Trioplast invests in Comexi retrofitting service

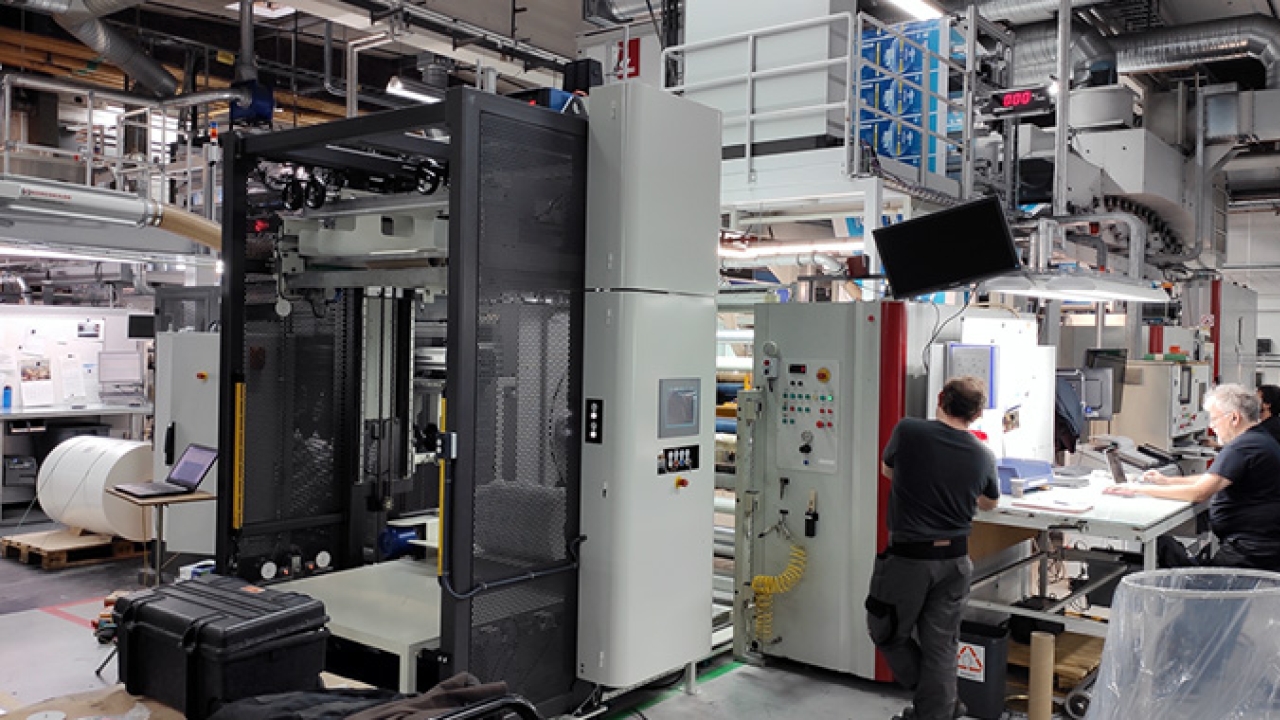

Swedish flexible packaging converter Trioplast has invested in an update of its Comexi machinery to enlarge equipment lifecycle and as a result increase the performance by 17 percent.

Comexi has performed several services on the four flexographic presses, which were acquired by the Swedish company between 2006 and 2008. These interventions combined a deep printing unit maintenance with the implementation of an inking system retrofitting, designed to refurbish currently installed Comexi machines. The equipment was modified with functional and constructive improvements, adapting the technological developments of last generation machines.

‘We have increased our productivity by 17 percent, as the printing speed is higher and production downtime have been reduced,’ said Dario Simic, maintenance and infrastructure manager at Trioplast. ‘After retrofitting quality has improved, and there is less reworking; printing presses are now optimized, and the department can be better planned.’

Comexi intends to introduce further adaptation measures at the Swedish company's facilities, with the aim to implement varied services, which have been unachievable, due to the Covid-19 pandemic.

Trioplast Group, founded in 1965, is one of the leading European companies on the flexible packaging market based on polyethylene films operating plants in Sweden, Denmark, France, and the Netherlands. Trioplast Group is dedicated to the production of films, bags, and protective foils, and sells its products to a variety of global markets, which includes industry, transport, and hygiene, among others.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.