Erwin Müller improves e-commerce shipping with Bixolon

The textile retailer installs Bixolon’s XL5-40CT direct thermal linerless printer with LCD display and serial and Ethernet interfaces

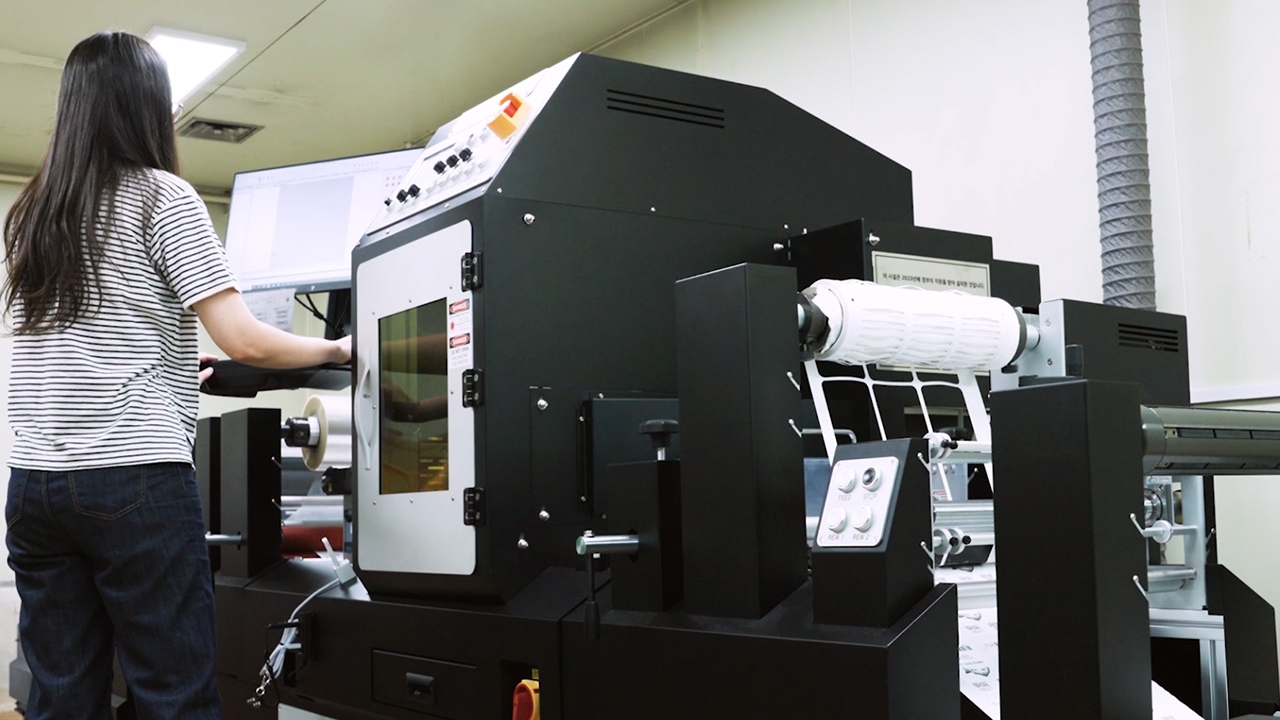

Mail order and e-commerce retailer Erwin Müller Versandhaus has acquired and installed Bixolon’s XL5-40CT direct thermal linerless printer with LCD display and serial and Ethernet interfaces in conjunction with GreenForest IT and Bixolon.

Erwin Müller was founded in Germany in 1951. The family-run textile wholesaler has expanded over the years to become one of the leading mail order companies for home and household textiles. It has been trading online in the DACH region since 1997, and it scaled its operations internationally in 2009.

Erwin Müller sought a labelling printer that would enable it to reduce waste during printing (for example remove the need for liners); enable it to deal with challenges associated with media storage on printers; and to reduce the expensive purchasing costs related to the previous traditional liner label printer that it used for goods receipts, transfers, production orders and item refinement. Erwin Müller chose a linerless labelling printer that could be seamlessly integrated with its existing shipping and order fulfilment system.

Andreas Straub, head of IT, Erwin Müller Versandhaus said: ‘During the selection process, we had to consider factors such as compatibility of new technology and their existing systems, the availability of the required hardware and software and the overall feasibility of implementing the solution within our shipping department.’

Erwin Müller worked with system integrators Greenforest IT and Bixolon to put together a tailored linerless printer for the retailer. Erwin Müller purchased the Bixolon XL5-40CT Direct Thermal Linerless printer with LCD display, with serial interface and Ethernet connection, capable printing at 203 DPI print resolution. The printer is connected via an IP and configured to print from PCs running on a Windows system based in the warehouse.

Erwin Müller has successfully deployed the new printer within its shipping department. The new printers drive efficiency gains and have reduced costs, contributing to the overall improvement of shipping. They also reduce waste and align with the company’s efforts to reduce the environmental impact of its labelling process during fulfilment.

Andreas Straub, head of IT, Erwin Müller Versandhaus added: ‘The implementation of the Bixolon linerless printing solution has improved our shipping operations by increasing efficiency and speed, reducing waste and cutting down on operational costs. It contributes to a more environmentally friendly and cost-effective approach, positively impacting the company’s overall performance.’

Jay Kim, managing director, Bixolon Europe said: ‘Erwin Müller is a leader in its field and it has been great for Bixolon to help it improve the operational efficiency within its fulfilment centers during shipping through using our XL5-40CT Direct Thermal Linerless Printer. Labels and the printing thereof are so important as part of the shipping process for e-commerce retailers, and this applies to almost any warehouse and logistics environment.’

Kim added that Bixolon’s technological advancements and innovations are a key reason behind the selection of its printers by customers. Highlighted in products such as the XL5-40, Bixolon holds the mechanical expertise to navigate the ongoing print and maintenace complexities which are required when working with linerless adhesive media.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.