Esko launches XPS Spark 4835 plate exposure unit at Labelexpo

The unit combines single-side UV LED exposure with an optional integrated UV finishing device in one compact package.

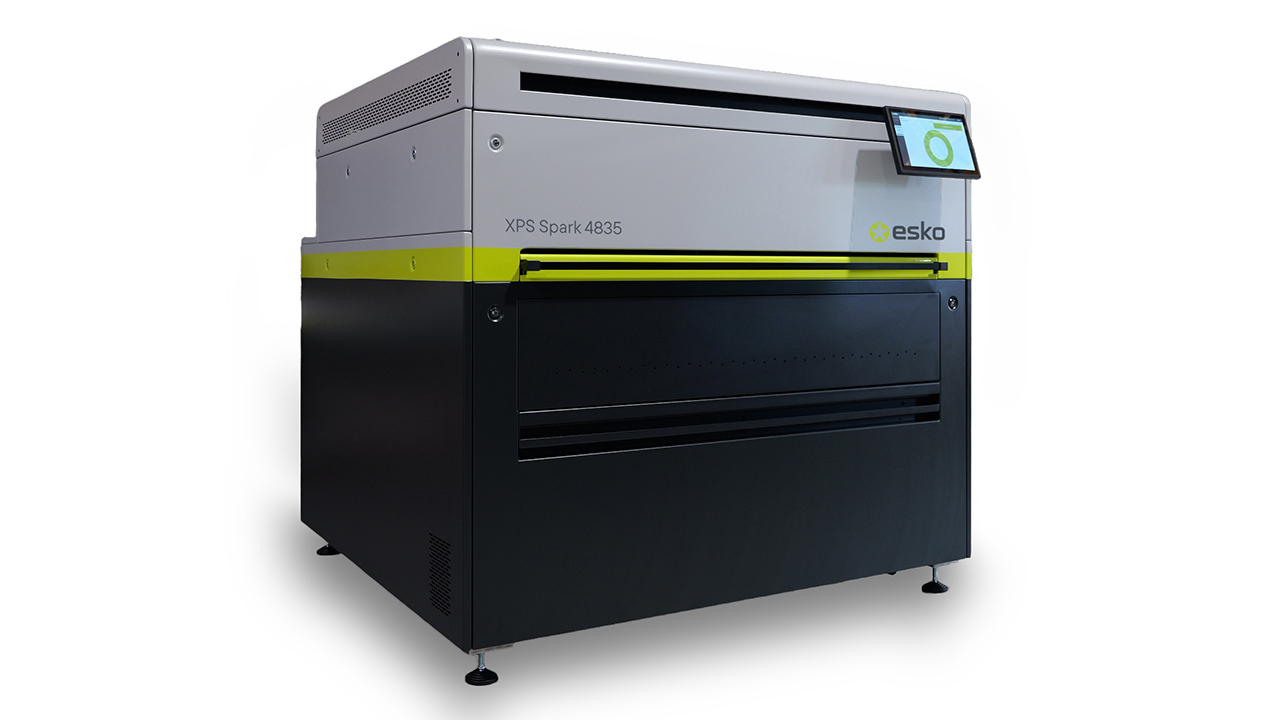

At Labelexpo Europe 2025, Esko unveiled the Esko XPS Spark 4835, a new plate exposure unit that delivers high performance with a small footprint.

Designed for packaging converters and trade shops seeking precision, sustainability and simplicity, the new XPS Spark combines single-side UV LED exposure with an optional integrated UV finishing device (UVA + UVC) in one compact and optimized package.

Unveiling the newest member of the Esko flexo ecosystem on day one of Labelexpo, Eddy Fadel, Esko GM flexo, explained that the development of the new XPS Spark underlined the commitment to sustainability shared by Esko and the wider Veralto family of companies. 'We are developing solutions and innovations that help our customers achieve their own sustainability objectives through reducing energy consumption and replacing bank exposures in the market,' said Fadel. 'The new XPS Spark meets a clear need in the label market for a single-sided, all-in-one LED plate exposure system that is both at the forefront of innovation and quality while benefiting from a competitive price.

'Thanks to the hard work and experience of our teams, we have achieved this in record development time with the new XPS Spark,' added Fadel. 'Following this unveiling at Labelexpo, external testing will begin later this year before we release worldwide in the second half of 2026.'

Speaking at Labelexpo to the large crowd gathered at the Esko booth in the Fira Gran Via convention center, Barcelona, Pascal Thomas, Esko director of flexo product management, said: 'With its compact footprint, intuitive operation and flexible exposure control, the XPS Spark is designed to make high-quality LED plate exposure accessible to a broader range of flexo users.

'The XPS Spark offers an intuitive, hands-on workflow, providing an open parameter system that gives users complete control. Whether a business is looking to upgrade from analog tubes or expand its platemaking capabilities, the XPS Spark delivers the performance, precision and adaptability needed to meet today’s sustainability demands in flexo plate production, without the complexity,' he said.

The XPS Spark 4835 delivers consistent quality, outperforming analog bank exposure systems with XPS plate quality. 'As well as delivering optimum quality, the XPS Spark speeds up work with a full LED exposure surface,' added Thomas. 'This also improves energy efficiency and lowers operating costs while contributing to sustainability objectives by eliminating tube waste.

'With floorspace at a premium, we know the high cost of owning or renting space is a serious problem for many converters and trade shops,' he said. 'The XPS Spark is ideal for operators with space-constrained environments, so there is no longer any need for those businesses to compromise on plate production and quality due to a lack of available space.'

The new Esko XPS Spark's features include homogeneous exposure, with patented kaleidoscopic optics that ensure that UVA light is evenly distributed across the entire plate surface, eliminating hotspots and shadows that are common with traditional bank exposure systems.

The XPS Spark utilizes single-side UVA LED exposure, supporting both round-top and flat-top dot plates. The achieved dot shape is plate-type dependent.

The optional integrated UV finishing drawer can be added to the XPS Spark to complete the plate exposure process in a single device. It uses UVA/C light to finalize the plate after LED exposure, eliminating the need for a separate finishing unit.

The XPS Spark uses an air-cooled UVA LED exposure system, which eliminates the need for complex water-based cooling. This design simplifies installation and maintenance while keeping the system compact and cost-effective.

It also features a fully open exposure parameter system. While the XPS Spark doesn’t include predefined plate parameters, it supports all flexo plate vendors, who can provide optimized settings. Users can further fine-tune and adapt settings to meet specific production needs, ensuring flexibility and precision across any workflow.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.