All4Labels invests in GEW LED curing technology to minimize carbon footprint

Global packaging group upgrades production machines to decarbonize operations

An important step in the first ever Carbon Footprint Assessment (scope 1-2) will be the installation of the latest LED curing systems from GEW which will allow All4Labels to achieve a CO2 reduction of approximately 2,000 tons per year

All4Labels Global Packaging Group, one of the world’s leading label and packaging companies, has upgraded its production machines with the latest LED curing technology from GEW, one of the leading manufacturers of UV systems for label and narrow web printing, to decarbonize its operations.

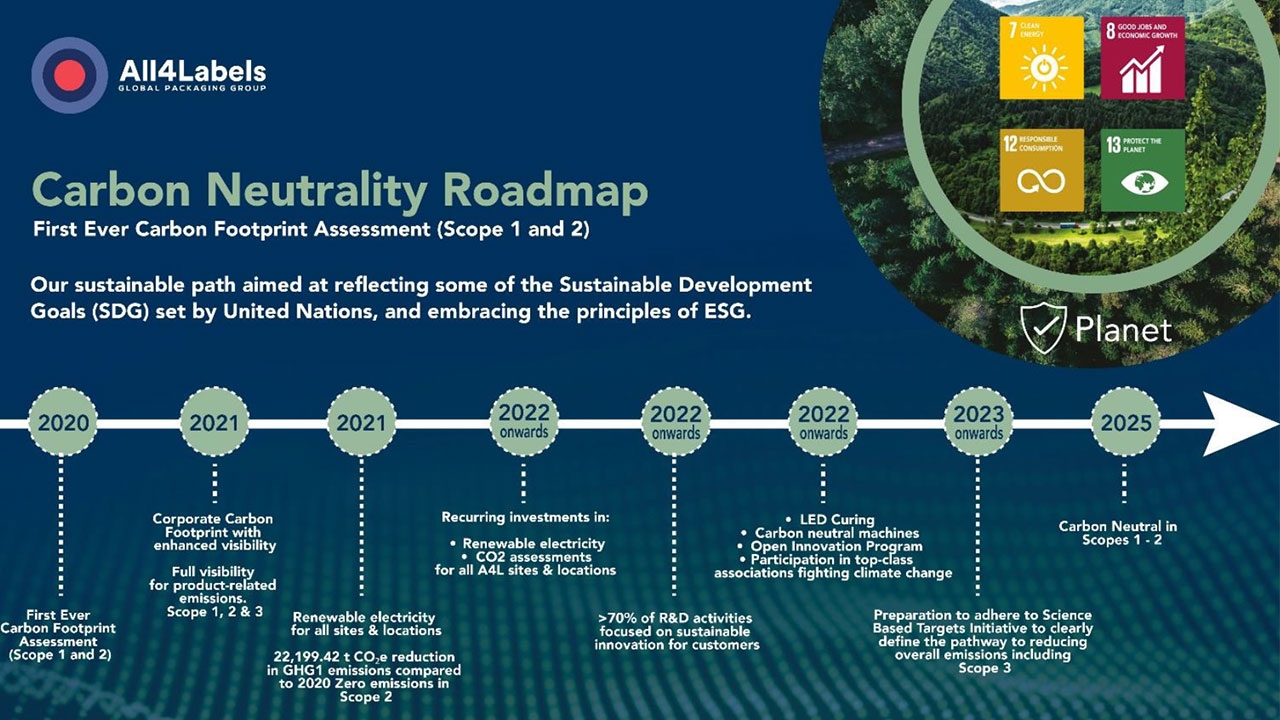

At All4Labels the commitment towards sustainability has continuously increased over the last years and the company has set precise goals and timelines within its global sustainability strategy, aimed at developing new initiatives and improvements to best protect people, planet, and to launch innovative products. Among the key targets of All4Labels ‘3Ps’ sustainable model, there is also the objective to become a carbon-neutral company and to play a significant role in climate change mitigation over the next 3 years.

To achieve this goal All4Labels is working to improve its environmental footprint, starting with a drastic reduction of CO2 emissions to mitigate the impact on global warming.

An important step in the first ever Carbon Footprint Assessment (scope 1-2) will be the installation of the latest LED curing systems from GEW which will allow All4Labels to achieve a CO2 reduction of approximately 2,000 tons per year, improve workplace safety and the reliability of its operations, and contribute to reducing mercury utilization across the entire value chain.

This upgrade program, which will also deliver important operational efficiencies to better satisfy customers, will start at the end of 2022 in Italy, Germany, and United Kingdom to be completed by 2023 across central and northern Europe by targeting more than 60 machines worldwide.

‘Our transition from UV to LED curing systems represents a milestone for the sustainable development of the labeling and packaging industry and is in line with the UN Sustainable Development Goals. We have decided to invest several million euros to upgrade our machines with the latest sustainable curing technology, which will ensure stable, fast, and efficient production at the lowest environmental impacts possible,’ commented Dr Guenther Weymans, chief operating officer at All4Labels.

Matthias Michel, vice president of global engineering at All4Labels, added: ‘In early 2020 we started several pilot tests to ascertain the technical feasibility of various LED curing systems for our production technologies. Since then, LED technology has significantly improved its lifespan capabilities, becoming able to provide constant, steady, and reliable curing in our printing operations. Based on the last technical results, we are now confident to invest in the LED technology to best serve the market with the most sustainable production technologies.’

‘After a thorough technical evaluation period, we are very proud that All4Labels have chosen GEW as their exclusive partner for this pioneering transition to UV LED. The project scope is the largest the world has seen to date, with 12 sites and over 60 machines being retrofitted to LED in phase 1. All4Labels were keen to capitalize on the environmental benefits of UV LED and the scope of this upgrade program will most certainly deliver huge savings in that respect,’ concluded Bernd Prattl, managing director at GEW DACH.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.