Bridging the technology divide

David Lanska links the past to the future of package printing in Milwaukee for the latest FTA Great Lakes technical meeting

As machinery moaned in the background, attendees at the FTA Great Lakes Fall technical meeting were presented with a juxtaposition of eras and technologies fighting for a place in the package printing market of tomorrow. Surrounded by examples of time-tested, solidly engineered equipment including a still functional Kempsmith milling machine built in 1888, the meeting focused on the challenge of integrating the newest production technologies into the package printing workflow in order to achieve exceptional store-shelf impact and customer engagement.

Kempsmith has adapted its business by moving into carton die production, and Brett Burris, Kempsmith’s president, showcased a variety of examples garnered from the grocery store shelves to demonstrate how cartons today are engineered to entice consumers to buy the products. He said, ‘the carton is the billboard and the printer is the artist.’ Through the addition of graphics, embossing, promotions, unusual shapes or added functionalities, the cartons grab attention and engage consumers at the point of purchase.

As packaging design features evolve to higher levels of quality and intricacy, the processes for producing them has made stellar leaps to meet the need. Flexible magnetic dies have replaced the extremely expensive die tooling of the past. Where a conventional die could cost upwards of $20,000, a magnetic die can be produced for about 1/10 the cost. Magnetic dies add precision, reducing costs, increase die life, and reduce machine downtime for replacement. Rotary die-cutting equipment with mating cutters penetrate the stock from above and below, producing a cleaner cut at higher operating speed than the traditional ‘crush-cut’ methodology. All of this results in faster, higher-yield production of value-added packaging.

Wisconsin leads digital innovation?

An intriguing note to the presentation given by Victor Gomez, Durst VP of sales North and South America, was the historical tidbit that placed Wisconsin at the forefront of the digital revolution as well as the industrial revolution. He pointed out that the Wisconsin Integrally Synchronized Computer (WISC) was an early digital computer designed and built at the University of Wisconsin–Madison.

Digital computing technology has obviously come a long way since then, having a dramatic impact on every process it was incorporated into. In 1936, across the world from Wisconsin in a small town in the Alps, the Durst brothers formed a company to produce photo imaging equipment. The addition of digital computing into the imaging process resulted in flatbed inkjet imaging technology that overnight rendered previous versions obsolete.

Just as Kempsmith looked to new technologies and markets to continue its growth, Durst developed a wide variety of printing and imaging technologies to serve growing specialty markets. They produced narrow and wide format systems for printing onto ceramic tiles prior to curing and devised custom ink sets to provide visibility and durability for printing traffic signs. To improve sustainability, they produced equipment that printed the surface of various flooring materials to simulate exotic and endangered wood.

Increased precision, reduced costs, enhanced features, increased productivity, greater versatility and faster speed to market were the goals driving the evolution of digital print technology. Durst’s entry into digital label printing technology was predicated on predictable, consistent and repeatable results produced from a color management methodology that replaces the artisan mentality with a scientific approach to color. Gomez describes this as ‘the promise of digital’.

With a host of new features and improvements coming out at a blistering pace, digital printing is rapidly advancing in its ability to deliver the graphic and performance attributes that engage consumers and drive sales. Digital inkjet presses are capable of running eight colors for an expanded color gamut with liquid varnish. Constantly circulating ink through filters removes impurities that can plug inkjet nozzles, vastly improving operating performance. Isolated tensioning from stage to stage provides label to label registration accuracy far superior to web averaging. The digital workflow accommodates variable data such as sequential numbering and personalization, and allows for rapid job change with minimal waste. Through modular construction, label production can incorporate a variety of finishing processes in-line including hot foil, lamination, die-cutting, priming/pre-coating, matrix removal, slitting and more.

With all of this capability, where does digital go from here? Victor sees greater adoption of UV curable ink-jet technology as a means to reduce VOC’s, allow for greater versatility in substrate selection and enhance graphic and end-use properties of the labels. LED lights after each station ‘pins’ or stabilizes the ink to prevent spreading. UV lamps at the end complete the curing process.

With technologies changing at such a fever pitch, how do printers/converters plan for their immediate and future business needs? Label and Labeling Magazine conducted its annual North American Label Converter survey to determine the state of the industry and what forces are shaping its direction. In her presentation, Danielle Jerschefske, North America editor for L&L, said that she sees printers facing rising costs for everything from equipment, consumables and insurance to labor and energy. At the same time, they are being squeezed by downward price pressure for their products. While printers see commoditization of label pricing, label buyers continue seeking more value-added features.

In order to increase efficiencies, reduce waste and incorporate the boutique design elements print buyers seek, 57 percent of respondents indicated that they are looking to invest in capital equipment in the next 12 months. That number balloons to nearly 75 percent anticipating a capital purchase over the next 24 months. With so many converters seeking a competitive advantage through capital equipment, the key for success is in realistically evaluating press decisions against existing and projected needs.

Some of the intriguing trends coming from the survey:

- packaging reduction

- down-gauging

- reduced run lengths

- shorter product lifecycles

- environmental challenges / sustainability

- the rise of the private label

- more product variations

- end users becoming pure marketing and sales operations

- reduced time-to-market

- more mergers and acquisitions

According to Jerschefske, much will go digital. The survey indicated that printers recognize the value of digital for shorter run lengths and variable data. As a result, 15 percent of all roll label presses installed worldwide in 2009/2010 were digital. Among the 35,000-40,000 label printers worldwide, 1600 digital presses have been installed to date with 300 additional expected before the end of the year. This makes a strong case for digital as a continuing growth market moving forward. Does that mean you should run out and purchase a digital press? Not necessarily, especially when you consider that only three percent of label converters use digital. With technology changing so rapidly, it tends to obsolete just as rapidly, which is why it is so important to carefully evaluate press decisions against existing and projected needs.

Sustainability continues its march into the world of print. Over 85 percent of respondents saw sustainability as important to their business, considering sustainability to be a means to reduce waste and waste-related costs, as well as to address growing customer demand for sustainability through the supply chain. They see lean manufacturing as complimentary to ‘green’ manufacturing.

Probably one of the most important trends is that of actively seeking to engage the consumer at the point of purchase. iPhone technology combines seamlessly with social media (Facebook fan pages, Twitter, Youtube and even Linkedin) to generate buzz, gather feedback, educate consumers, and initiate dedicated marketing promotions. The application of UR codes for prize promotions and snap tags for information gathering (survey questions), fanfolded recipe inserts for consumer education, and thermo chromatic ink on a beer can are just a few examples of interactive packaging geared to attract the 21-35 age group.

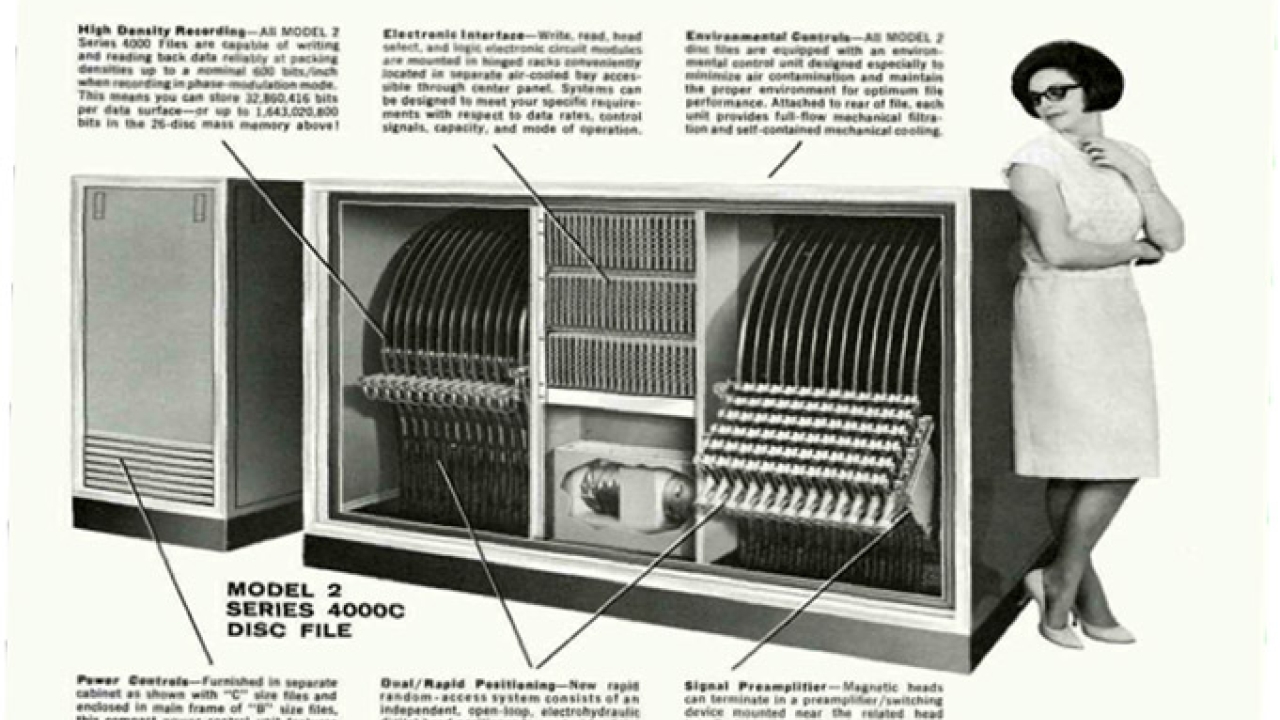

Pictured: Early data storage and retrieval systems were extremely large with limited capacity compared to digital computing technology. A modern iPhone has many times the storage capacity of this system

This article was published in L&L issue 5, 2011

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.