CEFLEX issues first position paper

The Circular Economy for Flexible Packaging (CEFLEX), a collaboration of over 160 European companies representing the entire value chain of flexible packaging, has released its first position paper recommending the use of recyclable mono-materials.

As part of its Issue Alignment process CEFLEX stakeholders are working with Swiss University ETH to collect and assess topics which are essential to realizing a circular economy for flexible packaging. These issues are being addressed individually to create considered and aligned positions on each topic. The result has been its first position paper on ways to achieve this goal.

The first CEFLEX Position Paper recommends the use of flexible packaging made from recyclable mono-materials. The paper states the need to evaluate functional requirements of packaging and, when possible, to redesign existing flexible packaging to a recyclable mono-material.

This recommendation follows the recently released CEFLEX Designing for a Circular Economy guidelines, which provides practical advice and clarity on how to deliver significant environmental improvements without compromising functionality.

Flexible packaging, as with other sectors, requires a major change in collaboration as well as innovation and investment to achieve a circular economy. According to the consortium, only by working together can flexible packaging collectively achieve the ambitious sustainability goals, recyclability targets and prevent waste and pollution along the value chain.

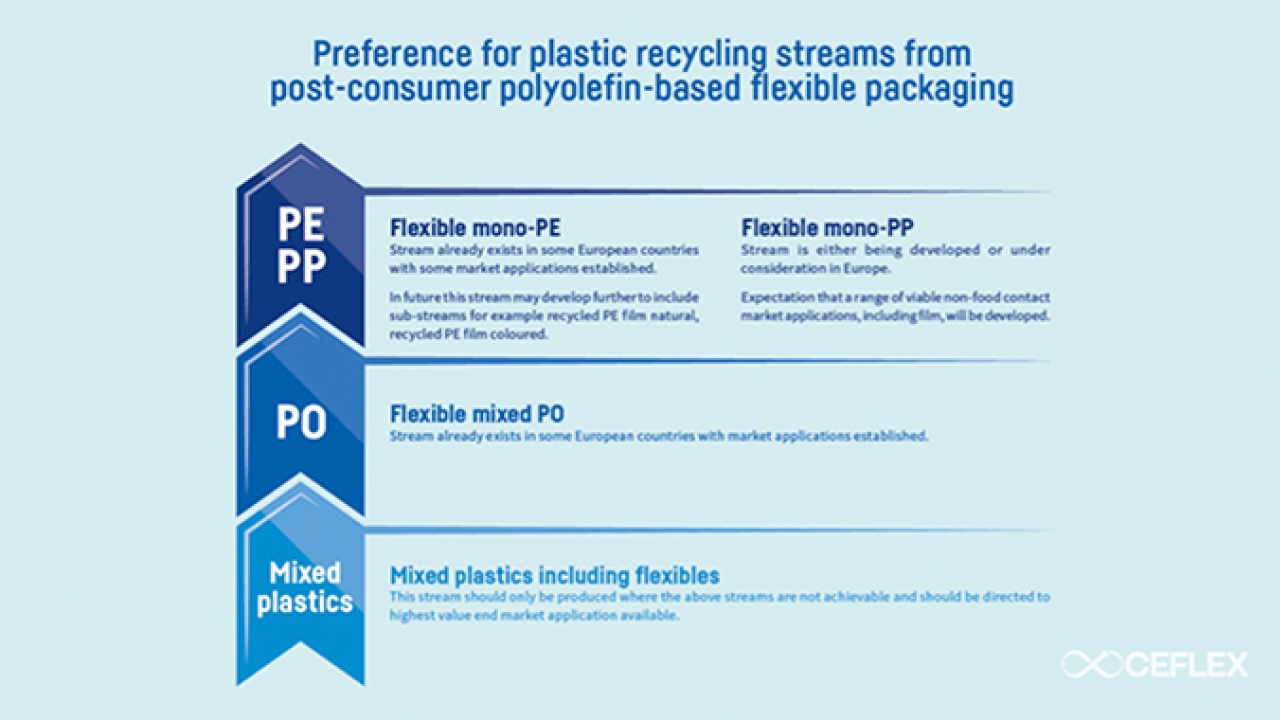

‘Ensuring packaging is designed to be recycled into new, valuable materials, or flows back into the economy, is a cornerstone condition for creating a circular economy,’ explained Graham Houlder, CEFLEX project coordinator. ‘More than 80 percent of flexible packaging is mono-material, Polyethylene (PE) or Polypropylene (PP) and we can grow this further, which will improve conditions for investment in infrastructure and help create sustainable end markets for the recycled materials.’

‘Quality mono-material inputs are key criteria for building a circular economy for flexible packaging,’ added Arne Jost of mtm plastics, member of the Borealis Group. ‘Implementing the CEFLEX Designing for a Circular Economy guidelines and this position paper work to increase the mono-material content in a bale of post-consumer film. This will be a welcome improvement for all recyclers and help accelerate end markets.’

The next priority for CEFLEX stakeholders is to examine collection models for flexible packaging in a circular economy and produce another position paper, after analysis of separate collection and post sorting of residual waste.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.