Aztec Labels boosts sustainability with Benford UV LED drying

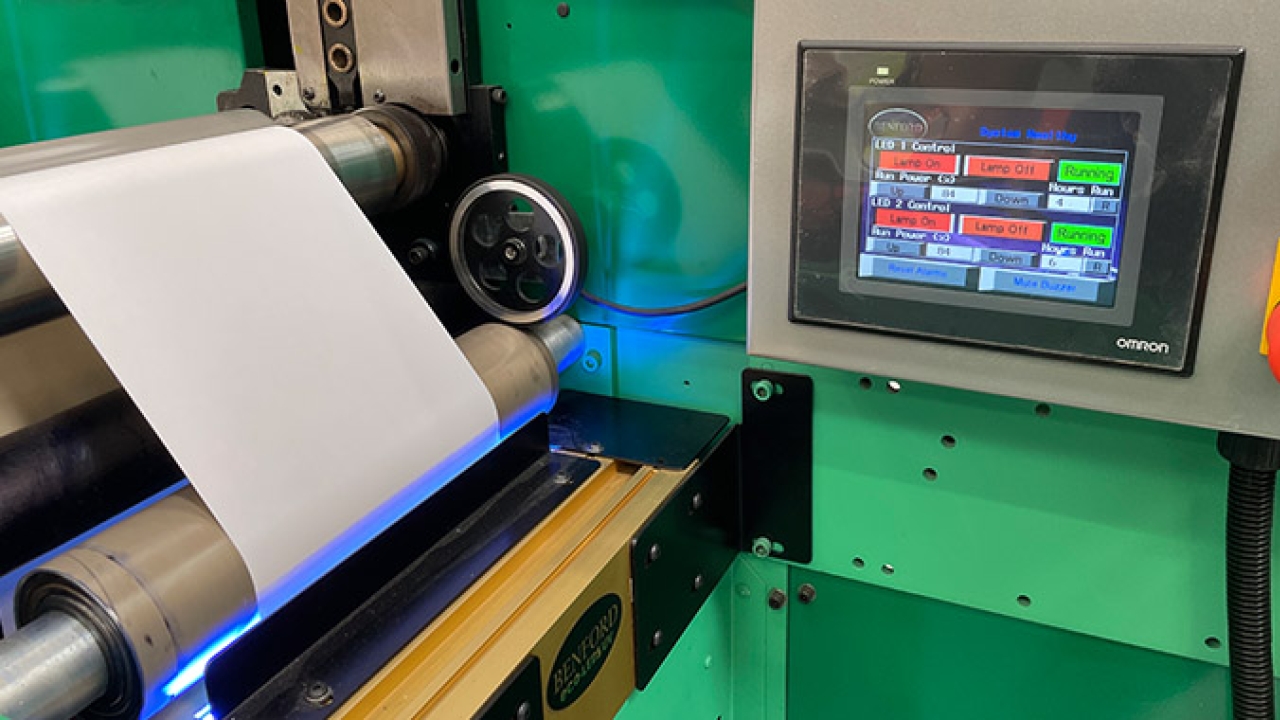

UK-headquartered label printer Aztec Labels has installed a Benford LED UV drying system on a 2-color press, with plans to implement this technology across the factory to boost its sustainability performance further.

‘As a provider of high quality, fast turnaround label solutions to the trade, we are always seeking to invest in the latest technology that provides a competitive advantage and improved quality and sustainability performance for our customers,’ commented Colin Le Gresley, managing director of Aztec Label. ‘Benford UV is renowned in the wide-format sheetfed printing industry for excellence in LED drying systems. Over the past five years, they have developed a new robust and high-tech LED UV dryer design that offers a number of benefits to us in narrow web printing. The advantages include improved consistency in print results, low operating costs, and importantly, the technology aligns to our overall sustainability objectives in optimizing our energy use.’

Marc Boden, founder of Benford UV, added: ‘Just like the team at Aztec, we are committed to boosting sustainability in our operations. Our High Wycombe, Buckinghamshire, facility runs on solar power; like Aztec, we have electric cars and are always seeking to develop new solutions that create efficiencies for our customers and benefit the planet.

‘The LED UV system we’ve installed at Aztec uses 30-35 percent less power than standard dryers with very little heat production, avoiding web distortion and boosting the quality and efficiency of the print process. We’re also incredibly proud that all the parts are British Made, apart from the chips manufactured in the Far East, adding to our sustainability credentials.’

Available in widths from 250mm/10in to 670mm/26in, Benford UV LED offers instant on/off capability, with no warming time, ensuring print consistency. The system is ozone and mercury-free and provides a deep cure for tricky metallics, white and black inks.

‘We’ve been impressed with the simplicity and safety of the design and that the energy output adjusts automatically to the press speed to ensure perfectly cured inks. The system has a compact design and continuous temperature and current monitoring, too, providing us with the confidence we needed to manage our drying process efficiently. With the price of LED inks dropping as production economies of scale increase at ink makers, I’m sure LED is going to be a technology of choice for a lot of printers moving forward. The results are impressive,’ concluded Le Gresley.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.