Label Express expands operations with Cartes Gemini

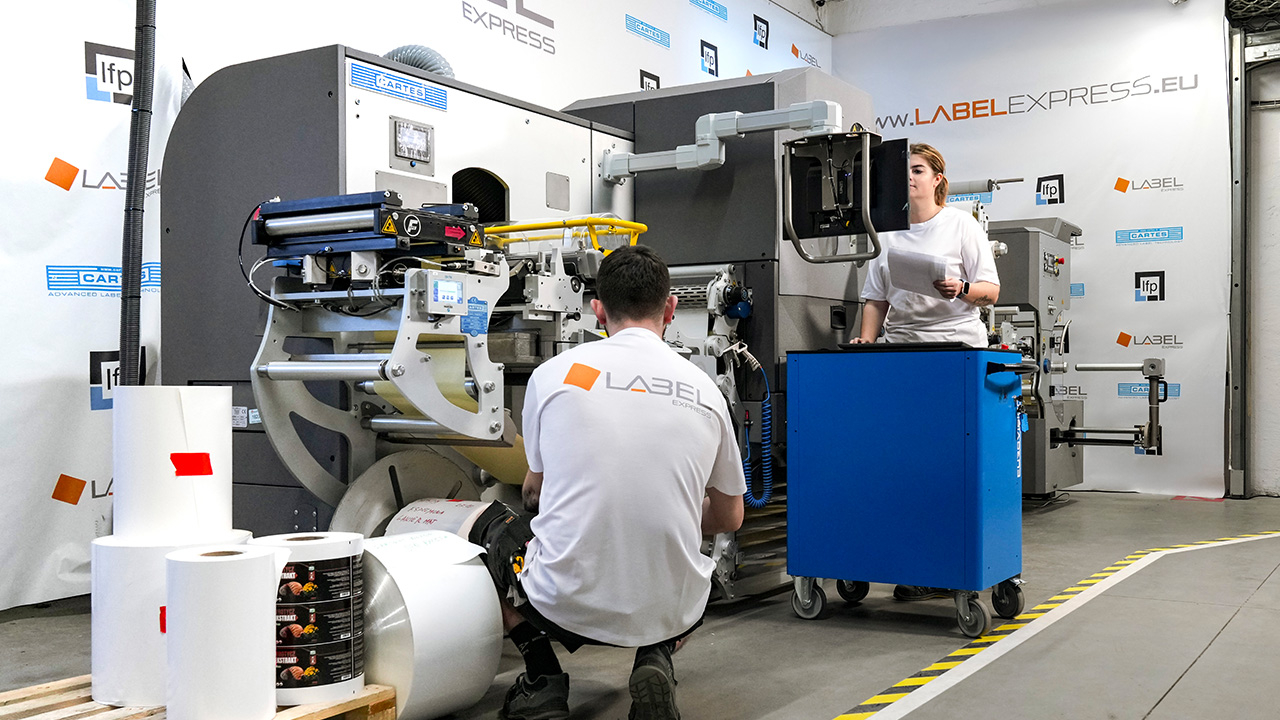

Polish label printer increases its production quality and efficiency with Gemini GE362WL.

Polish online label printing specialist Label Express, a division of Labo Printing, has invested in a Cartes Gemini GE362WL to increase its production quality and efficiency.

Launched in 2013 with just five employees, Labo Print now has 450 staff and is one of the leading players in digital printing services in Europe. The company’s management established the LabelExpress division, invested in Durst Tau narrow-web inkjet printers, and adopted laser die-cutting technology.

‘Our standard production time is three working days, but we can fulfill orders in a single day and deliver them precisely when our customers need them,’ said Sławomir Góral, managing director of Label Express. ‘This is made possible by a fully digital workflow, allowing us to quickly produce from the customer’s file while eliminating the costs and delays of physical dies.’

Labo Print’s initial preference for UV inkjet printing and laser die-cutting was driven by the extreme variety of materials, shapes, graphic designs, sizes and quantities. However, the first years of field experience revealed both the strengths and limitations of these technologies. In laser cutting specifically, the company encountered issues with cut quality and automation and began exploring new options. Among them, Cartes’ platform stood out as a suitable option.

‘Gemini is unique for its range of accessories, modularity, and automation level, and it offers technological features that no one else can provide today,’ added Góral. ‘Moreover, Cartes is a company that invests early in future technologies, and we’re confident they will support us in our growth.’

With guidance from LFP Industrial consultants, local distributors of Cartes equipment, the company selected a dual-laser head configuration, including the patented ILC (Invisible Laser Cutting) technology, designed to optimize label cutting on dark-colored prints by avoiding visible white edges. It also adopted the IML conveying system, which enables easy production of individual stickers. Thanks to a six-blade cutting group with automatic positioning and the ACO (Automatic Change Over) technology with barcode reader, Gemini performs job changes autonomously, processing different jobs on a single roll without halting production. At the end of the line, the ATR-360 turret rewinder with automatic extraction facilitates job separation.

‘In developing the latest generations of converting platforms, laser die-cutters, and Jet D-Screen digital embellishment modules, our R&D department considered even the most extreme use cases,’ commented Natalia Tšamorina, export sales manager at Cartes. ‘The new dynamics driven by online printing, as well as the specific needs of companies like Labo Print, have presented increasingly complex challenges. These have pushed us to develop platforms like Gemini, which is generating strong interest from both large and small online print providers.’

In addition to the hardware, the combined expertise of Cartes and its partner LFP Industrial in software and integration played a key role in Label Express’s success, enabling the quick connection of Gemini to the company's workflow management systems.

‘We already handle over 100,000 orders per year and want to continue growing. The label segment will become increasingly important to us,’ said Krzysztof Fryc, CEO of Labo Print. ‘Cartes offers a one-of-a-kind technology, and LFP Industrial Solutions has been a trusted partner throughout the collaboration—from equipment installation to software consulting.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.