Tresu adds service program to maximize workflows that feature its ancillary equipment, printing units and processes

Tresu Group has introduced Global Service Concept, a new holistic care program that it said enables customers worldwide to gain maximum value from complete workflows that feature its ancillary equipment, printing units and processes.

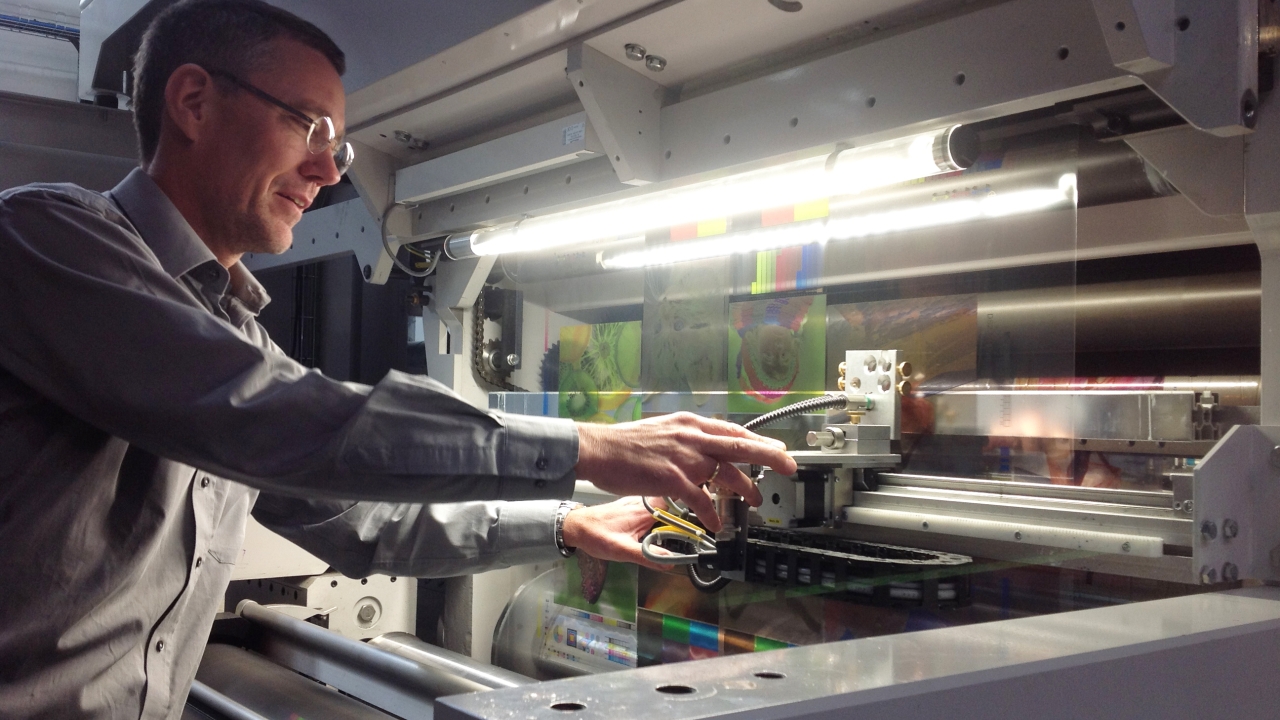

Under the supervision of experienced Tresu technical staff, Global Service Concept comprises round-the-clock support, on-going machine optimization, training and testing. On-site services include management of installations, maintenance and repairs, and consultation to help customers implement lean and cleaner manufacturing practices in areas such as set-up time reduction, ink and substrate performance, and human-machine interaction. Furthermore, Tresu’s test and demonstration center at its global headquarters will be used as a location for training programs that give operators and staff in-depth understanding of the equipment and hands-on experience with machine components.

Peder Larsen, Tresu Group global service manager, said: ‘In an age when service flexibility is the key to providing competitive edge, printers depend on solutions that deliver lowest total ownership cost, repeatable quality and optimisation of productivity. And with end-users demanding tighter colour tolerances and shorter production runs, problem-solving and maintenance can only be effective when taking the whole process into consideration.

‘Global Service Concept, backed by a team of skilled technicians with up to 20 years of industry experience, gives printers the reassurance of smoothly integrated systems that work to full potential throughout the product life, full control the process, and waste minimisation at every stage.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.