AirTrim launches cutter sharpening program

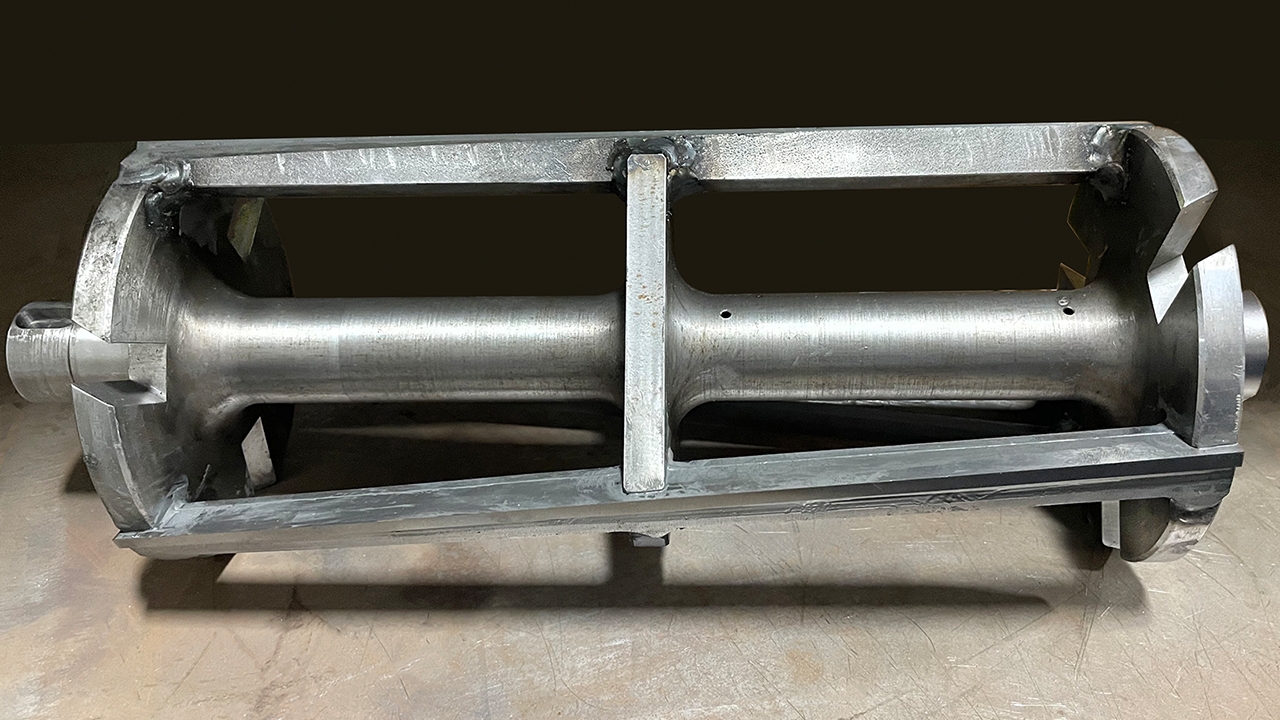

AirTrim, one of the leaders in designing and manufacturing trim waste and dust containment systems, has introduced the AirTrim Cutter Sharpening Program (ACSP), which returns Lundberg cutters to like new condition.

According to the company, sharpening worn cutter blades increases efficiency and productivity while minimizing cutting costs and downtime. Worn cutter blades may miss cuts, leading to longer trim, higher bearing load and ultimately shutdown of the cutter, stopping production altogether.

ACSP process is straightforward, economical and ideal for paper film and foil converting, printing, label making, direct mailing and fulfillment operations, or wherever trim waste cutters are used.

Upon receiving cutters (without motors) and 2-3 feet of material, AirTrim engineers will examine the cutter and advise if additional work is beneficial. They then sharpen the rotor and fixed blades to create a new cutting edge, reassemble the cutter with new bearings, and reset the cutter blade to cut the supplied material.

The old bearings, the cut bag sample and the reconditioned cutting unit are returned.

AirTrim can also enroll interested parties in its reminder service for future cutter maintenance and provide a rugged, compact wooden shipping container for future trim cutter sharpening if desired.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.