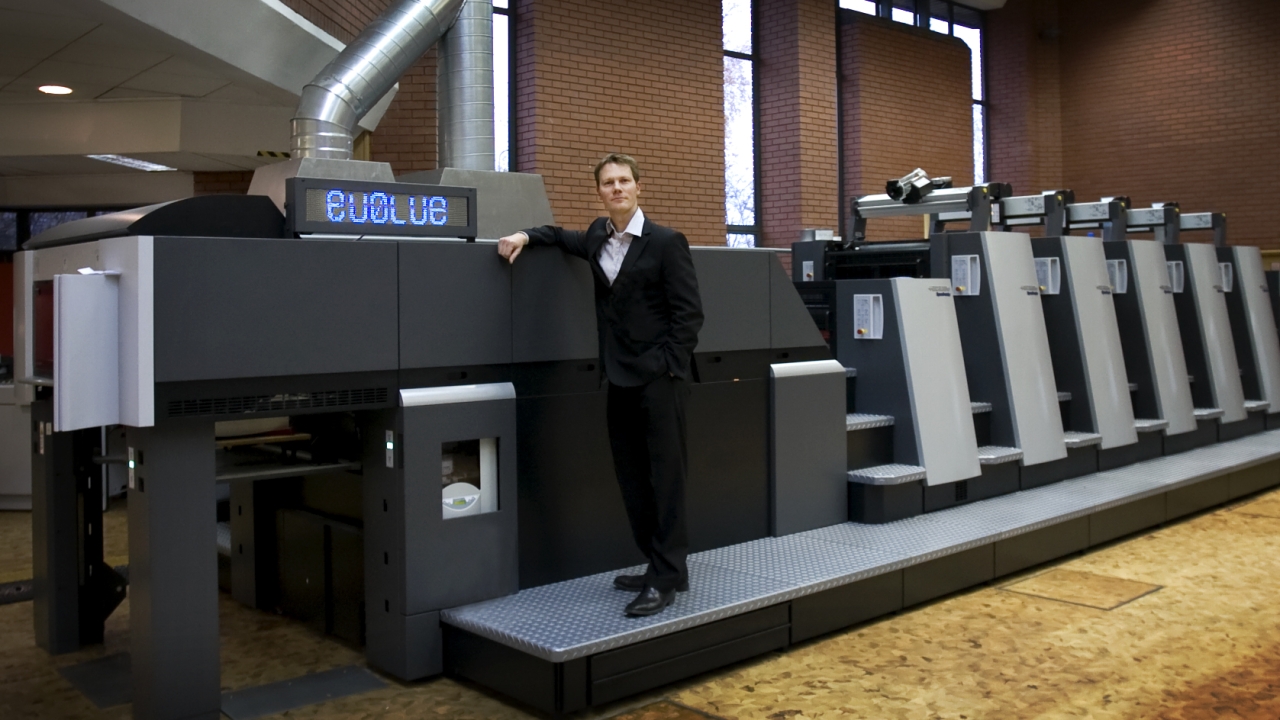

Evolve invests £1.2m to boost its retail and POS output

Rickmansworth (UK) based Evolve has completed a major tranche of investment with Heidelberg that is designed to add more retail and point of sale packaging to its portfolio. The newly installed Heidelberg Speedmaster XL 75-5+L, which is a five-unit press with dedicated coater, will boost Evolve’s capability to handle packaging work for prestige retail names like B&Q. The company has also added three additional staff.

The company specializes in design led, brand conscious work for service, retail, industrial, public and charity sectors. It offers a range of services including inline die cutting, and the new press will offer customers added value with gloss and special coatings that give brands an additional lift.

Also part of the investment program is Inpress Control, a highly automated registration and color measurement and adjustment tool. It speeds up make ready and reduces initial waste to about 100 sheets. Best of all, it allows exact color replication throughout a run and from run to run.

Reducing waste fits well with the company’s green policies, which already see it running processless plates to cut out chemistry, vegetable inks for the CMYK process colors, and FSC or PEFC Chain of Custody papers, whenever possible. The new Heidelberg will run 2-3% alcohol at start up but this will be soon be eliminated, and its modern energy efficient technology will also reduce Evolve’s power bill.

The Speedmaster’s enlarged cylinder enables it to handle thick stocks and gives good rolling power for solids. It easily fulfils the ISO 12647 color standards with closed loop colour between prepress and press that Evolve uses. The company works hard to ensure that brand colors are optimized, even when there is a change in stock, and with this data keyed into the Inpress Control, quality can be replicated.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.