MicroDynamics launches intelligence platform for anilox data

Cloud-based intelligence platform that facilitates access, analytics and decision making.

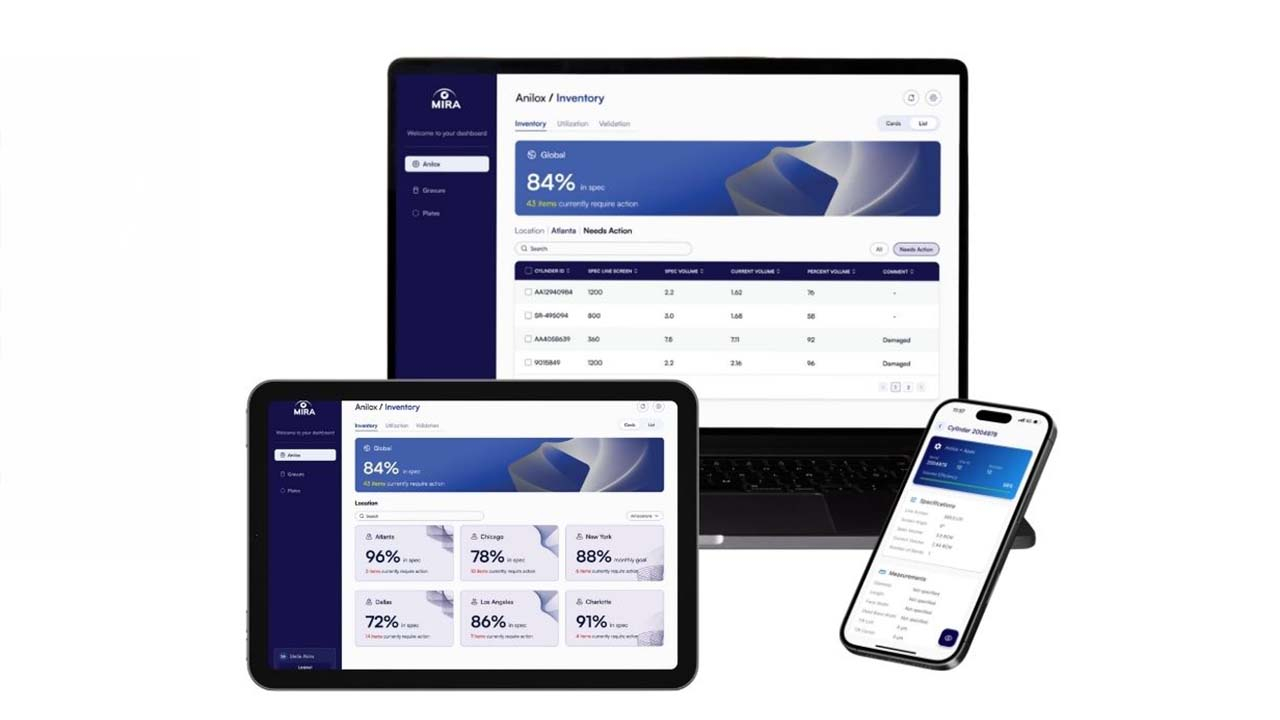

MicroDynamics has launched MIRA, a cloud-based intelligence platform that facilitates access, analytics and decision making on anilox data for Veritas users across multiple locations worldwide.

‘Anilox inspection is entering a new era,’ said Brent Zurcher, director of operations at MicroDynamics. ‘With MIRA, printers, suppliers, and partners will finally have the visibility and collaboration tools they need to make smarter, faster, data-driven decisions across multiple sites and inventories.’

MIRA is a secure intelligence platform that enhances anilox quality control by making data accessible, actionable and shareable, anytime and anywhere through web and mobile.

The platform delivers visibility of anilox inventory across sites. Multiple departments, from QC to management, can share data, track roll history and performance, monitor instrument utilization, set up alerts and thresholds and optimize cleaning, maintenance and inventory like never before.

MIRA connects printers and suppliers on one intelligent platform, enabling clear communication and shared analysis of anilox data that drives accountability, collaboration and stronger partnerships. With automated alerts, streamlined communications, and the proven accuracy of Veritas, suppliers can support customers, resolve issues faster, and manage relationships.

MIRA’S intelligence system will power a new wave of automated products and technology services. This includes MIRA Robotics, an automated MIRA integration that delivers 100% machine-controlled Veritas operation.

MIRA Robotics enables fully autonomous operation of Veritas inspection systems through API integration, unlocking in-process measurement capabilities. By integrating directly into presses, cleaners and a wide variety of equipment, MIRA Robotics brings the power of Veritas measurement while eliminating the need for human control.

MIRA Robotics is already proving its value inside BW Converting’s PCMC Meridian Elite+ laser anilox cleaner and TWEN’s TAC_M_Micro laser anilox cleaner. With Veritas integrated directly into these solutions, users can clean, inspect and analyze anilox quality in one system, at the push of a button.

Carl L Powell, chairman of MicroDynamics, commented: ‘MIRA is an Industry 4.0 solution built for the next generation of the print workforce. For the first time, printers can see anilox data across multiple sites in one connected, user-friendly view, automate what once required hands-on oversight, and put their data to work, manually or automatically. This is not just measurements—it’s optimized intelligence for the future of the industry. I’m extremely excited for the power MIRA will bring to our customers and partners.’

MicroDynamics will present MIRA and MIRA Robotics at Labelexpo Americas (Apex Booth #5G40) and the FTA Fall Technical Conference this September.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.