, growing business, and Xeikon is proud to be their partner. It’s great to be supporting the company in their investment decisions and play a part in their future success.’

The road ahead

With the new Xeikon LX3000 now fully operational, Abbey Labels is positioned for continued growth.

‘Just a few weeks in, we’ve seen a big change in our turnaround times and output speeds, as the Lion is literally eating label job after label job in no time at all,’ Allum reports. ‘With this press and the new Eco toners, we’re ready for the next chapter in our history.’

That next chapter promises to build on the foundation of innovation, sustainability and customer-focused products that have defined Abbey Labels’ journey from a general printing business in the 1980s to one of the UK’s top label converters.

Having accelerated digital printing capacity by 50 percent over the past couple of years and made significant investments in new converting capabilities, Abbey Labels appears well-positioned to maintain its upward trajectory in an increasingly competitive marketplace.

For Allum and his team, the transformation from flexo specialist to digital innovator might be complete. Still, the evolution continues with Xeikon technology likely to remain at the heart of the operation for years to come.

‘This is not the end,’ as the company’s history section concludes, ‘just the beginning of the next chapter in the Abbey Labels Story.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.