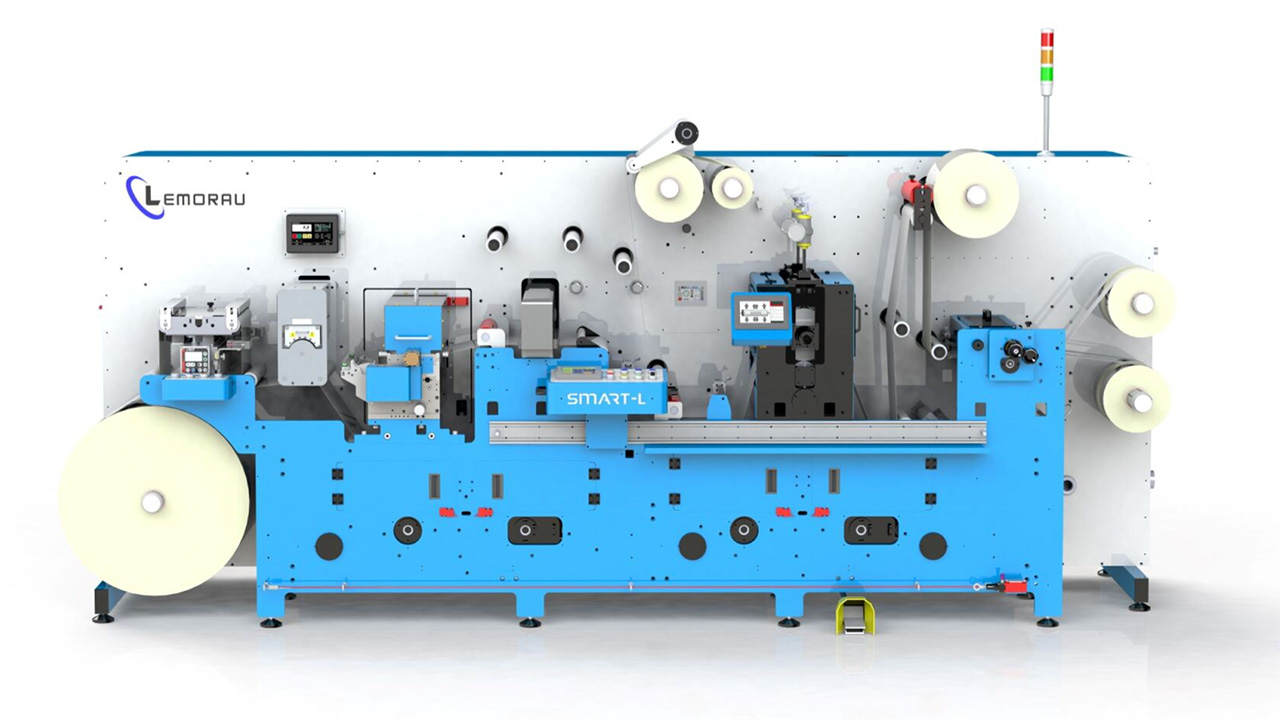

AstroNova launches two compact digital label presses

New inkjet systems target label converters and print service providers

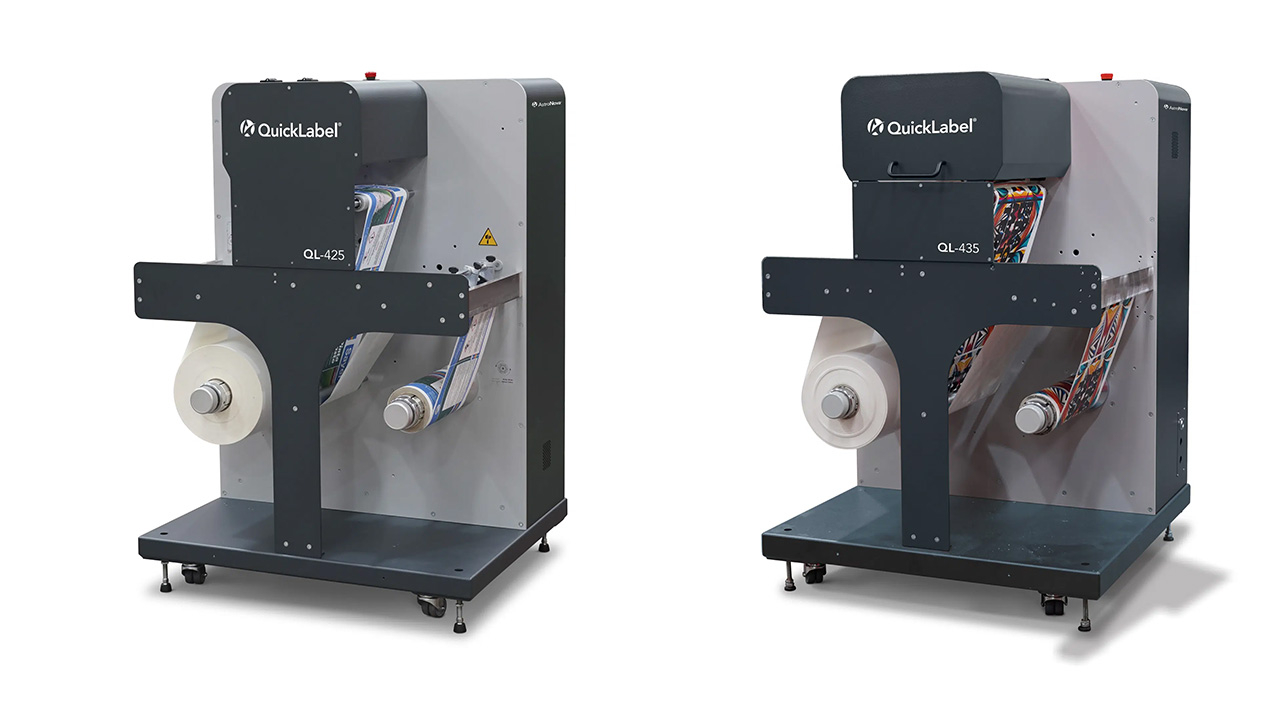

AstroNova Product Identification has launched two high-performance compact digital inkjet label presses, the QuickLabel QL-425 and QuickLabel QL-435, expanding the company's portfolio of professional printing systems designed to meet the growing needs of label converters, print service providers and high-volume brand owners.

The QL-425 (A4 width) and QL-435 (A3 width) feature high-quality printing, operational simplicity, and a low total cost of ownership. Both models are engineered for flexibility and ease of use, making them suitable for medium to high-volume label and flexible packaging production.

'This is not just a refresh. These latest additions to our professional label printing segment represent a complete rethink of what professional onsite medium to high volume production can look like,' said Greg Woods, CEO of AstroNova. 'We've designed these machines to give converters and PSPs the edge they need: more control, more uptime and significantly lower operating costs. Because of the flexibility of our new print engine system, there is greater commonality of components across our products, enabling further flexibility for support and future upgrades that address inventory requirements for the users and ourselves.'

'With the QL-425 and QL-435, we're introducing powerful, cost-effective label press options for customers who need compact, capable and intelligent printing,' added Mike Natalizia, CTO of AstroNova. 'These systems are designed to help users expand capabilities, reduce operating costs and stay competitive.'

The label presses deliver optimized ink usage, energy-efficient operation, and reduced maintenance cycles. Operators can choose between dye or pigment ink configurations, enabling a single platform to support both vibrant, full-color labels and durable, abrasion-resistant prints across a wide range of materials.

The QL-425 and QL-435 are designed for compact, floor-top placement and fit easily into tight production spaces, providing full access to all components for streamlined operation and fast maintenance.

Both models are equipped with AstroNova's proprietary real-time diagnostics and monitoring software, which supports predictive maintenance, remote service, and over-the-air updates for maximum uptime. The integrated InEdit RIP software delivers an end-to-end digital workflow from file preparation to print management.

Both new label presses feature AstroNova's machine intelligence platform, providing users with visibility into press health, performance metrics and consumable usage. The result is reduced operator workload, fewer service calls and a simplified, data-driven approach to print management.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.