Cartonnages Larré streamlines workflow with EskoArtwork

French packaging printer, Cartonnages Larré, has increased the efficiency of its prepress workflow after installing EskoArtwork’s Automation Engine 10 at its Bayonne plant, and is one of the first European printers to adopt EskoArtwork's next generation of prepress workflow management software.

The upgrade to Automation Engine is part of a global performance improvement process at Cartonnages Larré. ‘We saw a demonstration of Odystar, EskoArtwork's automated prepress solution at drupa 2008, and were impressed by its interface and ease of use,’ explained Yann Bleiker, prepress manager, ‘and bringing together all of EskoArtwork's prepress workflow management tools seemed like a very sensible thing to do.’

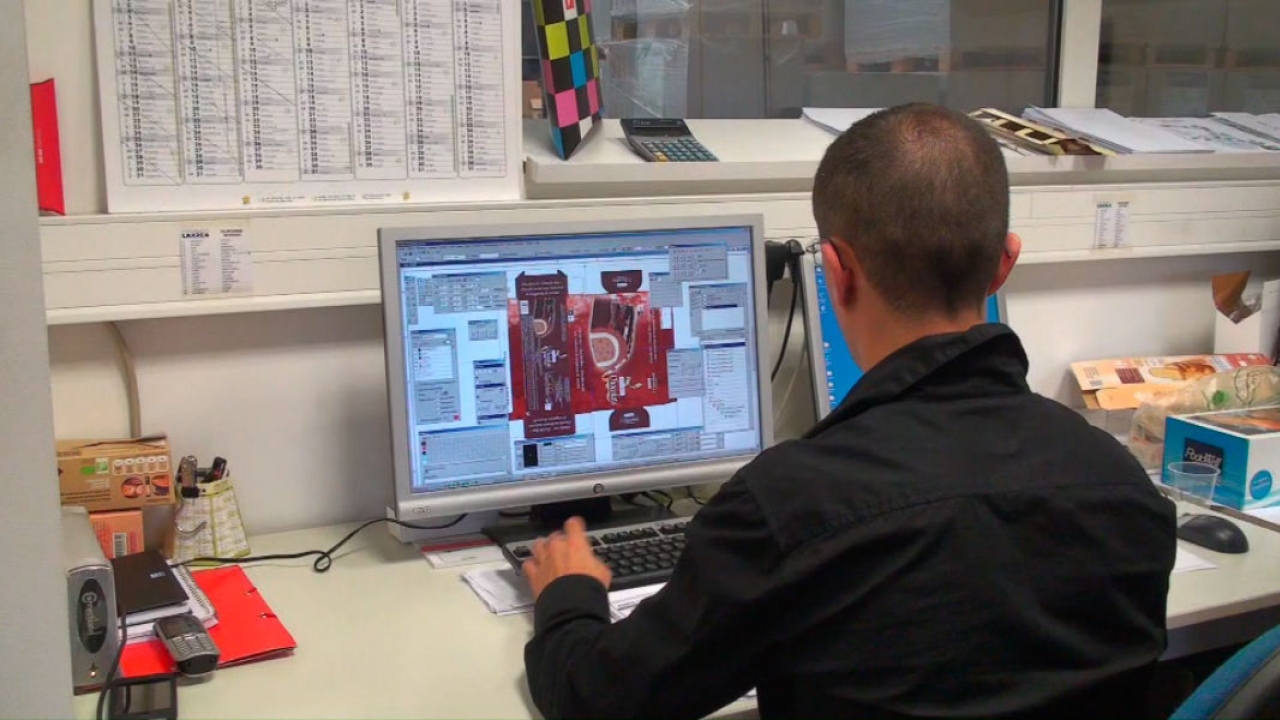

Cartonnages Larré was a beta test site for the new technology and decided to integrate the final version of Automation Engine in May 2010. The configuration includes a server and three client workstations. ‘Automation Engine allows us to simplify our procedures,’ added Bleiker. ‘Previously, we were using 20 different job ticket templates to cover the configurations we had in production. With Automation Engine, we’ve reduced this to two!’

Cartonnages Larré pushed things even further. ‘We are using an MIS system we developed in-house,’ commented general manager Hugues Larré. ‘We interfaced Automation Engine with our MIS system, allowing us to pass job parameters down to the prepress workflow manager automatically. This saves time and limits the risks of a typing error.’

Cartonnages Larré now has CTP in-house, an MIS system and Automation Engine, and this has reduced its prepress cycle from 48 hours to 15 minutes (to produce a set of printing plates).

The prepress workflow's high level of automation also allows operators to spend more time on file preparation and plate verification. It has increased throughput and customer service.

The company has a large customer base across diverse markets, including electronics, food, healthcare, textile and cosmetics, converting 7000 tons of carton board every year. Its 45 staff generate an annual turnover of €7 million, principally five and six-color work printed on manroland presses.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.