GSE to showcase Colorsat at Labelexpo Europe

GSE has confirmed it will introduce new flexibility to its range of Colorsat ink dispensing systems that achieve brand spot colors for labels and packaging. The company also extends its software with new functionality for managing color and optimizing ink logistics.

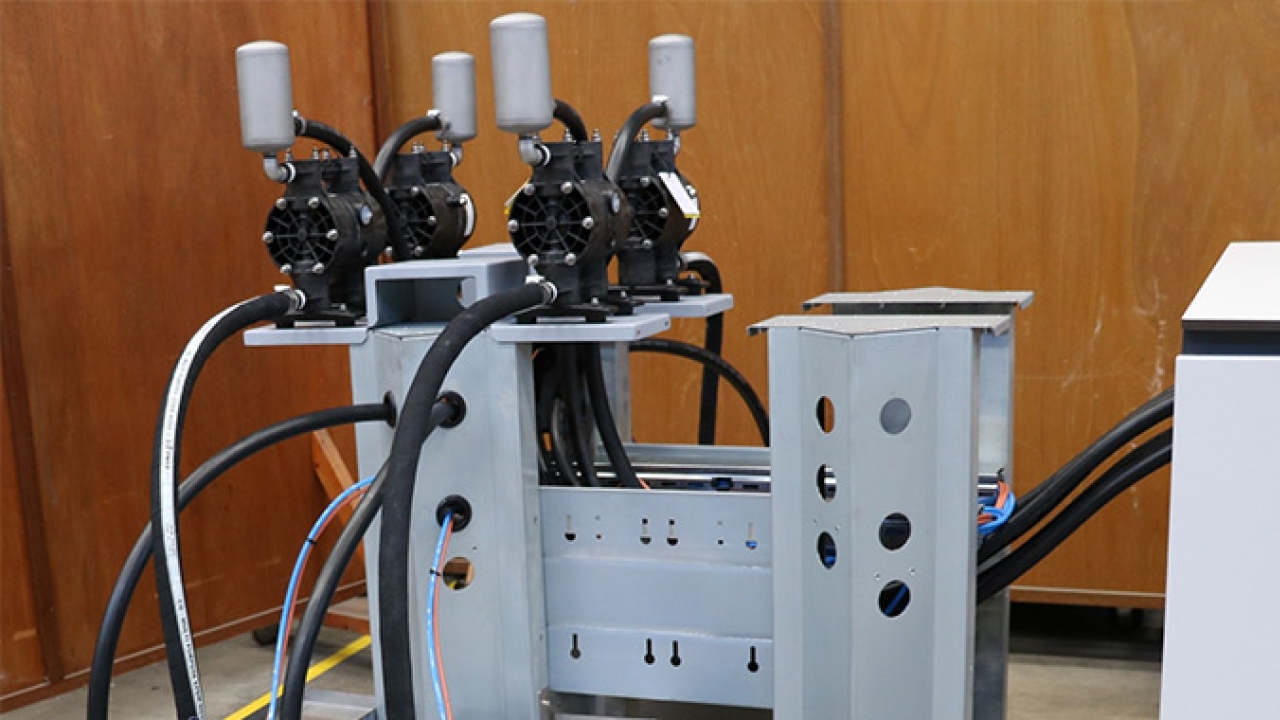

The company’s Colorsat ink dispensing systems feature a redesigned, lightweight, slim frame for base components. This provides more space for pumps, agitators and heaters to optimally maintain sensitive inks that are connected to the dispenser.

Maarten Hummelen, marketing director at GSE, commented: ‘The improved modular design of the Colorsat dispenser backbone enables printers to adapt the ink kitchen to meet changing requirements, such as reformulations or a transition to a new ink set, with minimal disruption.’

Additionally, ink pumps are located separately from the base ink containers. This, according to GSE, enables easier container exchange, ideal for traceability purposes. It also allows the choice of larger pumps for pumping and circulating high-viscosity inks or larger volumes. Complementing the enhancement to the dispensing program are new optional wireless and QR code scanners for booking in base inks from the ink manufacturer and inks returning from the press.

GSE’s program of automated Colorsat ink dispensers cut out waste, errors and delay in color preparation - potentially cutting ink consumption by up to 30 percent. They are tailored to volume and application needs, and are available for UV, LED-UV, low-migration, water-based and solvent ink sets, and flexo, gravure and screen processes. On display at the stand is the tabletop Colorsat FCS manual dispenser, suited for small-scale dispensing.

GSE also introduces extensions to GSE Ink manager, a software package with multiple programs that streamline ink-related processes in the workflow to save costs, improve responsiveness and enable compliance in safety-sensitive markets. It includes optional programs for efficiently reusing press return inks, making color corrections and adjustments, purchasing, and tracing ink batches through the supply chain. Additionally, reporting programs allow real-time stock control and job costings.

At the show, the company will highlight the GSE Ink manager’s ability to integrate with other software packages used for managing the printer’s workflow, saving time and eliminating double-entry. There will be demonstrations of a new interface with Cerm’s ERP platform using the GSE MIS connect package and an interface with color formulation software using GSE Color connect, together with an X-Rite spectrophotometer.

GSE is also introducing a new software feature for independently programming the agitation and circulation of inks, new web-based management reports and enhancements to the return ink management module.

‘In the face of rising raw material prices, political instability and disrupted supply chains, it is paramount that label and packaging converters make internal processes as efficient and flexible as possible. GSE’s modular ink dispensing and software solutions address these challenges, stamping out waste and delay through automating processes - leading to reduced ink consumption and more production time, added Hummelen. ‘Visitors are advised to book a consultation at the stand to discover how ink logistics can contribute to protecting profit margins and maintaining a competitive edge in uncertain times.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.