GM set to launch finishing equipment at Labelexpo Europe 2023

Company will highlight premium label embellishments and more

‘We are really looking forward to showing visitors the many innovative ways that our machines can optimize their finishing process,’ said Uffe Nielsen, GM’s CEO.

‘Automation is driving profits and it is the key to growth. Our mission is to build automation into as many aspects as possible, whether that is through technology innovation, like the GM laser die-cutting module, or partnerships with other industry leaders, such as Cerm.’

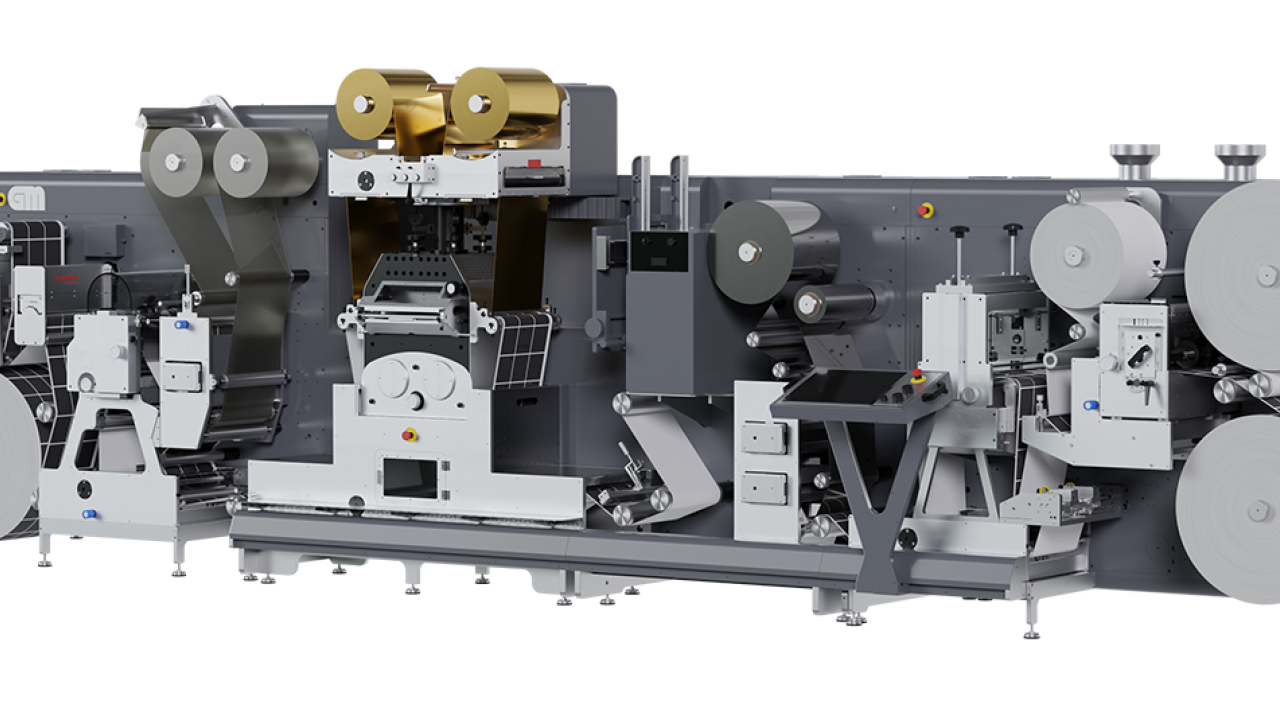

GM will highlight its highly automated DC350Flex+ wine line for premium label embellishment. Designed for adding maximum value to digital labels for luxury markets, particularly wine, spirits, cosmetics and beauty, it is noteworthy for its exceptional foiling and embossing capabilities and striking digital varnish effects.

The DC350+ Flex Wine features a 50-ton hot stamping module, which uses multiple foil streams. It also comes with an integrated Foil Saver which effectively reduces the wastage of costly foils, while GM’s QuickMount technology facilitates faster mounting of the embossing plates.

DC350Flex+ Wine will feature the DVM350 Digital Varnish Module, which uses the latest inkjet technology for digital embellishment. This is a faster, more flexible and cost-effective alternative to screen-printing for adding spot varnish, high-build tactile effects, including warning triangles and Braille, as well as metallics and holograms, all in one process.

‘Digital varnish and digital foil will shape the future of a highly competitive market in short to medium-run digital label printing,’ Nielsen said.

‘On the DC350Flex+ you get the option to add these capabilities with the fantastic DVM350 Digital Varnish Module, giving you tool-free operation, full flexibility in design, faster job changes, and lower costs. That really is a game-changer.’

GM is also introducing the DC350Flex+ that boasts a rotary die-cutting speed of 130m/min (or 80m/min in semi-rotary mode). The DC350Flex+ series offers complete customization options.

At the other end of the market, GM offers a range of compact and ultra-compact finishing machines. The show will demonstrate the power of the smallest offering, the DC350Nano, that features power, speed and flexibility, built into a small footprint.

A wider version of GM’s compact Hot Foil unit, the new HF350, will demonstrate an affordable and simple way of adding embossing and foiling effects. It can be set up as an independent embellishment unit or connected to a digital press or the DCMini compact label finisher, which will also be introduced at the show.

Visitors to the show can also see the the SR550 slitter inspection rewinder, which offers high-speed slitting up to 300m/min and 100 percent quality inspection; the LR250+ label camera inspection rewinder, which can be configured for pharma labels and even turned into a mini-inkjet digital press; the LR250 economical label inspection rewinder that comes as vertical tabletop model; the CC160S semi-automatic core cutter; and the CS350 high-speed sheeter.

In addition, the team will be handing out samples of functional labels equipped with RFID technology, allowing visitors to experience the capabilities of the new GM RFID lines firsthand.

‘It goes without saying that Labelexpo is a key event for this industry, and we always dedicate a lot of time, money, and effort to the show,’ Nielsen said. ‘For GM, it is all about getting the chance to speak with people and show them, in person, how our finishing lines with high levels of automation and connectivity can make a real difference to their business. While our video Tech Talks are a great way to demonstrate our fantastic machines, it will never replace the up-close-and-personal experience of visiting our Labelexpo stand and seeing them live.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.