Meteor Inkjet and GIS support Xaar Nitrox integration

Meteor Inkjet and Global Inkjet Systems (GIS) have announced their support for the Xaar Nitrox printhead with a selection of comprehensive software and electronics for OEMs and integrators to minimize their time to market when launching new printers.

Xaar has worked closely with its partners to ensure that ‘plug in and print’ support is available for OEMs as soon as possible.

‘The support and collaboration of key software suppliers such as GIS and Meteor have ensured that OEMs from almost any sector will immediately be able to explore and reap the rewards from Nitrox’s enhanced performance and productivity,’ commented Graham Tweedale, general manager of Xaar’s printhead business unit.

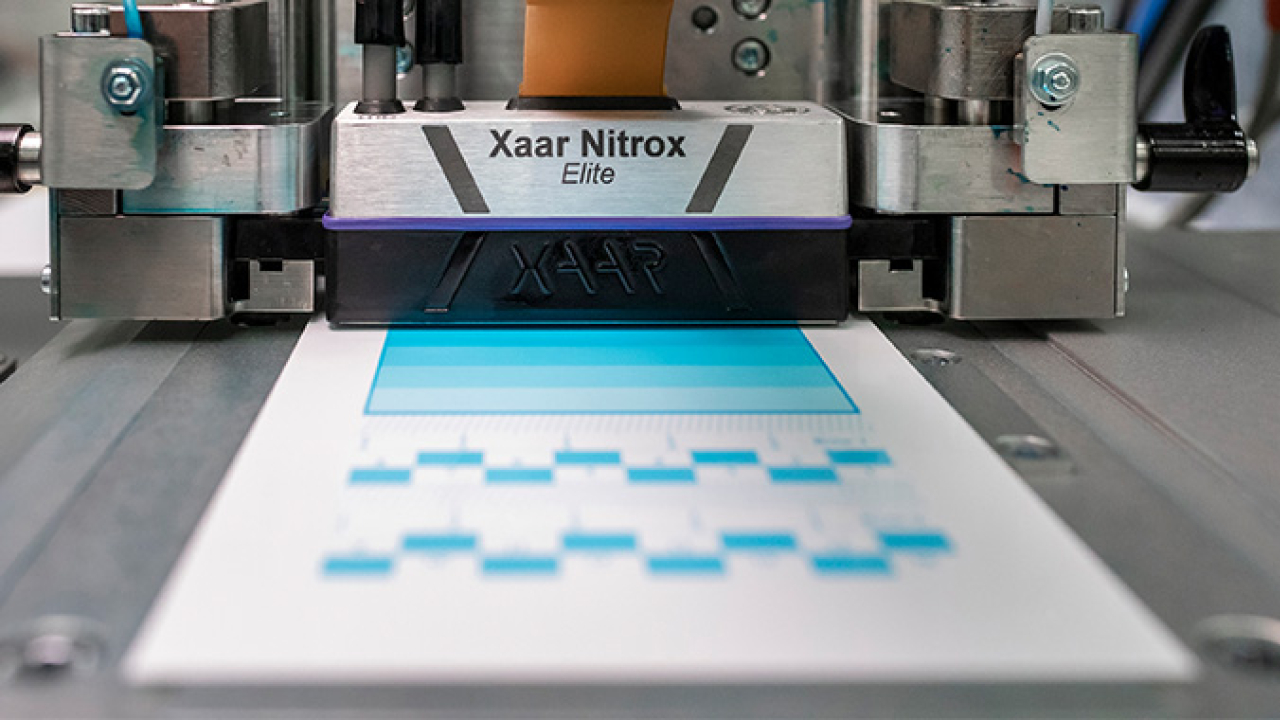

The Xaar Nitrox is available in three variants – Core, Pro, and Elite – providing customer choice and flexibility for various print needs. With firing frequencies of up to 48kHz, and print speeds exceeding 100 m/min, the Xaar Nitrox is designed to deliver a broader range of uses.

The printhead supports a wide range of applications and handles a broad range of fluids. High Laydown technology delivers high volumes of ink in a single pass and, combined with Xaar’s TF technology, allows fluids with higher particle loading and sizes, even with viscosities of up to 100 centipoise, to be used. This enables the Xaar Nitrox to print an increased color gamut and special effects for applications in the ceramic, glass, and packaging sectors, as well as jetting higher molecular weight materials.

Clive Ayling, Meteor’s managing director, said: ‘Since 2008, Meteor has worked with Xaar to offer customers scalable and reliable printhead driving solutions. Supporting all versions of the Nitrox printhead, our powerful, production-ready electronics and comprehensive suite of software ensures OEMs can be up-and-running quickly while taking full advantage of the Nitrox high-laydown, high-speed technology in a wide variety of applications.’

‘Our latest driver electronics will fully enable the cutting-edge capabilities of this new printhead, and this, alongside the ability of our ink supply system to support the potential high flow rates, will enable OEMs to gain maximum productivity,’ added Nick Geddes, managing director at GIS.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.