Phoseon Technology joins Sustainable Packaging Coalition

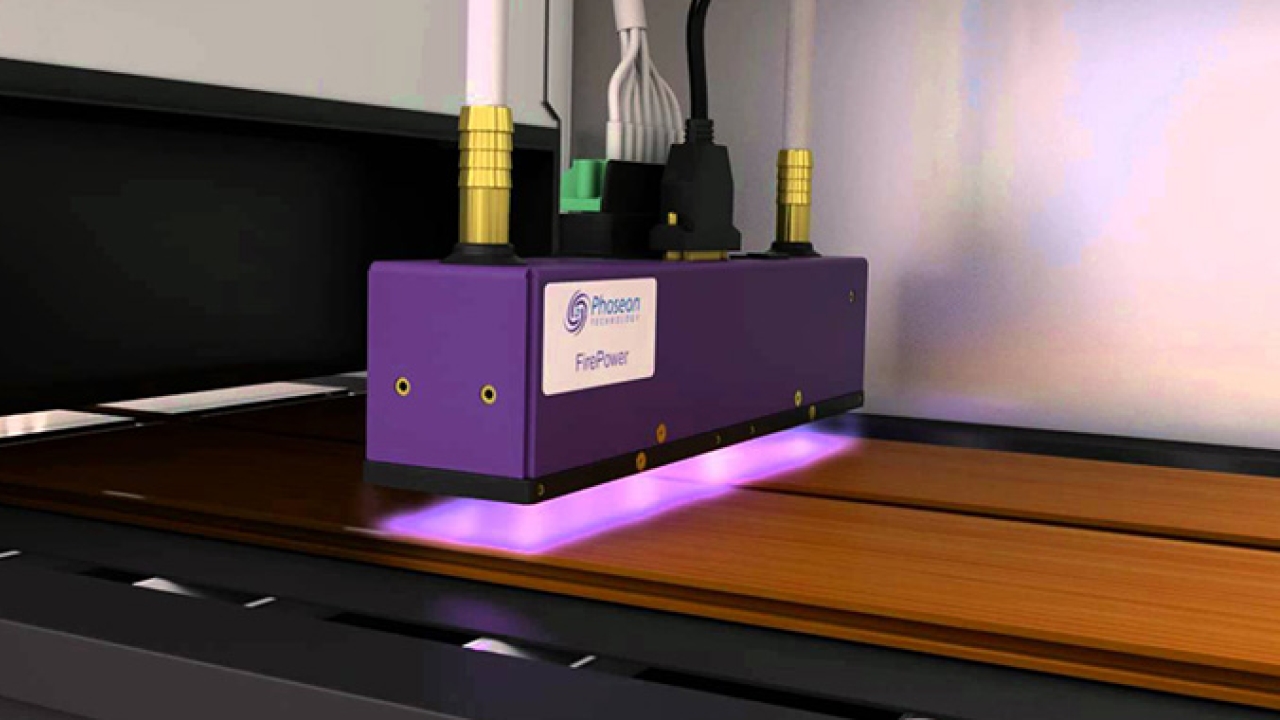

Phoseon Technology, one of the UV LED curing leaders, has joined the Sustainable Packaging Coalition (SPC) dedicated to creating more sustainable packaging that is good for the environment while being practical for people.

The SPC is a membership-based collaborative that believes in the power of industry to make packaging more sustainable and is one of the leading voices on sustainable packaging.

‘At Phoseon, we are fully committed to the well-being of the environment and continuously work to reduce the environmental impact of the products that we manufacture. In 2002, Phoseon pioneered the use of LED technology for UV curing to replace traditional toxic mercury bulbs from the curing process. Phoseon LED products provide significant energy savings, prevent pollution, and reduce waste. Collectively, Phoseon UV LED lamps have eliminated millions of pounds of CO₂ emissions,’ said the company in a statement.

With traditional UV curing processes, the tremendous heat associated with mercury UV lamps require a significant amount of electricity to operate. According to Phoseon, UV LED technologies provide energy savings up to 85 percent compared to traditional mercury-vapor UV lamps. With Phoseon light sources, there is no need for fume extraction units to remove the gases generated by mercury-vapor UV lamps.

‘By joining the SPC, we are showing our commitment to manufacture environmentally sustainable products that save energy, eliminate greenhouse gases, and remove mercury waste from the UV curing process,’ said Bill Cortelyou, president, and CEO at Phoseon Technology. ‘This membership emphasizes our ongoing dedication to support customers that are creating sustainable packaging.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.